Tungsten carbide tips are known for high dureté and long service life. However, durability does not depend on carbide grains alone.

Binder content plays a key role in how strong, tough, and reliable a tungsten carbide tip will be. For decision-makers choosing cutting or wear tools, understanding binder content helps avoid early failure and unnecessary cost.

This article explains binder content in simple terms and shows how it affects durability in real applications.

What is Binder Content in Tungsten Carbide Tips?

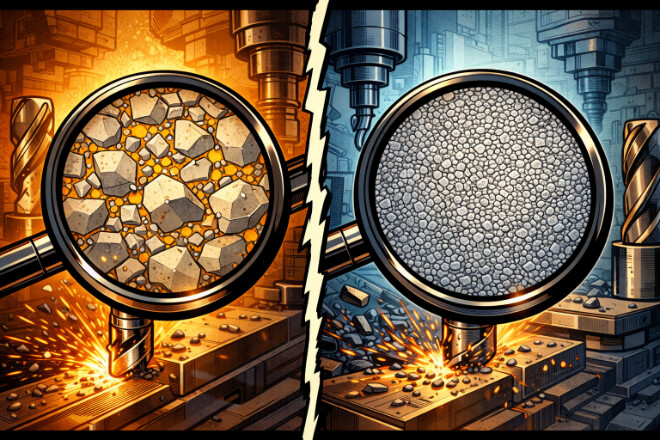

Binder content refers to the amount of metal matrix material (such as cobalt or nickel) that is added to the tungsten carbide grains during the manufacturing process.

Tungsten carbide, a ceramic material, is incredibly hard but also brittle. To enhance its dureté and provide some flexibility, a metal binder is used to hold the carbide grains together.

The binder content is typically expressed as a percentage of the total weight, and the higher the binder content, the more flexible the material becomes.

High Binder Content: This means there is more metal in the mixture, resulting in increased toughness and impact resistance. However, high binder content can reduce the dureté et résistance à l'usure of the tungsten carbide.

Low Binder Content: In contrast, lower binder content results in a harder material, which is more wear-resistant but less impact-resistant.

The right binder content is a balance between toughness and wear resistance, depending on the specific application and working conditions.

How Binder Content Affects Tungsten Carbide’s Hardness and Wear Resistance

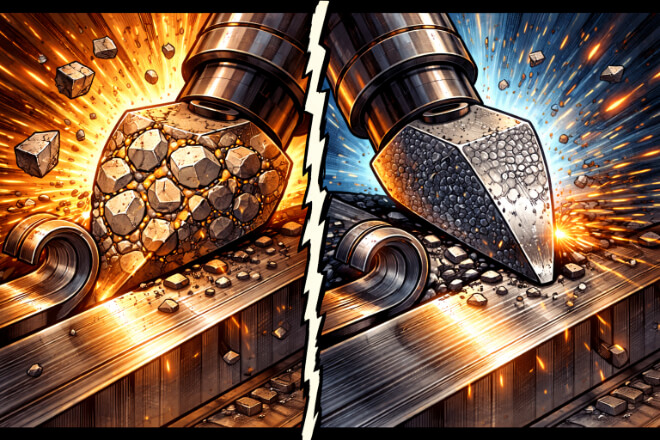

Binder content significantly influences the hardness and wear resistance of tungsten carbide tips. The amount of binder added can either improve or compromise the dureté et résistance à l'usure of the material.

High Binder Content:

While increasing dureté and impact resistance, a higher binder content reduces the overall hardness and wear resistance of tungsten carbide.

In applications where wear resistance is critical, such as in cutting or grinding hard materials, too much binder can lead to quicker degradation of the tool.

Low Binder Content:

A lower binder content leads to a harder, more wear-resistant material, making it ideal for applications that involve prolonged abrasion and wear.

However, the material may become more brittle and prone to cracking under high-impact conditions.

When choosing the right binder content, it’s essential to balance hardness and toughness based on the demands of the specific task at hand.

Binder Content and Toughness: Improving Impact Resistance

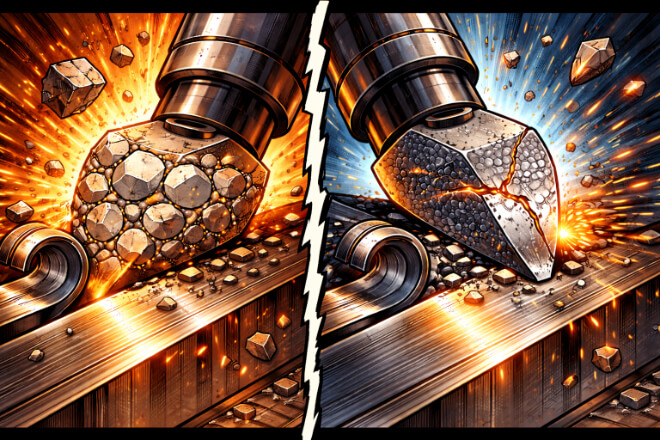

Toughness is the ability of a material to withstand impact and shock without breaking. The binder content in tungsten carbide plays a critical role in determining the material’s dureté.

Higher Binder Content:

Tungsten carbide tips with a higher binder content are more flexible and less likely to crack or shatter under high-impact loads.

This makes them suitable for applications where the tool is exposed to shock, such as in exploitation minière, drilling, and other heavy-duty operations.

Teneur en liant plus faible:

While a lower binder content increases dureté, it also makes the material more brittle.

Tungsten carbide tips with low binder content are more susceptible to cracking or chipping when exposed to high-impact forces, making them unsuitable for applications involving frequent shock or impact.

Therefore, understanding the specific application and expected loading conditions is key to selecting the right binder content for durability and toughness.

Effects of Binder Content on Thermal Conductivity and Heat Resistance

Thermal conductivity and heat resistance are also influenced by the binder content in tungsten carbide.

These properties are essential when the tool is used in high-temperature environments where heat dissipation is necessary to prevent overheating or thermal damage.

High Binder Content:

Materials with a higher binder content typically have lower thermal conductivity compared to materials with lower binder content.

This can be beneficial in high-temperature applications, where maintaining the stability of the material is important. However, the trade-off is a reduction in hardness and résistance à l'usure.

Low Binder Content:

Tungsten carbide with low binder content tends to have better thermal conductivity and heat resistance, which is advantageous when the tool needs to operate at high temperatures.

However, this comes at the cost of toughness and impact resistance.

For high-temperature applications, selecting the appropriate binder content is critical to ensuring that the tungsten carbide tips maintain their integrity while preventing overheating.

Choosing the Right Binder Content for Your Application

Selecting the correct binder content for tungsten carbide tips depends on the specific demands of the application. Here are some factors to consider when making the decision:

Type d'application:

For cutting and machining hard materials that experience heavy wear, a lower binder content may be preferred to increase dureté et wear resistance.

On the other hand, for applications with high-impact forces, such as mining or drilling, higher binder content is needed to enhance dureté and resistance to cracking.

Operating Environment:

If the tungsten carbide tips will be exposed to high temperatures, high binder content may help maintain material stability and prevent thermal damage.

Conversely, in environments with low temperature fluctuations, a lower binder content may be sufficient.

Longevity and Tool Life:

Consider the required tool lifespan. For applications that require long-lasting performance, a balance between binder content, wear resistance, and toughness must be struck to maximize tool life.

By considering these factors, manufacturers can choose the optimal binder content to ensure the durability and performance of tungsten carbide tips in various applications.

Conclusion

Binder content strongly influences the durability of tungsten carbide tips. Low binder improves wear resistance but increases cracking risk.

High binder improves toughness but reduces hardness. The best choice depends on the working environment, not just hardness values.

For decision-makers, understanding binder content leads to longer tool life, fewer failures, and better overall performance.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.