In many industries, from bearings and valves to milling media and aérospatial components, balls made from different materials are used to handle load, friction, and wear.

Among the options, billes de carbure de tungstène and steel balls are the most common.

At first glance, they may look similar, but their performance is very different. Choosing between them depends on your application, cost targets, and long-term goals.

In this article, we will compare tungsten carbide balls vs steel balls in terms of dureté, densité, résistance à l'usure, cost, and applications.

For decision-makers, this comparison helps in making the right investment in material that matches performance needs.

Dureté et résistance à l'usure

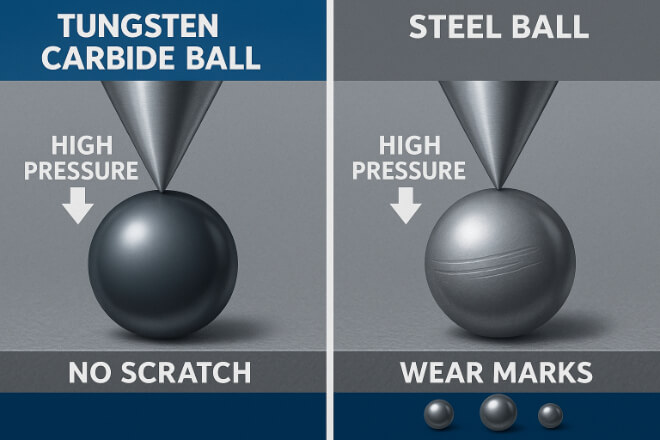

The first big difference is dureté. Tungsten carbide balls are among the hardest industrial materials available, reaching up to 90 HRA on the Rockwell scale.

This hardness allows them to resist surface wear, deformation, and scratches even under extreme loads.

Steel balls, depending on the grade (carbon steel, stainless steel, or chrome steel), are much softer.

Their hardness usually ranges from 55–66 HRC. While good for general use, they wear faster when exposed to high-friction or abrasive environments.

For industries like exploitation minière, pétrole et gaz, and milling, the superior wear resistance of tungsten carbide provides longer life and reduced downtime.

Densité et poids

Tungsten carbide has a density of 14.5–15.1 g/cm³, which is more than double that of steel at around 7.8 g/cm³.

This means a tungsten carbide ball feels significantly heavier than a steel ball of the same size.

The high density gives carbide balls more impact energy and better stability in applications like grinding media and precision bearings.

Steel balls, being lighter, are easier to handle but may lack the same stability in high-stress environments.

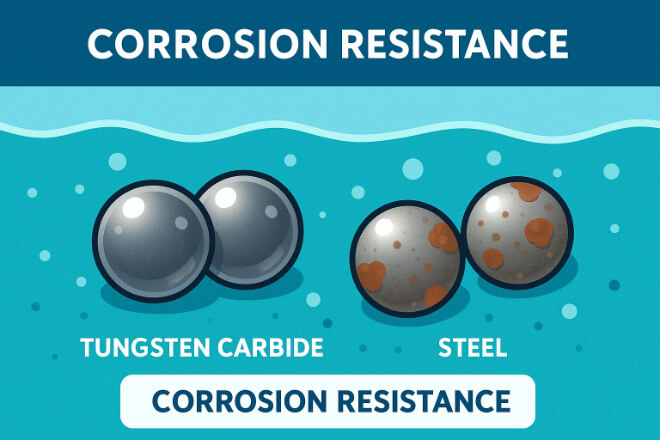

Résistance à la corrosion

Steel is more prone to corrosion, especially in harsh environments with moisture, chemicals, or salt. Stainless steel balls perform better but still degrade over time.

Tungsten carbide balls, on the other hand, show high resistance to corrosion and chemical attack, especially when combined with protective coatings.

This makes them suitable for chemical pumps, valves, and seal applications where exposure to aggressive fluids is unavoidable.

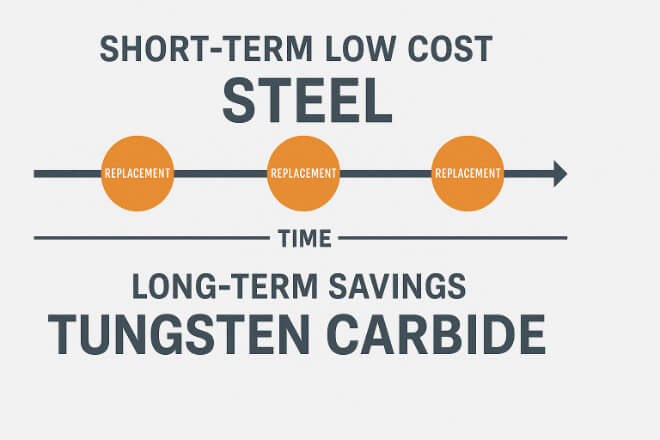

Cost vs Value

Steel balls are much cheaper to produce and buy. For non-critical applications like consumer goods or low-load machinery, steel remains a cost-effective option.

Tungsten carbide balls, while more expensive, deliver better long-term value. They last longer, reduce replacement frequency, and minimize downtime.

For decision-makers calculating cost-per-hour or cost-per-part, carbide often proves more economical over the equipment lifecycle.

Applications typiques

Here is a comparison of where each material is commonly used:

| Matériel | Key Properties | Common Applications |

|---|---|---|

| Billes en carbure de tungstène | High hardness, high density, strong wear and corrosion resistance | Valves, bearings, grinding media, oil & gas tools, aerospace components |

| Billes d'acier | Moderate hardness, lower density, less resistant to wear and corrosion | Automotive bearings, low-load machinery, consumer products |

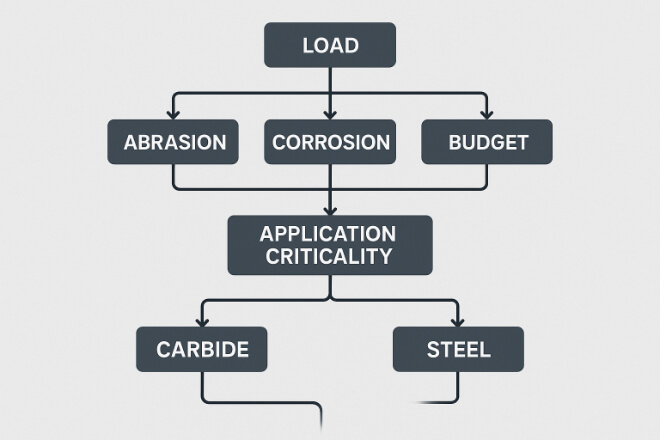

Decision Factors for Choosing

When deciding between tungsten carbide balls and steel balls, consider the following factors:

Load and stress level: High stress favors carbide.

Exposure to abrasion: Carbide lasts longer in abrasive environments.

Corrosion environment: Carbide with coatings outperforms steel.

Budget: Steel is cheaper up front but carbide saves cost over time.

Application criticality: For safety-critical systems, carbide is usually the safer choice.

Conclusion

The debate of tungsten carbide vs steel balls is not about which material is universally better—it’s about which is right for your application.

If you need low cost, moderate performance, steel balls are sufficient.

If you need maximum durability, wear resistance, and long-term value, tungsten carbide is the clear winner.

For decision-makers in heavy industries, the choice often comes down to balancing initial cost vs lifetime value. And in many cases, tungsten carbide proves to be the smarter investment.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.