Introduction

À mesure que les usines et les industries se modernisent et se connectent, les outils de coupe doivent eux aussi évoluer. Les outils de coupe en carbure de tungstène sont déjà populaires dans de nombreux secteurs. Mais ils jouent désormais un rôle encore plus important dans la fabrication de pointe.

Dans cet article, nous explorerons l'avenir des outils en carbure de tungstène, comment ils sont améliorés grâce aux nouvelles technologies et comment ils soutiendront une production intelligente, rapide et durable.

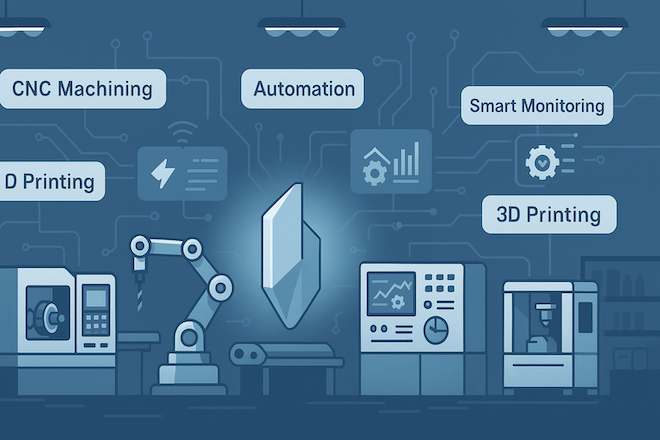

Qu'est-ce que la fabrication avancée ?

La fabrication avancée utilise des méthodes modernes, des machines intelligentes et des systèmes numériques pour fabriquer des produits. Elle inclut des technologies telles que :

Usinage CNC

Robotique

Automation

IoT (Internet des objets)

IA et surveillance des données

Impression 3D

Ces systèmes aident les entreprises à :

Gagnez du temps

Réduire les déchets

Fabriquer des pièces plus précises

Des coûts réduits

Soyez plus flexible dans la production

Pour suivre le rythme, les fabricants ont besoin d’outils robustes, fiables et précis, comme outils de coupe en carbure de tungstène.

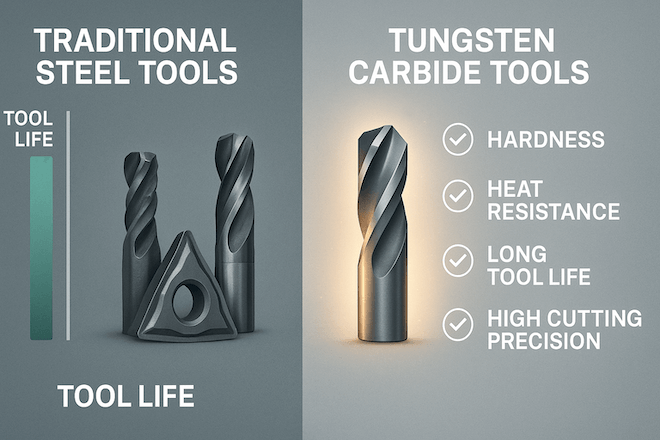

Pourquoi les outils en carbure de tungstène sont-ils toujours le premier choix ?

Le carbure de tungstène est composé de tungstène et de carbone, formant un composé extrêmement dur. Ses avantages incluent :

Haut dureté et la force

Résistance à l'usure et à la chaleur

Longue durée de vie

Bords tranchants pour des coupes de précision

Ces outils sont parfaits pour couper l’acier, l’aluminium, le titane, les composites et même le bois dans des machines à grande vitesse.

À Refaire, nous proposons une large gamme d'outils de coupe en carbure de tungstène qui sont reconnus dans plus de 50 pays.

Découvrez nos meilleurs outils :

Tendances futures des outils de coupe en carbure de tungstène

Voyons comment les outils en carbure de tungstène sont améliorés pour répondre aux besoins de fabrication de pointe.

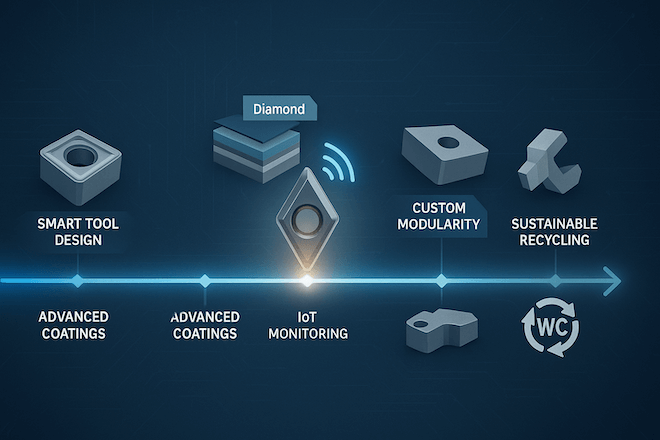

1. Conception d'outils plus intelligente

De nouvelles conceptions sont en cours de développement pour améliorer :

Évacuation des copeaux

Vitesse de coupe

Finition de surface

Les outils incluent désormais des trous de refroidissement internes, une géométrie à cannelures multiples et des profils hybrides pour un usinage plus rapide et une durée de vie plus longue.

2. Revêtements et technologies de surface

Moderne revêtements en carbure Prolonger la durée de vie des outils en carbure. Parmi les revêtements les plus courants, on trouve :

TiAlN (nitrure de titane et d'aluminium)

AlCrN (nitrure d'aluminium et de chrome)

Revêtements diamantés pour l'usinage des métaux non métalliques

Ces revêtements augmentent la résistance à la chaleur, réduisent la friction et aident les outils à mieux fonctionner à grande vitesse.

👉 Apprenez-en plus sur les revêtements dans notre glossaire technique du carbure de tungstène sur www.retopz.com

3. Surveillance des outils et retour d'informations

Dans les usines intelligentes, les outils sont associés à des capteurs et à des systèmes IoT pour suivre :

Usure des outils

Forces de coupe

Vibration

Température

Ces données permettent aux machines de savoir quand changer d'outil avant une panne. Elles contribuent également à améliorer les conditions de coupe futures.

4. Personnalisation et modularité des outils

À l'avenir, davantage d'usines demanderont des outils en carbure sur mesure, adaptés à leurs machines et matériaux. Avantages de la personnalisation :

Moins de temps d'arrêt

Meilleures performances de coupe

Coût total par pièce inférieur

À Refaire, nous offrons un support complet pour la conception d'outils en carbure personnalisés.

5. Durabilité et recyclage des outils

Le carbure de tungstène est recyclable (100%). Dans les usines de pointe, le recyclage des outils s'inscrit dans une économie circulaire. Les fabricants économisent de l'argent et réduisent leur impact environnemental grâce à :

Renvoyer les outils usés

Retraitement du matériau

Fabriquer de nouveaux outils avec du carbure recyclé

👉 Retop soutient la fabrication verte grâce à des outils durables et au recyclage des matériaux. Pour en savoir plus, consultez notre article : Comment les outils de coupe en carbure de tungstène favorisent une fabrication durable

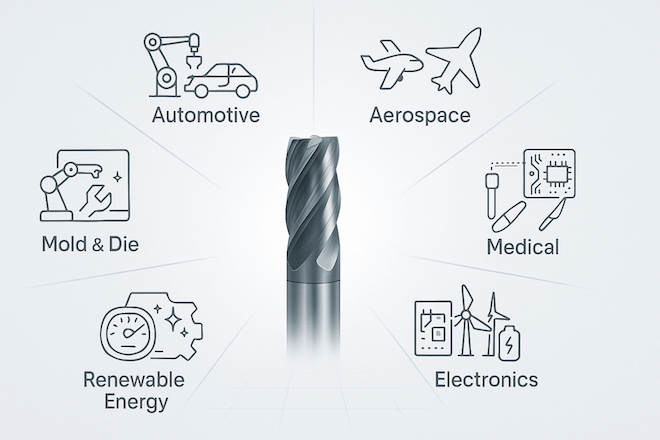

Les industries clés qui mènent l'avenir

Les outils en carbure de tungstène sont essentiels dans la fabrication de pointe dans tous les secteurs :

| Industrie | Applications d'outils |

|---|---|

| Automobile | Blocs moteurs, pièces de transmission, disques de frein |

| Aérospatial | Pièces en titane, aubes de turbine, châssis d'avion |

| Médical | Outils chirurgicaux, implants, forage de précision |

| Électronique | Routage de circuits imprimés, micro-usinage, emplacements de connecteurs |

| Moules et matrices | Moules d'injection, cavités de précision |

| Énergie renouvelable | Pièces d'éoliennes, boîtiers de batteries |

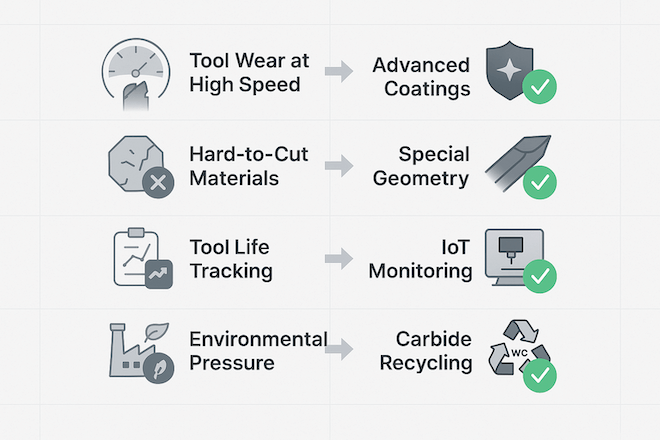

Défis et solutions

Même les meilleurs outils présentent des défis. Voici comment la technologie du carbure de tungstène les résout :

| Défi | Solution |

|---|---|

| Usure des outils à grande vitesse | Nouveaux revêtements et méthodes de refroidissement |

| Matériaux difficiles à couper | Géométries personnalisées, nuances de carbure plus résistantes |

| Suivi de la durée de vie des outils | Capteurs et porte-outils intelligents |

| Objectifs de durabilité | Programmes de recyclage et conceptions à longue durée de vie |

Ce que Retop fait pour l'avenir

Chez Retop, nous travaillons constamment sur les outils carbure de nouvelle génération. Voici comment nous contribuons à l'avenir de l'usinage :

Nuances de carbure hautes performances

Rectification et finition de précision

Géométries personnalisées

Développement d'outils spécifiques à l'application

Prototypage rapide d'outils personnalisés

Approvisionnement durable et recyclage

Nous aidons les fabricants à rester compétitifs dans les secteurs qui exigent une précision, une rapidité et une fiabilité élevées.

Conclusion

L'avenir des outils de coupe en carbure de tungstène est plus intelligent, plus rapide et plus durable. Avec le développement de la fabrication de pointe, les outils en carbure resteront la base de l'usinage haute performance.

Qu'il s'agisse de fabrication aérospatiale, automobile ou médicale, le choix du bon outil de coupe peut améliorer la qualité du produit, la disponibilité des machines et les performances environnementales.

Si vous êtes prêt à passer à la prochaine génération d'outils en carbure, contacter Retop aujourd'hui.