In the world of high-speed machining and precision manufacturing, outils de coupe en carbure de tungstène are the workhorses behind accurate and efficient operations.

These tools are known for their exceptional hardness and resistance to wear. But even the best tool needs a little help to perform at its peak—and that’s where coolant and lubrication come in.

Using the right coolant or lubricant doesn’t just reduce heat. It improves the cutting process, protects the tool, enhances surface finish, and extends tool life.

For decision-makers in machining industries, understanding this relationship is key to cutting costs and boosting productivity.

In this article, we explore how coolant and lubrication affect tungsten carbide cutting tools, and what best practices you should follow to get the most out of them.

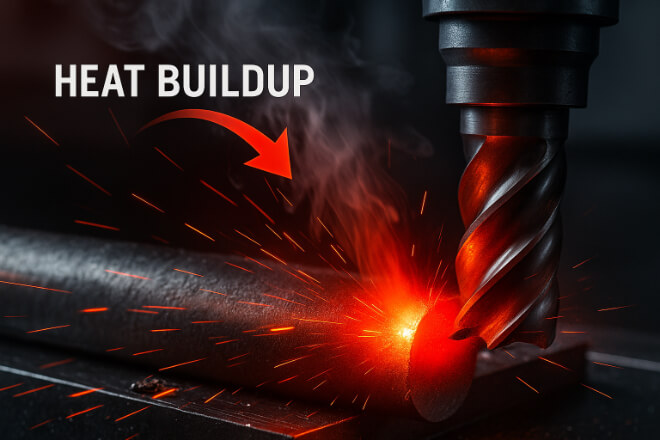

Why Heat Is the Enemy of Cutting Tools

When tungsten carbide tools cut metal, the friction between the tool and the workpiece generates intense heat—especially at high speeds. If this heat is not managed properly, it can lead to:

Premature tool wear

Built-up edge on the cutting surface

Mauvaise finition de surface

Micro-cracking or chipping of the tool

Material welding to the tool

Even though tungsten carbide can withstand more heat than HSS (High-Speed Steel), it still suffers under extreme conditions. That’s why coolant and lubrication are essential.

What Does Coolant Do in Machining?

Coolant is a fluid used during machining to control temperature, flush away chips, and sometimes add lubrication. Common coolants include:

Water-based solutions (soluble oils, semi-synthetics)

Straight oils (cutting oils)

Synthetic fluids

Coolants serve three primary purposes:

Cooling: Reduces the temperature at the cutting zone to prevent thermal damage.

Flushing: Clears chips from the cutting area to prevent recutting.

Lubricating: Reduces friction between tool and material.

By keeping the cutting environment cool and clean, coolant helps carbide tools cut more efficiently and last longer.

Lubrication vs. Coolant: What’s the Difference?

While coolant focuses on temperature and chip removal, lubrication focuses more on friction reduction.

Lubricants may be oils, mists, or solid-based, and are especially useful in operations where:

Surface finish is critical

Tools need to cut sticky or ductile materials (like aluminum or copper)

There’s a risk of built-up edge

High-speed or dry machining is used

In many operations, coolant and lubricant are combined into one solution to offer both heat control and surface protection.

Key Benefits of Using Coolant and Lubricants with Tungsten Carbide Tools

Here’s why proper fluid use is critical for decision-makers aiming for long-term machining efficiency:

1). Reduced Tool Wear

Fluids act as a barrier between the tool and the workpiece, reducing direct friction. This slows down abrasive wear and minimizes micro-cracks in the cutting edge.

2). Longer Tool Life

With better heat control, the tungsten carbide retains its hardness longer. This leads to fewer tool changes and lower replacement costs.

3). Improved Surface Finish

Proper lubrication avoids tearing or smearing of the workpiece material, leading to smoother surfaces.

4). Less Built-Up Edge (BUE)

Coolant and lubricants prevent sticky materials from welding to the tool, which affects part tolerance and surface quality.

5). Better Chip Control

Coolants help in breaking and removing chips effectively, especially in high-speed or deep cuts.

Choosing the Right Coolant or Lubricant for Carbide Tools

Not all fluids are created equal. The choice depends on your material, speed, and process type.

Here’s a quick comparison:

Best Coolant Types by Application

| Application | Matériel | Recommended Fluid |

|---|---|---|

| Fraisage à grande vitesse | Steel, stainless steel | Semi-synthetic coolant |

| Turning & boring | Cast iron, tool steel | Straight cutting oil |

| Finition | Aluminum, brass | Light oil or micro-lubrication (MQL) |

| Hard machining | Titane, Inconel | High-pressure coolant with additives |

Tip: Always check if the fluid is compatible with carbide. Some fluids may promote corrosion if not maintained properly.

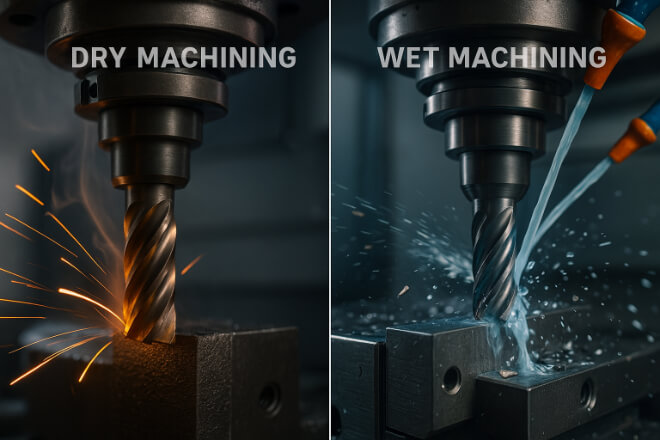

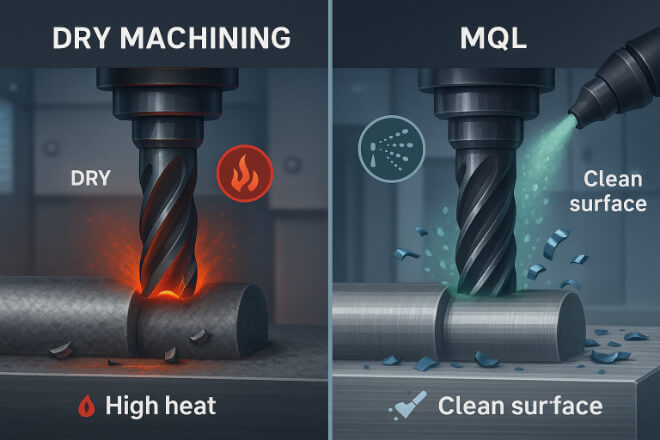

Dry Machining vs. Wet Machining with Tungsten Carbide

Dry machining means no coolant is used—relying only on air or tool coatings to manage heat.

While it works in some operations, it’s not ideal for heavy-duty machining or abrasive materials.

Wet machining with coolant provides more reliability and tool longevity.

Tungsten carbide tools, though heat-resistant, still benefit from coolant when cutting at high speeds or under load.

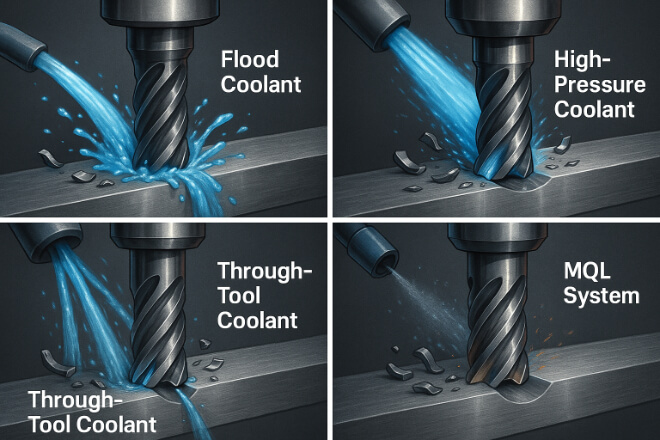

How Coolant Delivery Affects Performance

Even with the right coolant, how it’s delivered matters. There are several methods:

Flood coolant: Covers the cutting area completely. Good for general-purpose operations.

High-pressure coolant: Ideal for deep hole drilling or cutting hard materials.

Through-tool coolant: Coolant flows inside the tool and exits near the cutting edge. Highly efficient.

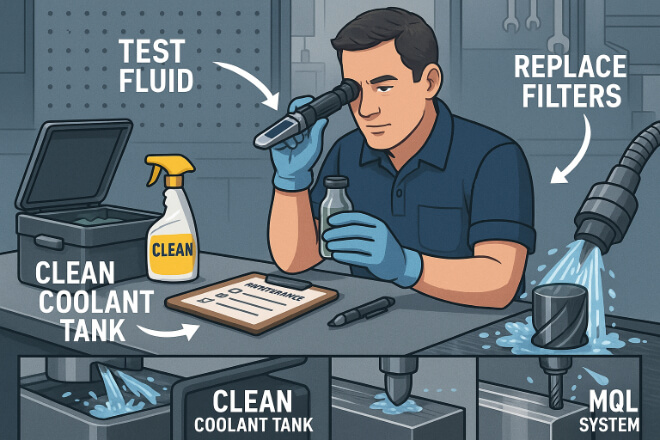

Minimum Quantity Lubrication (MQL): A small mist of lubricant is applied directly. Great for eco-friendly and low-heat applications.

Through-tool coolant is particularly beneficial for carbide drills and end mills in deep cuts or small diameters.

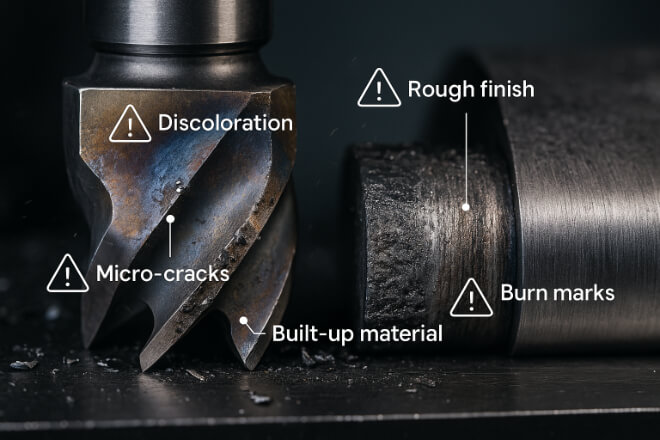

Signs of Poor Coolant/Lubrication Management

If you notice the following, it might be time to rethink your fluid setup:

Burn marks or discoloration on parts

Early tool wear or chipping

Inconsistent surface finish

Buildup of chips or material on the tool

Excessive vibration or chatter during cutting

Coolant isn’t a “set and forget” system. Regular maintenance—checking fluid concentration, pH levels, and chip removal—is key.

Coolant and Lubricant Maintenance Best Practices

To get the full benefits of fluid systems, follow these maintenance tips:

Monitor concentration: Use a refractometer to keep coolant in range.

Clean tanks regularly: Avoid bacterial growth and residue buildup.

Replace filters: Dirty filters block coolant flow.

Check for leaks or pump issues: Poor delivery = poor performance.

If your shop invests in tungsten carbide cutting tools, don’t undermine their performance with poor fluid management.

Coolant Alternatives: When to Consider Dry or MQL

1). Dry machining can be suitable for:

Low-speed applications

Non-ferrous materials

Situations where coolant is too costly or hard to dispose of

2). Minimum Quantity Lubrication (MQL) is ideal when you want:

Cleaner parts

Less environmental impact

Reduced fluid consumption

But for most high-load, high-speed applications, especially with carbide tools, a well-maintained coolant system remains the gold standard.

Réflexions finales

Coolant and lubrication are not just accessories—they are vital partners for your tungsten carbide cutting tools.

The right fluid setup improves tool life, enhances cut quality, prevents heat damage, and keeps your operation running smoothly.

For companies focused on precision, efficiency, and tool ROI, optimizing coolant and lubrication strategies should be part of your core planning.

Don’t let poor fluid management waste your investment in premium cutting tools.

Want to upgrade your cutting tool performance? Explore high-quality tungsten carbide tools at Retopz —backed by technical support and expert advice.