Stainless steel is a tough and durable material, often used in industries like aérospatial, automobile, médical, and food processing.

But machining stainless steel can be a real challenge due to its dureté, dureté, and tendency to work-harden during cutting. That’s where tungsten carbide cutting tools come in.

Outils de coupe en carbure de tungstène are known for their hardness and wear resistance.

When used correctly, they can cut stainless steel efficiently while extending tool life and maintaining surface quality. However, even the best tools can underperform if not used the right way.

In this article, we’ll explore the best practices for using tungsten carbide cutting tools on stainless steel.

Whether you’re a shop owner, production manager, or manufacturing engineer, these tips can help you get better results and reduce machining costs.

Why Use Tungsten Carbide Tools for Stainless Steel?

Tungsten carbide tools are made by combining tungsten and carbon atoms into a very hard compound.

They are much harder than high-speed steel (HSS) and can handle high temperatures during cutting.

For stainless steel, tungsten carbide offers:

Haut résistance à l'usure

Better heat resistance

Durée de vie de l'outil plus longue

Ability to handle work-hardened materials

Clean and precise cuts

This makes carbide tools a better choice when working with tough metals like stainless steel. But just having the right tool isn’t enough. You also need the right approach.

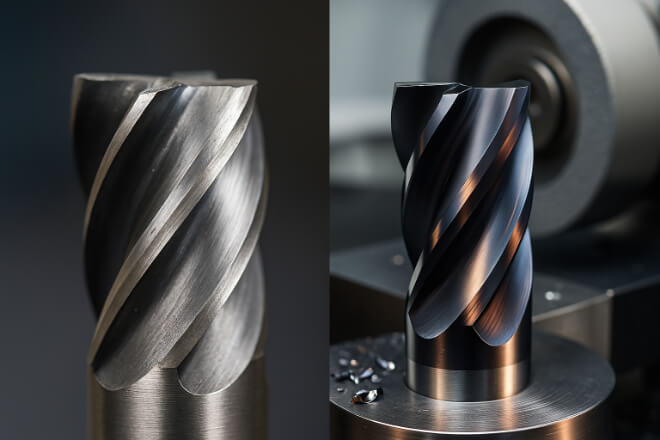

Choose the Right Tool Grade

Not all carbide tools are the same. They come in different grades depending on the balance of dureté et dureté.

For stainless steel, a slightly tougher grade is preferred to avoid tool chipping.

When selecting a grade:

Use medium-grain or fine-grain carbide for a balance of strength and hardness.

Choose coated carbide (like TiAlN or AlTiN) to resist heat and wear.

Avoid grades that are too brittle, especially for interrupted cuts.

If you’re unsure which carbide grade is best for your stainless application, check with the manufacturer or supplier.

Optimize Speeds and Feeds

Running carbide tools too fast or too slow can ruin your results. Stainless steel generates a lot of heat during machining.

You need to find a sweet spot where the tool cuts effectively without overheating or dulling.

Recommended practices:

Start with lower cutting speeds than for carbon steel.

Use higher feed rates to reduce contact time and heat buildup.

Monitor tool wear and adjust speeds/feeds accordingly.

Here’s a general guideline:

| Stainless Steel Type | Cutting Speed (m/min) | Feed Rate (mm/rev) |

|---|---|---|

| 304 (Austenitic) | 40–60 | 0.10–0.25 |

| 316 (Austenitic) | 35–55 | 0.10–0.20 |

| 410 (Martensitic) | 50–80 | 0.15–0.30 |

Use the Right Coating

A coating can improve tool performance by reducing friction and protecting against heat and wear. Coated tools last longer and deliver better finishes on stainless steel.

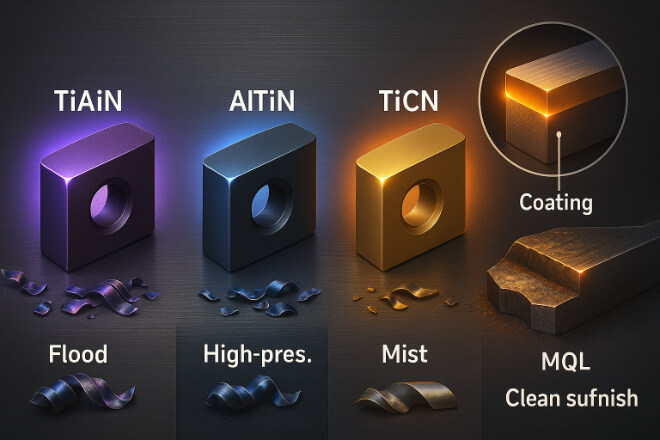

Common coatings for stainless machining:

TiAlN (Titanium Aluminum Nitride): Great for high-heat applications

AlTiN (Aluminum Titanium Nitride): Good for dry machining or minimal coolant use

TiCN (Titanium Carbo-Nitride): Offers excellent wear resistance and lower friction

Make sure the coating matches your cutting conditions—whether you’re running with coolant or dry, and whether your cuts are roughing or finishing.

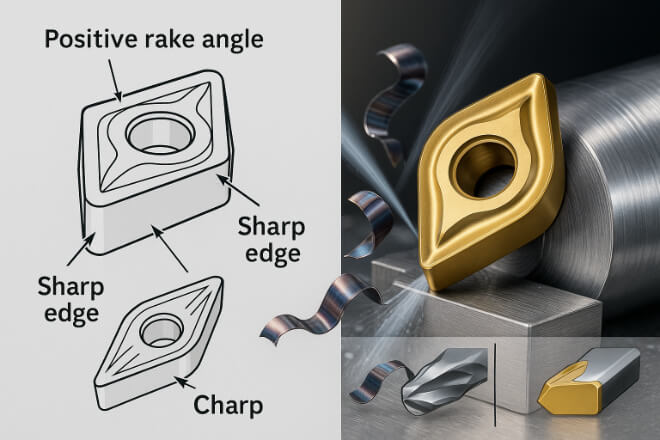

Ensure Proper Tool Geometry

Tool geometry directly affects chip control, heat generation, and cutting forces.

Using the wrong geometry can lead to poor surface finish, vibration, and fast tool wear.

For stainless steel, consider:

Positive rake angles to reduce cutting pressure

Sharp cutting edges for clean cuts and less heat

Chip breakers to prevent long, stringy chips

If your job requires frequent tool changes or you’re getting inconsistent finishes, it may be time to reassess your tool geometry.

Apply Coolant or Lubrication Properly

Stainless steel is known for poor thermal conductivity, which means the heat stays in the cutting zone. That’s why effective cooling is key when machining it with carbide tools.

Best practices for coolant:

Use flood coolant to keep the tool cool and prevent thermal cracks

For high-speed applications, high-pressure coolant may be better

In some cases, Minimum Quantity Lubrication (MQL) can reduce heat and improve finish

Never run carbide tools dry unless the tool and coating are designed for it.

Monitor Tool Wear Signs

Regular inspection helps you spot issues before they become costly. Even the best carbide tools eventually wear out.

Keeping an eye on wear patterns helps prevent tool failure and poor surface finishes.

Common signs of tool wear:

Edge rounding or chipping

Flank wear (on the side of the tool)

Crater wear (on the rake face)

Built-up edge from sticky materials

If you notice any of these, it’s time to regrind, replace, or adjust your settings.

Regrind Instead of Replace (When Possible)

Carbide tools can often be reground and reused. This helps reduce cost and waste, especially for larger or high-precision tools.

When regrinding makes sense:

The tool still has enough material left

You have access to precision grinding services

You want to maintain consistent performance without full replacement

Regrinding helps extend tool life and lowers cost-per-part. Always check with your supplier to see if regrinding services are available.

Avoid Common Mistakes

Here are a few common mistakes that lead to carbide tool failure when cutting stainless steel:

| Mistake | Why It’s a Problem | What to Do Instead |

|---|---|---|

| Using HSS tools for hard stainless | HSS dulls quickly | Use carbide tools with proper grade |

| No coolant or improper coolant | Causes thermal cracking | Use proper coolant strategy |

| Wrong geometry | Poor finish, fast wear | Use geometry suited for stainless |

| Ignoring tool wear | Leads to part defects | Inspect tools regularly |

Avoiding these issues will help your team save time, reduce scrap, and get better results on stainless machining jobs.

Réflexions finales

Using tungsten carbide cutting tools on stainless steel isn’t just about having the right tool—it’s about using it the right way.

From selecting the correct grade and coating to optimizing feeds and speeds, every detail matters.

With the right best practices, you can improve tool life, lower machining costs, and deliver consistent, high-quality parts.

If you’re looking for durable, high-performance carbide tools, check out Retopz. Their expert support and quality tools can help your shop get more done, with less downtime.