Qu'est-ce que la résistance à la traction ?

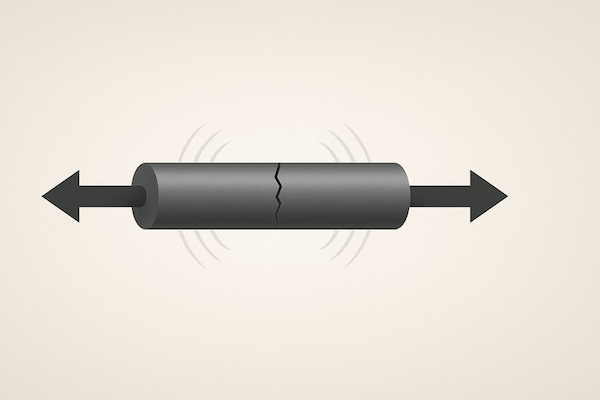

La résistance à la traction désigne la contrainte maximale qu'un matériau peut supporter lors d'un étirement ou d'une traction avant de se rompre. Il s'agit d'une propriété mécanique fondamentale, généralement mesurée en mégapascals (MPa) ou en livres par pouce carré (psi), qui représente la résistance du matériau à la rupture.

En termes plus simples, la résistance à la traction nous indique la force de traction qu'un matériau peut supporter avant de se rompre.

Résistance à la traction par rapport aux autres propriétés mécaniques

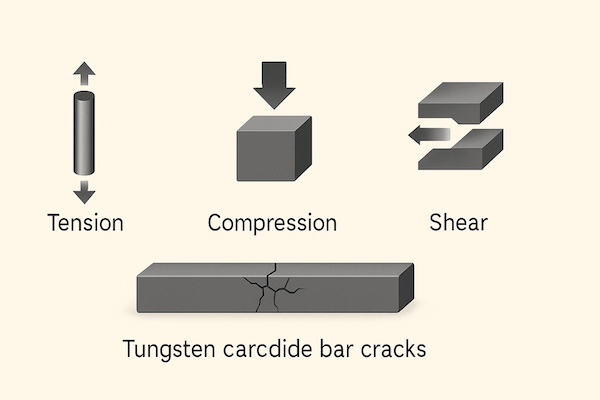

La résistance à la traction est souvent évoquée parallèlement à :

Résistance à la compression – résistance à l'écrasement ou à la compression

Résistance au cisaillement – résistance aux forces de glissement

Résistance à la rupture transversale (TRS) – couramment utilisée dans les matériaux cassants comme le carbure cémenté pour se rapprocher de la résistance à la flexion

Cependant, comme le carbure de tungstène est un matériau cassant, sa résistance à la traction est nettement inférieure à sa résistance à la compression, ce qui le rend plus sujet à la fissuration sous tension que sous pression.

Résistance à la traction du carbure de tungstène (carbure cémenté)

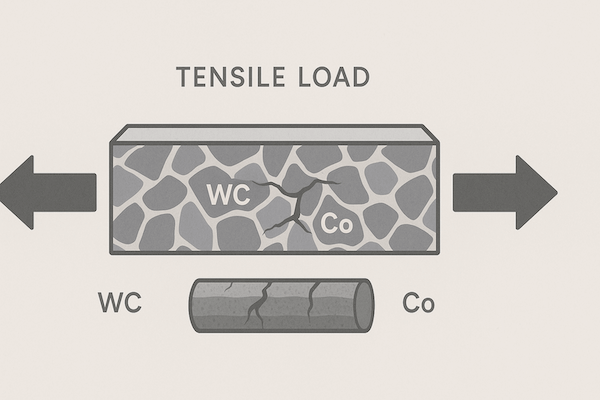

Le carbure de tungstène (WC) est combiné à un liant métallique (généralement du cobalt ou du nickel) pour former du carbure cémenté, un matériau connu pour ses propriétés exceptionnelles. dureté et sa résistance à la compression. Cependant, sa résistance à la traction est relativement modérée, généralement de l'ordre de :

250–700 MPa, selon la nuance et la composition du liant

Cela est dû au fait que les particules de WC semblables à de la céramique sont résistantes mais cassantes, et que les fissures peuvent se propager rapidement sous une charge de traction.

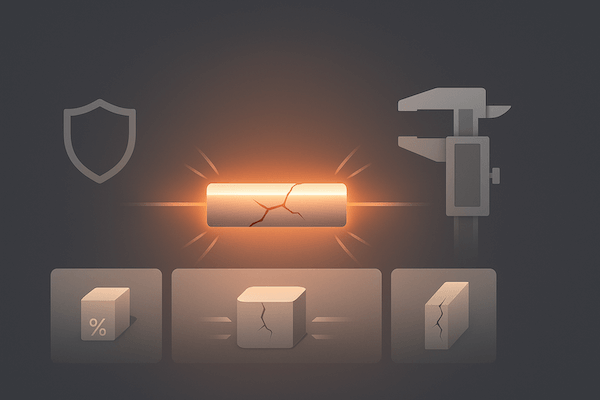

Facteurs affectant la résistance à la traction du carbure cémenté

Plusieurs variables liées aux matériaux et aux procédés influencent la résistance à la traction du carbure de tungstène :

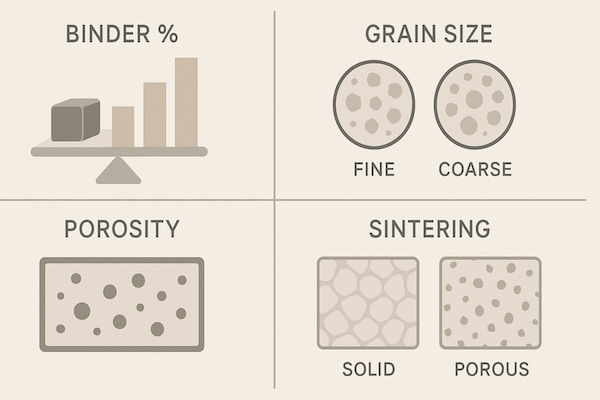

1. Liant Contenu

Une teneur plus élevée en cobalt augmente la ténacité et la résistance à la traction, mais peut légèrement réduire la dureté.

Par exemple:

Le YG20 (20% Co) offre une résistance à la traction supérieure à celle du YG6 (6% Co).

2. Taille des grains

Le WC à grains fins offre une meilleure résistance aux fissures, augmentant ainsi la fiabilité à la traction.

3. Porosité et défauts

La résistance à la traction est très sensible aux défauts internes. Les pores ou les inclusions peuvent concentrer les contraintes et provoquer des fissures.

4. Frittage Qualité

Les carbures bien frittés et entièrement denses présentent de meilleures performances sous des charges de traction et transversales.

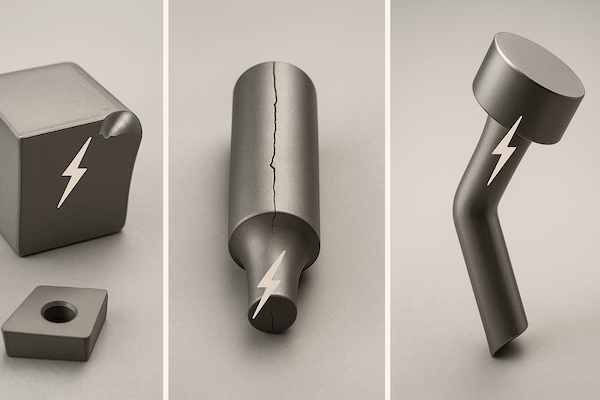

Pourquoi la résistance à la traction est importante dans les outils en carbure de tungstène

Même si outils en carbure de tungstène sont rarement soumis à une charge de traction pure, la résistance à la traction est néanmoins importante de plusieurs manières :

▸ Bris et écaillage d'outils

Un impact soudain, un serrage inégal ou une flexion inversée peuvent introduire une contrainte de traction, entraînant des fissures ou des fractures si le matériau n'a pas une résistance à la traction suffisante.

▸ Conception de la géométrie des outils

Les sections minces, les angles vifs ou les longues pièces en carbure en porte-à-faux sont plus vulnérables à la rupture par traction.

▸ Fatigue de vie

Cycles répétés de traction-compression (comme dans les machines à grande vitesse) coupe ou l'emboutissage) nécessitent des nuances de carbure avec une résistance à la traction équilibrée et dureté.

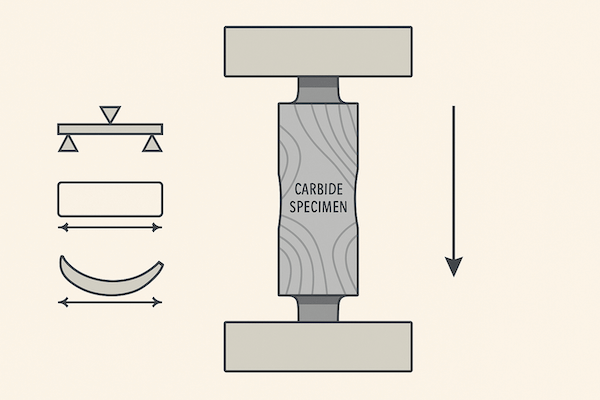

Essai de résistance à la traction du carbure

Les essais de traction sur des matériaux fragiles comme le carbure cémenté sont complexes. Les ingénieurs ont donc souvent recours à :

Essais de résistance à la rupture transversale (TRS)

Mesures de résistance à la flexion

Méthodes indirectes comme la mécanique de la rupture ou l'analyse de fatigue

Ils donnent des estimations pratiques de la résistance d’une nuance à la défaillance mécanique.

Applications pratiques et considérations

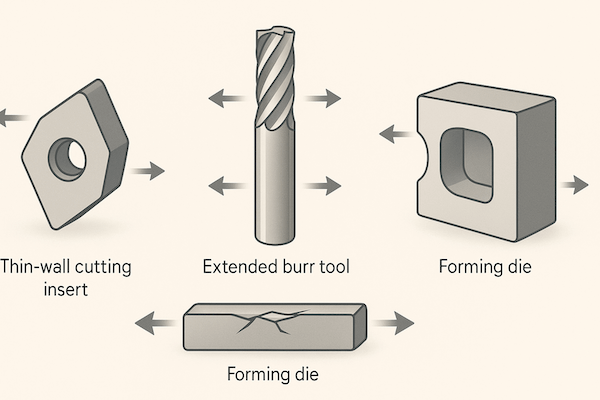

Les outils en carbure de tungstène utilisés dans les domaines suivants nécessitent souvent une résistance à la traction plus élevée :

Paroi mince outils de coupe en carbure et plaquettes en carbure

Limes rotatives, alésoirs en carbure, ou bavures sous de fortes vibrations

Outils de formage avec de longs porte-à-faux ou des portées non soutenues

Dans de tels cas, les ingénieurs sélectionnent des nuances avec une teneur en liant et une granulométrie optimisées pour améliorer la résilience à la traction sans sacrifier trop la dureté.

Conclusion

La résistance à la traction est une propriété essentielle, bien que souvent sous-estimée, des outils en carbure de tungstène. Si ces outils sont principalement appréciés pour leur résistance à la compression et à l'usure, une résistance à la traction suffisante est essentielle pour résister aux fissures, à la rupture et aux défaillances prématurées. Comprendre comment équilibrer la résistance à la traction avec d'autres propriétés comme la ténacité et la dureté est essentiel pour choisir la nuance de carbure adaptée aux applications hautes performances.