In the machining world, cutting speed is more than just a number—it directly affects productivity, tool life, and part quality.

When using outils de coupe en carbure de tungstène, understanding the correct cutting speed range is key. Get it wrong, and you’ll see problems like overheating, tool wear, or poor surface finish.

Get it right, and you’ll unlock high precision, lower costs, and smooth operations.

In this blog, we break down how cutting speed works with carbide tools, what factors affect it, and what ranges to aim for across different materials.

What Is Cutting Speed?

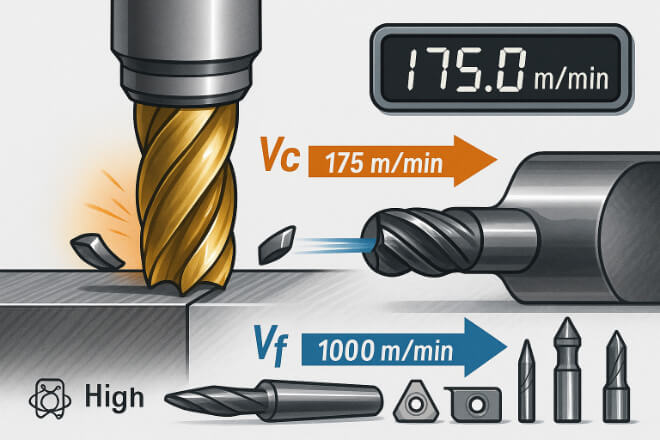

Cutting speed is the speed at which the cutting edge of the tool moves across the material surface. It is usually measured in meters per minute (m/min) or surface feet per minute (SFM).

The faster the cutting speed, the more material the tool can remove in a given time—but also the more heat it generates.

For tungsten carbide tools, cutting speed is generally higher than for high-speed steel tools, thanks to carbide’s excellent heat resistance and dureté.

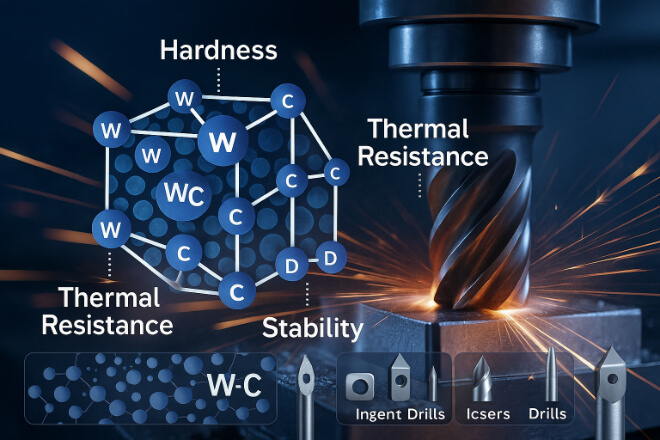

Why Tungsten Carbide Can Handle High Speeds

Tungsten carbide is a super-hard material made by combining tungsten and carbon atoms, often with a cobalt binder. Its unique structure offers:

Haut dureté at elevated temperatures

Fort résistance à l'usure

Good dimensional stability

Low thermal expansion

Because of these features, carbide tools can maintain sharp edges and perform well at high speeds—even under tough machining conditions.

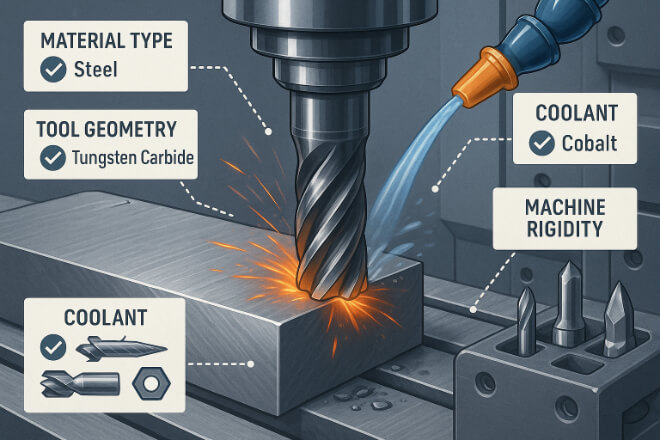

Factors That Affect Cutting Speed

Before jumping into numbers, remember that cutting speed is not fixed. It depends on:

Material of the workpiece: Harder materials require slower speeds.

Tool geometry: Sharp angles and small diameters may need speed adjustments.

Coolant/lubrication: Better cooling often allows higher speeds.

Machine rigidity: More rigid machines can handle faster speeds without vibration.

Type of operation: Roughing vs finishing passes have different needs.

Tool coating: Coated tools like TiAlN or CVD diamond resist heat better, supporting higher speeds.

Recommended Cutting Speeds by Material

Here’s a simplified table showing typical cutting speed ranges for carbide tools across common materials.

| Type de matériau | Cutting Speed (m/min) | Remarques |

|---|---|---|

| Mild Steel | 100 – 250 | Dry or with light coolant |

| Acier inoxydable | 60 – 150 | Use coated tools for best results |

| Fonte | 80 – 200 | Gray cast iron handles dry cutting well |

| Aluminium | 200 – 600 | High speed with sharp tools |

| Titanium Alloys | 30 – 60 | Use plenty of coolant |

| Hardened Steel (45-60 HRC) | 30 – 80 | Requires special carbide grades |

| Brass/Bronze | 100 – 300 | Low risk of built-up edge |

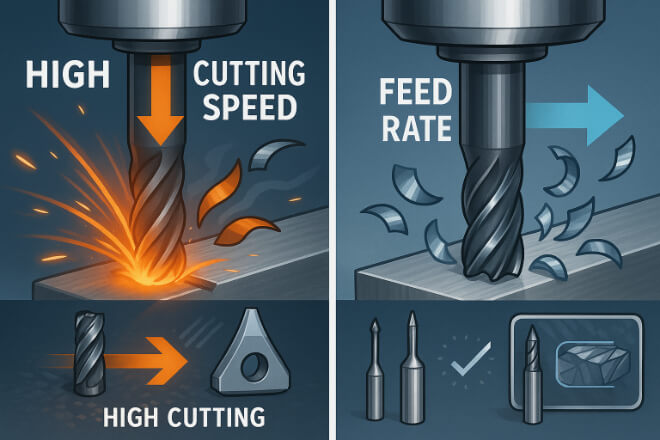

Cutting Speed vs Feed Rate: Don’t Mix Them Up

While cutting speed measures how fast the cutting edge moves, feed rate is how much the tool advances per revolution or per minute.

Higher cutting speeds = Faster material removal, more heat

Higher feed rates = Thicker chips, more tool pressure

To avoid problems like tool breakage or chatter, you need the right balance between speed and feed.

Start in the mid-range, and adjust based on tool wear, finish quality, and machine sound.

Common Problems from Wrong Cutting Speeds

Choosing the wrong speed can hurt your tool and your part. Here are a few issues that can happen:

| Problème | Caused By |

|---|---|

| Burnt tool edge | Too high speed, no coolant |

| Bord rapporté (BUE) | Too low speed, soft materials |

| Chatter or vibration | Speed-feed mismatch |

| Short tool life | Poor speed control |

| Rough surface finish | Speed too low or unstable |

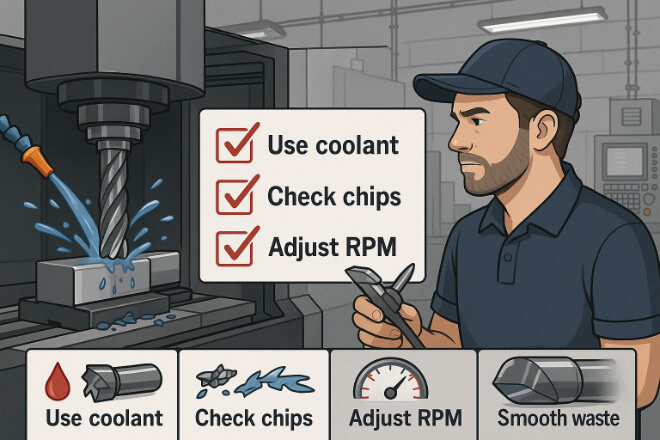

Tips to Optimize Cutting Speed for Carbide Tools

Want smoother, faster, and longer-lasting results? Try these tips:

Always follow manufacturer’s speed guidelines

Use coated carbide tools for tough materials

Keep your machine rigid and well-maintained

Use proper coolant or misting where needed

Do trial cuts and fine-tune based on chip color and finish

Pro tip: Bright silver or blue chips usually indicate a good cut. Dull or burnt chips mean trouble.

High-Speed Machining (HSM) with Carbide

Tungsten carbide tools are perfect for High-Speed Machining (HSM). This technique uses high spindle speeds and light cutting loads to increase efficiency.

Benefits of HSM with carbide tools include:

Des temps de cycle plus rapides

Lower cutting forces

Reduced thermal deformation

Better finishes and tighter tolerances

However, HSM only works if your tool, material, and machine are compatible. You may need dynamic balancing and vibration control.

Using Coated Carbide Tools at High Speeds

Coatings make a huge difference in high-speed cutting. They:

Reduce friction

Act as thermal barriers

Prolonger la durée de vie de l'outil

Popular coatings for high-speed carbide cutting:

| Type de revêtement | Idéal pour | Avantage |

|---|---|---|

| TiAlN | Steel, Inconel | Haute résistance à la chaleur |

| DLC | Aluminum, copper | Anti-stick, low friction |

| Diamant CVD | Graphite, composites | Extreme wear resistance |

Tool Diameter and Speed – What You Should Know

Smaller tools need higher RPMs to reach the same surface speed. Here’s a quick cheat sheet:

| Tool Diameter (mm) | Speed (RPM) @ 100 m/min |

|---|---|

| 5 mm | 6360 |

| 10 mm | 3180 |

| 20 mm | 1590 |

| 40 mm | 795 |

Use this rule: Bigger tool = lower RPM for the same cutting speed.

Réflexions finales

Tungsten carbide tools are made for high-performance cutting—but only if they’re used the right way.

Getting the cutting speed right is one of the simplest and most powerful ways to boost your machining results.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.