Sourcing tungsten carbide tips directly from manufacturers offers several advantages for businesses in industries like mining, construction, and machining.

Whether you’re looking to reduce costs, ensure quality, or strengthen supply chain relationships, working directly with manufacturers provides opportunities that third-party suppliers simply cannot offer.

In this blog, we’ll explore the key benefits of sourcing these essential tools directly from the manufacturer.

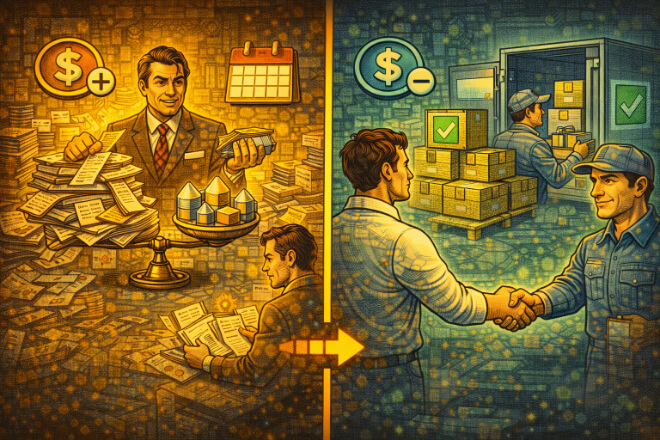

1. Cost Savings

When companies source tungsten carbide tips directly from the manufacturer, they bypass additional costs that third-party suppliers add.

These costs can include intermediary markups, storage fees, and shipping overheads. By eliminating these extra layers, manufacturers are able to offer lower prices compared to distributors or resellers.

For businesses that rely on large volumes of carbide tips, these savings can add up substantially over time.

In addition, direct purchasing helps companies optimize their supply chain, reducing unnecessary expenses related to middlemen.

By working closely with manufacturers, businesses can negotiate better pricing based on volume, while also ensuring that the cost of product customization is factored into the overall cost structure.

2. Enhanced Quality Control

One of the primary advantages of sourcing tungsten carbide tips directly from manufacturers is the ability to ensure higher product quality.

Manufacturers have full control over the production process, from the raw materials they use to the final product inspection.

This allows them to maintain stringent quality standards and minimize defects, something that may be harder to control when dealing with third-party suppliers.

Companies sourcing directly can also request certifications or reports from the manufacturer that provide transparency into the production processes, ensuring that the carbide tips meet the required specifications.

This helps avoid surprises, such as receiving substandard products, and allows businesses to rely on the manufacturer for consistent quality in every order.

3. Customization Options

Every industrial application can have unique requirements when it comes to tungsten carbide tips.

Sourcing directly from the manufacturer allows businesses to access a higher level of customization than when working with intermediaries.

Manufacturers can tailor their products to meet specific needs, including adjustments to the size, shape, coating, and material composition of the tungsten carbide tips.

For example, manufacturers may offer custom coatings for tips used in high-temperature environments, or they may provide tips with specialized geometries for particular cutting or drilling tasks.

This level of customization ensures that the tools are optimally suited to the job at hand, leading to better performance and extended tool life.

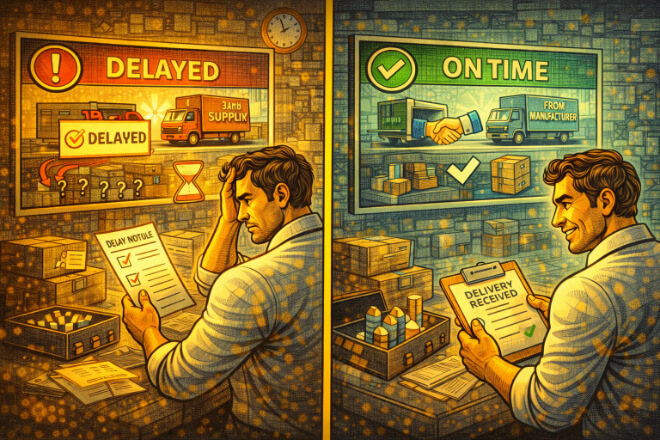

4. Faster Lead Times

Lead time is a critical factor for industries that rely on quick turnaround times, such as construction, mining, and machining.

Sourcing directly from manufacturers can significantly shorten lead times since companies are dealing with the source of the product.

Without third-party involvement, communication is streamlined, and the order processing time is quicker.

Direct contact with the manufacturer also enables businesses to place emergency orders or adjust production schedules to meet tight deadlines.

Manufacturers can provide more flexible timelines, ensuring that businesses receive their tungsten carbide tips as quickly as possible, avoiding delays that can occur when working through a distributor.

5. Direct Communication and Stronger Supplier Relationships

Directly sourcing from manufacturers fosters better communication and stronger supplier relationships.

Instead of dealing with intermediaries, companies can engage directly with manufacturers to discuss specific needs, address concerns, and request adjustments.

This direct communication facilitates a clearer understanding of expectations and leads to faster resolution of any issues that may arise.

Additionally, working directly with manufacturers builds trust and collaboration. Companies can develop long-term relationships that lead to more favorable pricing, priority order processing, and even exclusive product offerings.

These stronger ties also help businesses stay informed about new products or technological advancements in tungsten carbide tools.

6. Access to the Latest Innovations

Manufacturers are typically at the forefront of product innovation, constantly researching and developing new solutions to improve the performance and longevity of outils en carbure de tungstène.

When sourcing directly from these manufacturers, businesses gain access to the latest advancements in carbide tip technology.

For example, manufacturers may develop new types of coatings, alternative binder materials, or more efficient production methods that improve wear resistance, reduce heat generation, or increase cutting speed.

By sourcing directly, companies can be among the first to benefit from these innovations, gaining a competitive edge in their respective industries.

7. Reliable After-Sales Support

Sourcing directly from manufacturers ensures that businesses have access to reliable and specialized after-sales support.

Whether it’s troubleshooting issues, requesting maintenance advice, or dealing with warranty claims, manufacturers typically offer more comprehensive support than third-party suppliers.

Since manufacturers have a deeper understanding of their products, they can provide valuable insights into how to maximize the lifespan and performance of the tungsten carbide tips.

They can also assist with product replacements, repairs, or exchanges in case of defects, ensuring that businesses do not experience unnecessary downtime or loss of productivity.

Conclusion

Sourcing tungsten carbide tips directly from manufacturers not only saves costs but also enhances quality, offers customization, reduces lead times, and fosters stronger relationships with suppliers.

For companies in industries such as mining, construction, or machining, the benefits are clear.

By working directly with manufacturers, businesses can ensure they receive high-quality products tailored to their needs, helping them stay competitive and efficient.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.