Tungsten carbide tips are widely used in industrial applications due to their excellent dureté, résistance à l'usure, and durability. They are commonly found in cutting tools, drilling equipment, and other high-performance machinery.

These tips offer a variety of benefits, making them an ideal choice for industries that require precise, reliable, and long-lasting components.

In this blog, we will explore the advantages of using tungsten carbide tips in industrial applications and how they can help improve productivity, reduce maintenance costs, and enhance overall performance.

What Are Tungsten Carbide Tips?

Tungsten carbide is a compound made of tungsten and carbon, known for its hardness and durability.

Tungsten carbide tips are small parts made from this material, designed to be attached to tools for improving their performance.

These tips are used in a wide range of applications, including cutting, drilling, and grinding, where high résistance à l'usure is essential.

1). Composition of Tungsten Carbide

Tungsten carbide is made by combining tungsten (a metal) with carbon at high temperatures.

The result is a material that is incredibly hard and resistant to wear, making it ideal for tools and components exposed to harsh conditions.

Key Advantages of Tungsten Carbide Tips

Tungsten carbide tips offer several advantages over other materials in industrial applications. These benefits include:

1). Élevé Dureté

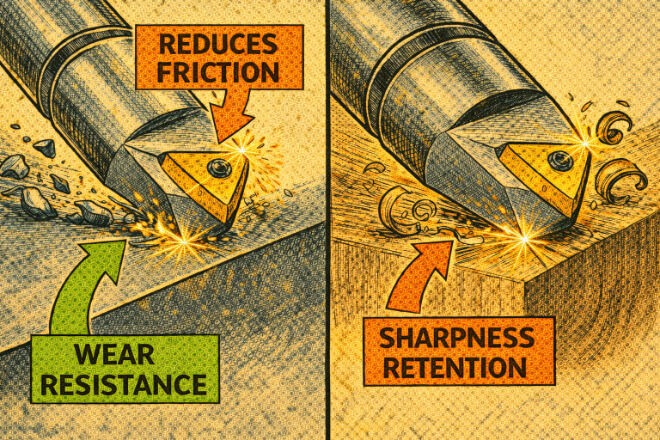

One of the most significant advantages of tungsten carbide tips is their extreme hardness.

Tungsten carbide is second only to diamond in terms of hardness. This allows the tips to maintain sharpness longer and resist wear in high-stress environments.

Tungsten carbide tips are highly resistant to wear and tear. In industries like mining, construction, and machining, tools are often exposed to abrasive materials.

Tungsten carbide tips are ideal for these environments as they can withstand constant friction and abrasive particles without losing their functionality.

3). Heat Resistance

Tungsten carbide has a high melting point, allowing it to maintain its strength and hardness even at elevated temperatures.

This makes tungsten carbide tips suitable for applications where tools are exposed to high heat, such as in cutting or grinding metal.

4). Impact Resistance

Due to their high densité and strength, tungsten carbide tips can absorb significant impacts without cracking or breaking.

This makes them ideal for heavy-duty applications, such as drilling or mining, where the tools are exposed to high forces.

Applications of Tungsten Carbide Tips

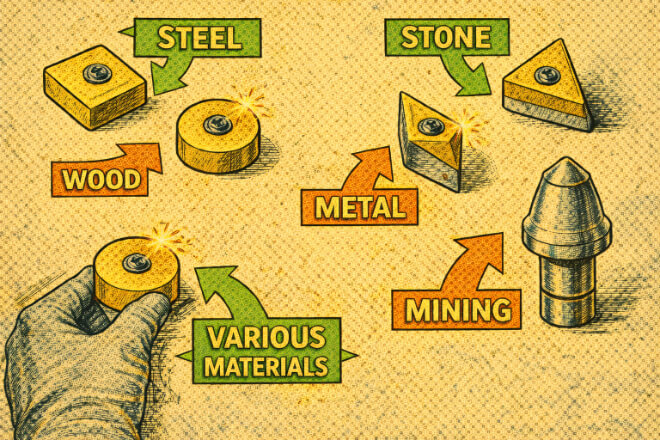

Tungsten carbide tips are used in a wide range of industrial applications due to their superior properties. Some common applications include:

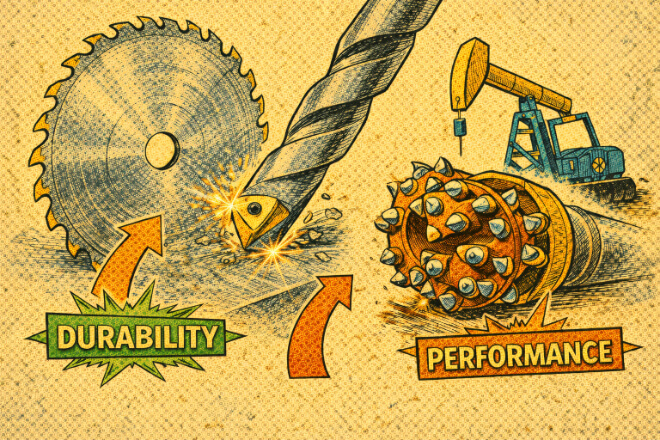

1). Outils de coupe

Tungsten carbide tips are widely used in cutting tools like saw blades, drill bits, and turning tools. Their dureté allows them to cut through tough materials such as metal, concrete, and stone with ease.

2). Exploitation minière Equipment

In the mining industry, tungsten carbide tips are used in drill bits, mining hammers, and other equipment.

These tools often encounter abrasive materials and harsh conditions, making tungsten carbide an excellent choice for extending tool life and reducing maintenance.

3). Pétrole et gaz Industrie

In oil and gas drilling, tungsten carbide tips are commonly used in drill bits that cut through tough geological formations.

The high hardness and résistance à l'usure of tungsten carbide help ensure that the drilling process remains efficient even in challenging environments.

4). Travail du bois et Travail des métaux

Tungsten carbide tips are also used in tools like routers, cutters, and grinders in woodworking and metalworking industries.

The tips help maintain sharpness and precision, improving the overall quality of the work being done.

Cost-Effectiveness of Tungsten Carbide Tips

While tungsten carbide tips may have a higher upfront cost compared to other materials, they are more cost-effective in the long run due to their extended lifespan and performance.

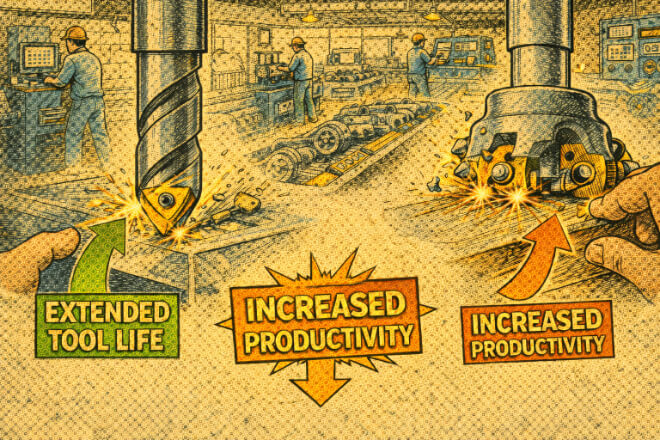

1). Reduced Tool Replacements

Tungsten carbide tips last longer than tools made from softer materials. This means fewer replacements are needed, reducing overall maintenance costs and downtime.

2). Increased Productivity

The durability and résistance à l'usure of tungsten carbide tips help maintain tool sharpness for longer, resulting in more efficient operations. This increases productivity by reducing the time spent on tool changes and maintenance.

3). Lower Total Cost of Ownership

Although the initial investment in tungsten carbide tips may be higher, the extended tool life and reduced downtime make them a cost-effective solution in the long term. This results in a lower total cost of ownership for the equipment.

How to Choose the Right Tungsten Carbide Tip for Your Application

Selecting the right tungsten carbide tip for your specific application is crucial for achieving optimal performance. Consider the following factors:

1). Material Compatibility

Make sure the tungsten carbide tips are compatible with the materials being processed.

Different grades of tungsten carbide are available for various applications, including those requiring higher résistance à l'usure or tougher materials.

2). Tip Shape and Size

The shape and size of the tungsten carbide tip should match the specifications of the tool and the application.

For example, a cutting tool may require a different shape than a drill bit, and the size of the tip should be selected based on the material hardness and cutting depth.

3). Conditions de fonctionnement

Consider the operating environment, including temperature, pressure, and load.

Tungsten carbide tips perform well in high-temperature and high-pressure environments, but certain grades may perform better depending on the specific conditions.

Conclusion

Tungsten carbide tips offer significant advantages in industrial applications that require high durability, wear resistance, and precision.

Their exceptional hardness, heat resistance, and impact resistance make them ideal for industries such as mining, oil and gas, woodworking, and metalworking.

By selecting the right tungsten carbide tips for your application, you can improve tool performance, reduce maintenance costs, and increase productivity, making them a valuable investment for high-performance tools.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.