In modern industrial equipment, precision and reliability depend heavily on materials that can handle extreme wear, pressure, and temperature.

One such material is tungsten carbide, and one of its most important applications is in bushings.

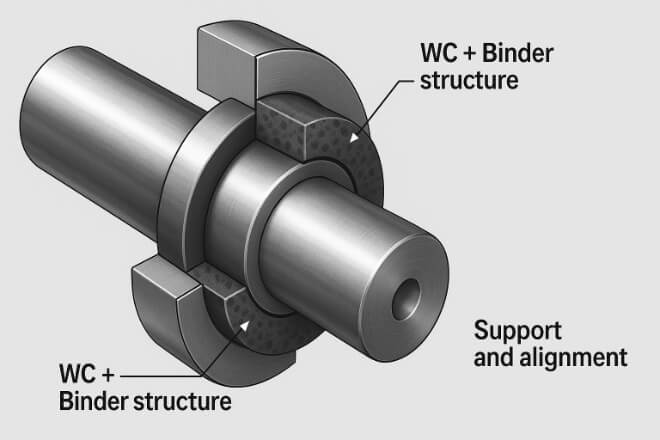

bagues en carbure de tungstène play a key role in supporting rotating shafts, reducing friction, and extending the life of pumps, compressors, turbines, and other machines.

Their secret lies in their unique structure, composition, and micrograin design — each engineered for specific performance goals.

This article breaks down how tungsten carbide bushings are structured, what they’re made of, and how micrograin size affects their dureté, dureté, et la durée de vie.

What Is a Tungsten Carbide Bushing?

A tungsten carbide bushing is a ring-shaped component made by combining poudre de carbure de tungstène (WC) with a metallic binder such as cobalt (Co) or nickel (Ni).

These two materials are blended, pressed, and sintered at high temperature to form a dense, extremely hard solid.

The result is a component that resists wear, corrosion, and deformation under high loads.

In many industries, tungsten carbide bushings are used in:

Pump and compressor shafts

Hydraulic systems

Oilfield drilling tools

Chemical and marine equipment

Their structure gives them superior strength and durability compared with steel or bronze bushings.

Structural Composition of Tungsten Carbide Bushings

| Composant | Matériel | Main Function |

|---|---|---|

| Hard Phase | Tungsten Carbide (WC) | Provides hardness and wear resistance |

| Binder Phase | Cobalt (Co) or Nickel (Ni) | Adds toughness and metallic bonding |

| Porosité | Controlled microvoids | Helps with lubrication and stress absorption |

The hard WC phase gives the material its incredible résistance à l'usure, while the metal binder provides dureté and flexibility.

This two-phase structure acts like concrete reinforced with steel — hard but not brittle.

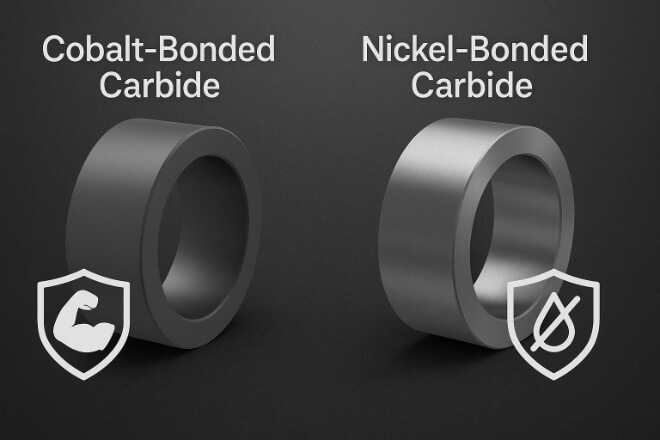

Role of the Binder Metal

The binder is crucial because it connects WC grains and affects how the bushing behaves under load and temperature.

Cobalt (Co): Offers superior dureté and shock resistance; best for mechanical and abrasive environments.

Nickel (Ni): Provides high résistance à la corrosion; ideal for seawater, acids, and chemical exposure.

Dual binders (Co + Ni): Combine both advantages for special-purpose bushings.

Binder Metal Comparison

| Type de liant | Avantages | Application typique |

|---|---|---|

| Cobalt (Co) | High strength and shock resistance | General-purpose pumps, compressors |

| Nickel (Ni) | Excellente résistance à la corrosion | Chemical and marine equipment |

| Cobalt + Nickel | Balanced corrosion and strength performance | Harsh multiphase environments |

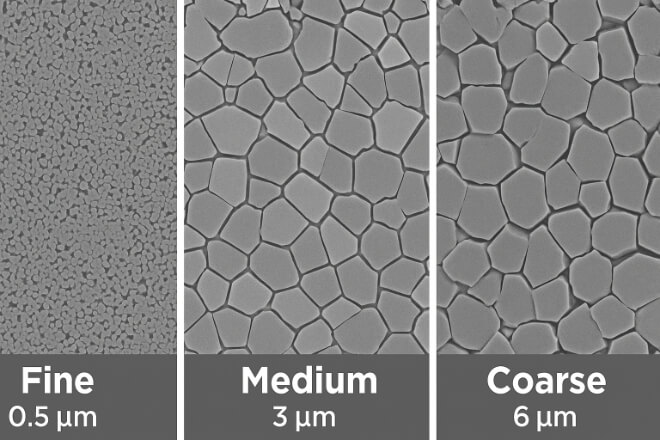

Understanding Micrograin Types

The grain size of poudre de carbure de tungstène directly affects the final bushing’s mechanical properties.

Smaller grains increase hardness and surface polish, while larger grains improve dureté.

Manufacturers choose different micrograin grades depending on operating conditions, speed, and environment.

Typical Micrograin Categories

| Micrograin Type | Grain Size (µm) | Propriétés | Recommended Use |

|---|---|---|---|

| Fine-grain | 0.5–1.0 | High hardness, mirror finish | High-speed pumps, precision seals |

| Medium-grain | 1.0–3.0 | Balanced wear and toughness | Compressors, turbines |

| Coarse-grain | 3.0–6.0 | Excellent impact toughness | Slurry, mining, and dredging pumps |

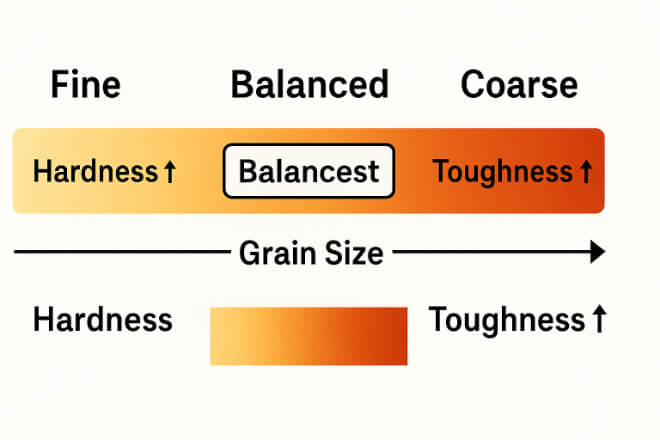

Microstructure and Performance Relationship

The microstructure of tungsten carbide bushings — the arrangement of grains and binders — determines how the material behaves under load.

Fine-grain WC provides high wear resistance and a very smooth surface finish, ideal for tight sealing and low friction.

Medium-grain WC balances strength and wear life for general industrial use.

Coarse-grain WC absorbs shock loads better and resists cracking in aggressive, particle-rich environments.

This balance between grain size and binder content is what gives tungsten carbide its reputation for long-term reliability.

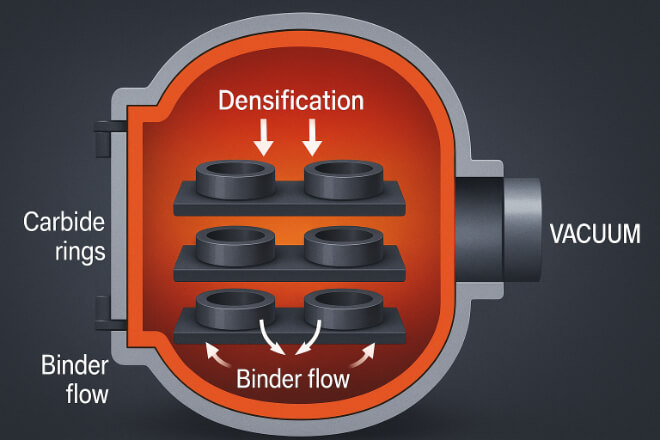

Sintering and Densification

Once the powders are pressed into green shapes, they are sintered in a vacuum furnace at 1350–1500°C.

During this process:

The binder melts and fills the gaps between WC grains.

Porosité decreases dramatically.

The material achieves over 99% theoretical density.

This high density ensures consistent strength and prevents fluid leakage in dynamic applications like seals and pumps.

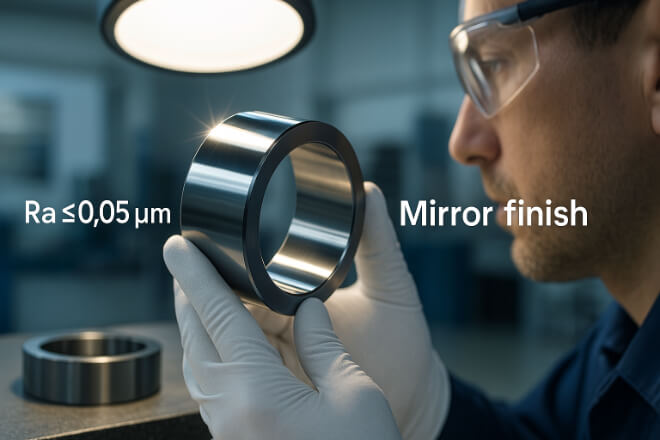

Visual and Surface Finishing

After sintering, bushings undergo several finishing steps — grinding, lapping, and polishing — to achieve smoothness and flatness.

A polished carbide bushing may reach Ra ≤ 0.05 µm, essential for low-friction performance.

Finishing also reveals the quality of the microstructure. A uniform, defect-free surface indicates proper sintering and grain distribution.

Selecting the Right Micrograin for Your Application

| Application | Operating Condition | Suggested Micrograin Type | Type de liant |

|---|---|---|---|

| Clean water pumps | Low abrasiveness, high speed | Fine-grain WC | Co 6% |

| Slurry handling | High particle impact | Coarse-grain WC | Co 12% |

| Seawater and chemicals | Corrosive fluids | Fine-grain WC | Ni 8% |

Selecting the correct combination of micrograin and binder ensures the best performance, balancing wear life, strength, and résistance à la corrosion for each environment.

Conclusion

The performance of a tungsten carbide bushing depends not just on the raw material, but also on how that material is structured at the microscopic level.

Understanding the relationship between structure, composition, and micrograin size helps engineers choose the best grade for their specific application.

With the right design, tungsten carbide bushings deliver exceptional durability, precision, and efficiency, even in the toughest environments.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.