bagues en carbure de tungstène are highly valued for their durability, résistance à l'usure, et dureté, making them ideal for use in demanding applications like pumps, machinery, and aérospatial composants.

However, to ensure optimal performance and lifespan, the surface finish of the bushings plays a crucial role.

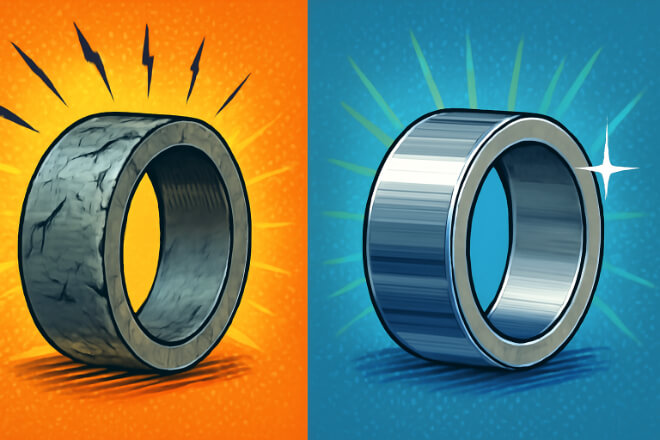

Two key processes that significantly impact the performance of tungsten carbide bushings are polishing and lapping.

In this blog, we will explore the role of polishing and lapping in enhancing the performance of tungsten carbide bushings, focusing on their effects on friction, wear resistance, and overall efficiency.

What is Polishing?

Polishing is a process that involves smoothing the surface of a material to a high shine.

In the context of tungsten carbide bushings, polishing is typically done after the initial grinding process to achieve a smooth, uniform finish.

The goal of polishing is to reduce surface roughness, which helps decrease friction and improve the bushing’s performance.

1). Polishing Process for Tungsten Carbide Bushings:

Abrasive Materials: Polishing is done using fine abrasive materials, such as diamond powder or silicon carbide. These abrasives are used to gradually smooth the surface of the bushing.

Techniques: The bushing is usually mounted on a rotating surface or platen where the polishing material is applied. This technique ensures an even surface finish without causing surface defects.

Surface Finish (Ra Value): The Ra value (arithmetic average roughness) typically achieved during polishing for tungsten carbide bushings is between Ra 0.05 to 0.2 µm. This smooth surface minimizes friction between the bushing and the shaft.

2). Benefits of Polishing for Tungsten Carbide Bushings:

Friction Reduction: Polishing creates a smoother surface, which reduces friction between the bushing and the shaft. This leads to less heat generation and improved overall efficiency.

Amélioré Résistance à l'usure: A smoother surface reduces the chances of wear and tear, as there are fewer asperities (rough spots) that can cause material degradation.

Enhanced Performance: With reduced friction and wear, polished tungsten carbide bushings provide longer-lasting and more reliable performance in various industrial applications.

What is Lapping?

Lapping is a more precise and finer finishing process than polishing. It involves the use of an abrasive slurry and a flat surface to achieve an ultra-smooth finish.

Lapping is typically used after polishing to achieve the final, high-precision surface needed for high-performance bushings.

1). Lapping Process for Tungsten Carbide Bushings:

Abrasive Slurry: The lapping process uses a slurry composed of fine abrasives suspended in a liquid. This slurry is applied to the bushing’s surface to remove any remaining surface imperfections.

Rotating Plate: The tungsten carbide bushing is placed on a rotating lapping plate. The abrasive slurry works to gradually remove material from the surface, leaving behind a mirror-like finish.

Ra Value: The Ra value achieved by lapping is typically much finer than polishing, often reaching Ra values of 0.01 µm or less, resulting in a highly smooth and low-friction surface.

2). Benefits of Lapping for Tungsten Carbide Bushings:

Ultra-Smooth Surface: Lapping provides a smoother surface than polishing alone, making it ideal for applications that demand minimal friction and wear, such as in precision machinery and high-speed pumps.

Precision and Accuracy: Lapping ensures precise dimensional control, making it essential for applications where tight tolerances are required.

Increased Durability: A lapped surface reduces the likelihood of stress concentration points, which can lead to cracks or premature failure under heavy load or high-speed conditions.

Polishing vs. Lapping: Which is Better for Tungsten Carbide Bushings?

While both polishing and lapping improve the surface finish of tungsten carbide bushings, each process offers unique benefits depending on the application. Here’s a comparison of the two:

| Fonctionnalité | Polissage | Lapping |

|---|---|---|

| Finition de surface | Ra 0.05 – 0.2 µm | Ra < 0.01 µm |

| Précision | Moderate precision | High precision and accuracy |

| Friction Reduction | Reduces friction and wear | Further reduces friction for minimal wear |

| Applications | High-speed machinery, general wear resistance | Precision machinery, high-performance bearings |

| Process | Easier to perform, less time-consuming | More time-consuming, requires specialized equipment |

| Avantages | Increased efficiency, better wear resistance | Ultra-smooth finish, longer lifespan, high precision |

1). When to Use Polishing:

Polishing is ideal for applications where moderate precision is sufficient, such as in high-speed pumps and motors. It’s also a quicker process and less costly than lapping.

2). When to Use Lapping:

Lapping is necessary for applications requiring high precision and ultra-smooth finishes, such as in aérospatial components or precision machinery where minimal friction and high reliability are crucial.

How Polishing and Lapping Extend the Lifespan of Tungsten Carbide Bushings

The combination of polishing and lapping creates a bushing surface that minimizes friction, reduces heat generation, and prevents wear.

These improvements significantly extend the lifespan of tungsten carbide bushings. Here’s how:

Reduced Friction: Both polishing and lapping reduce surface roughness, which lowers friction between the bushing and the shaft. This reduces heat and wear, which is critical for maintaining the performance of the bushing over time.

Amélioré Résistance à l'usure: Smoother surfaces result in less abrasive contact, preventing material degradation. As a result, the tungsten carbide bushing lasts longer in high-speed or high-load applications.

Enhanced Load Distribution: With a smoother surface, load is distributed more evenly across the bushing, preventing localized wear and extending its life in demanding applications.

Surface Finish Comparison for Polishing and Lapping

| Process | Ra Value (µm) | Application | Avantages |

|---|---|---|---|

| Polissage | Ra 0.05 – 0.2 µm | High-speed machinery, pumps | Reduces friction, improves wear resistance |

| Lapping | Ra < 0.01 µm | Precision machinery, high-speed bearings | Ultra-smooth finish, high precision |

Conclusion

Polishing and lapping are essential processes that significantly enhance the performance and lifespan of tungsten carbide bushings.

By reducing friction, improving wear resistance, and ensuring high precision, these processes make tungsten carbide bushings suitable for a wide range of demanding applications.

Understanding when to apply polishing versus lapping can help manufacturers optimize the performance of their bushings and maximize their operational efficiency.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.