Tungsten carbide balls are small in size, but they deliver big value in many industrial sectors.

Known for their extreme dureté, high résistance à l'usure, and ability to work under heavy loads, they are chosen over steel balls when performance and reliability are critical.

For decision-makers, understanding where these balls are used can help plan better investments and reduce long-term costs.

This article explains the top applications of tungsten carbide balls in industry, showing how they support bearings, vannes, ball screws, grinding operations, pétrole et gaz tools, and precision instruments.

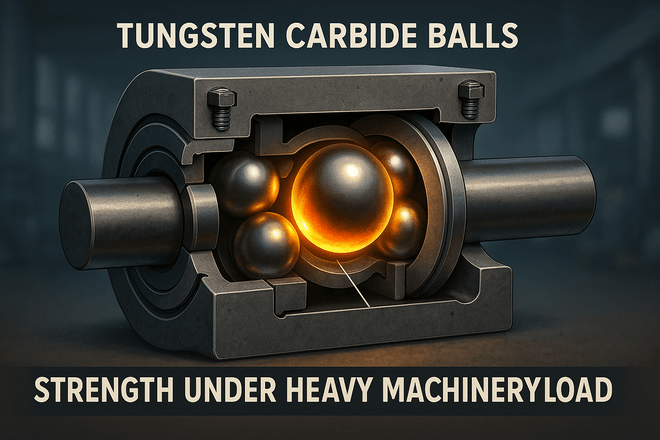

Bearings for Heavy Loads and Long Life

One of the largest uses of tungsten carbide balls is in bearings.

Bearings with carbide balls are used in heavy machinery, aérospatial, et automobile systems.

À cause de leur dureté and ability to handle stress, these balls:

Last longer than steel bearings

Reduce friction under high pressure

Keep machines running smoothly even in tough conditions

For industries where downtime is costly, carbide ball bearings are a smart investment.

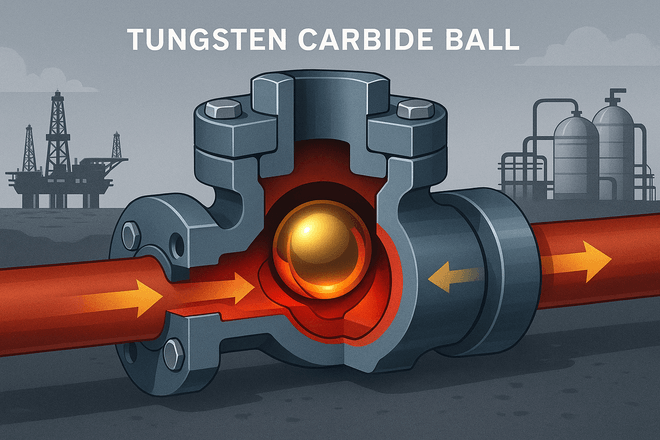

Valves in Oil, Gas, and Chemical Sectors

Tungsten carbide balls play a key role in industrial valves. In pétrole et gaz pipelines, chemical plants, and power generation, valves must seal tightly to avoid leaks.

Steel balls often wear down quickly, but carbide balls resist:

Abrasion from sand, slurry, and fluids

Corrosion due aux produits chimiques et à l'eau de mer

High pressure from pipelines and drilling operations

This makes them vital for reducing maintenance and improving safety.

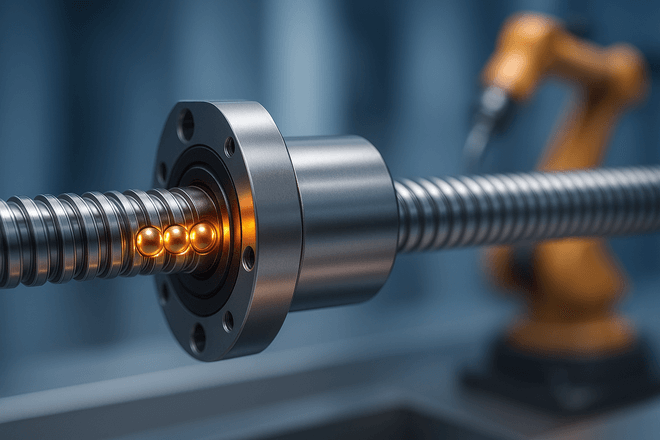

Ball Screws in CNC Machines and Robotics

Precision equipment like CNC machines and robotic systems rely on ball screws for accurate movement. Tungsten carbide balls in ball screws provide:

High accuracy and smooth travel

Less wear during continuous operation

Longer service life compared to steel

For manufacturers in aérospatial, médical devices, and automotive sectors, carbide ball screws mean better precision and higher productivity.

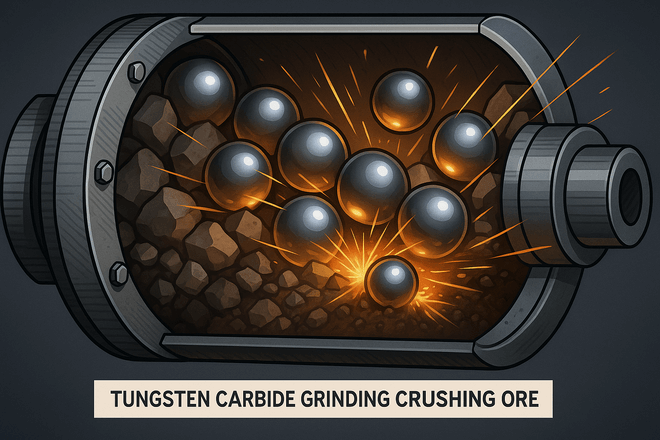

Grinding and Milling Media

Tungsten carbide balls are widely used as grinding and milling media.

They are placed inside ball mills to crush hard materials like minerals, alloys, and ceramics.

Compared to steel balls, they:

Provide finer grinding results

Last longer before replacement

Reduce contamination of processed materials

Mining, cement, and chemical industries depend on carbide grinding media for efficiency and cost savings.

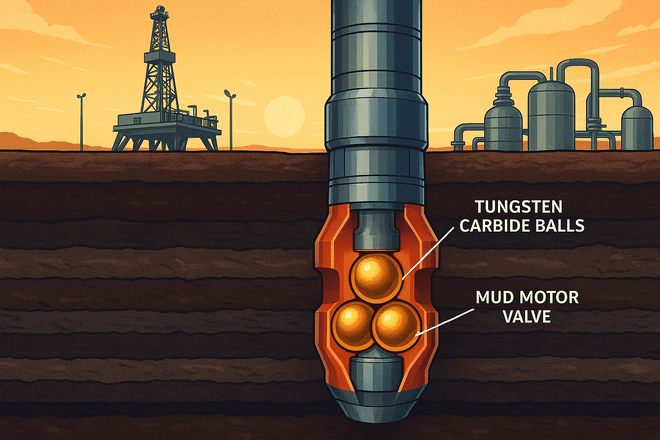

Oil & Gas Drilling Tools

In the oil and gas sector, carbide balls are used in drilling tools and downhole equipment.

These tools must survive extreme conditions such as high heat, pressure, and abrasive fluids. Tungsten carbide balls:

Improve tool reliability in deep drilling

Reduce wear in mud motors and drilling valves

Extend the life of high-cost oilfield equipment

For oil companies, this directly translates into fewer failures and reduced downtime.

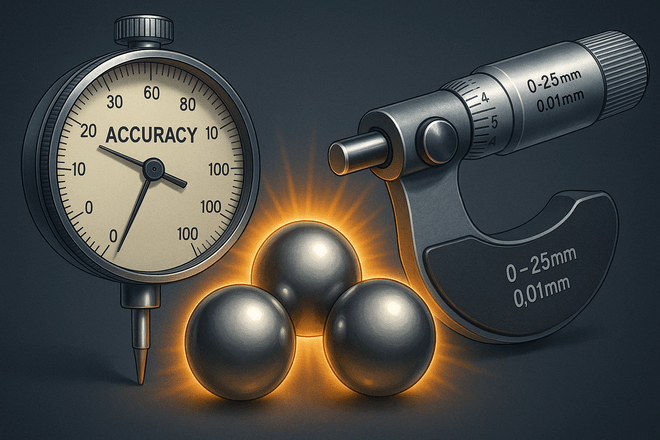

Precision Instruments and Measurement Devices

Carbide balls are also used in precision instruments such as gauges, measuring tools, and medical devices.

Their extreme hardness allows them to hold shape and accuracy for a very long time. Benefits include:

Stable calibration over time

Resistance to deformation

High accuracy in critical measurements

This makes them ideal for industries where precision cannot be compromised.

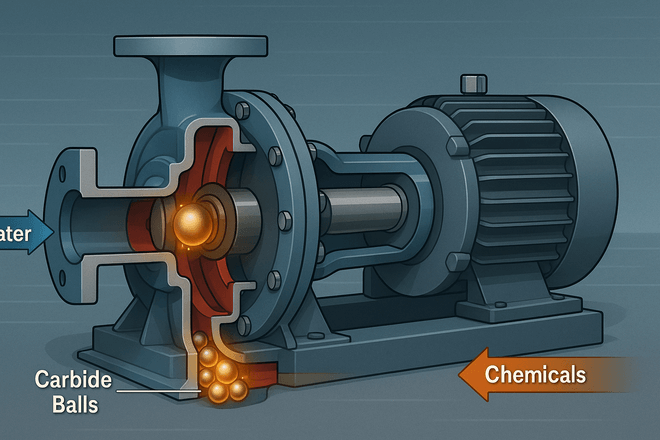

Pumps and Sealing Systems

In industrial pumps and sealing systems, tungsten carbide balls help reduce leaks and withstand friction.

They resist erosion from abrasive liquids and maintain smooth performance under continuous operation.

This application is common in water treatment, petrochemicals, and food processing industries.

Comparison Table: Tungsten Carbide Balls vs Steel Balls

| Fonctionnalité | Billes en carbure de tungstène | Billes d'acier |

|---|---|---|

| Dureté | Very high (90+ HRA) | Moderate (~60 HRC) |

| Résistance à l'usure | Excellent, long service life | Lower, wears faster |

| Résistance à la corrosion | Strong against chemicals and seawater | Weak against corrosives |

| Applications | Bearings, valves, flowmeters, oil & gas | General machinery |

| Coût | Plus élevé à l'avance | Plus bas à l'avant |

Réflexions finales

Tungsten carbide balls are critical components across many industries.

From bearings in heavy machinery to valves in oil & gas, and from ball screws in CNC systems to grinding media in mining, their applications are broad and essential.

For decision-makers, the message is clear: although carbide balls cost more upfront, they deliver longer life, better performance, and lower long-term costs.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.