Introduction

In the aerospace industry, every part matters. Aircraft components must meet strict tolerances, high strength requirements, and tight deadlines. To achieve this, manufacturers rely on advanced cutting tools that deliver speed, accuracy, and durability.

One of the most important tools in this process is the tungsten carbide cutting tool. In this article, we explain why tungsten carbide is the material of choice for aerospace machining, what benefits it offers, and how it helps companies meet production and performance goals.

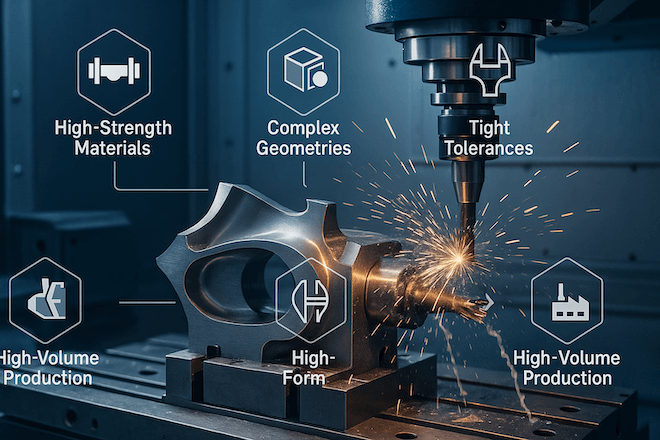

Why Aerospace Machining Needs Advanced Tools

Machining aerospace components is extremely demanding. Key challenges include:

Hard-to-machine materials like titanium, Inconel, and high-strength alloys

Complex shapes such as turbine blades, engine parts, and airframe brackets

Strict tolerances down to microns

Lightweight but strong parts that need precision

High-volume or long-run production under tight schedules

These challenges make it essential to use cutting tools that are tough, precise, and long-lasting.

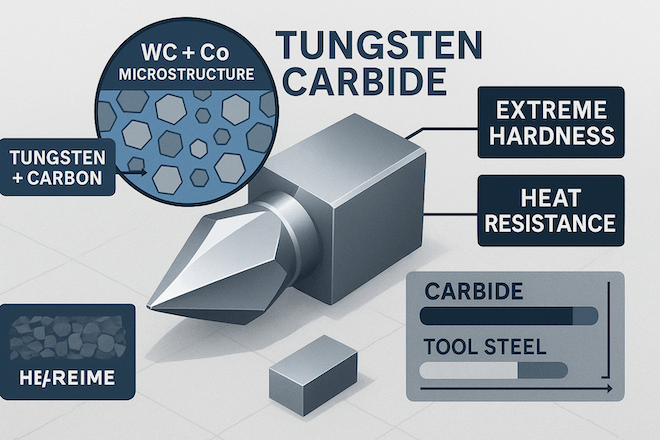

Qu'est-ce que le carbure de tungstène ?

Tungsten carbide is a compound made from tungsten (W) and carbon (C). It is:

Extremely hard—second only to diamond

Très résistant à l'usure

Heat-tolerant, even at high speeds

Stronger and more durable than traditional tool steel

These properties make it ideal for cutting tough aerospace metals.

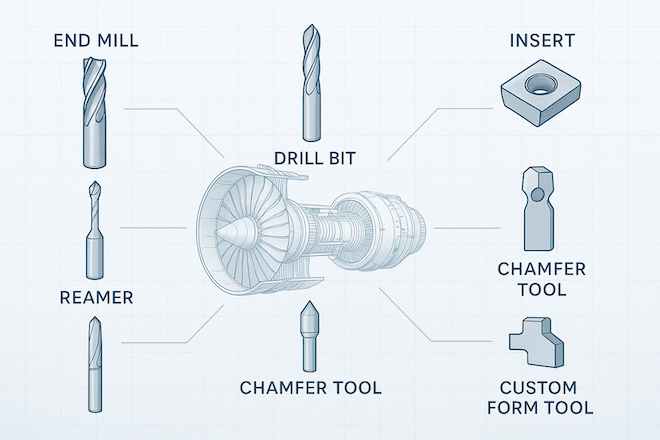

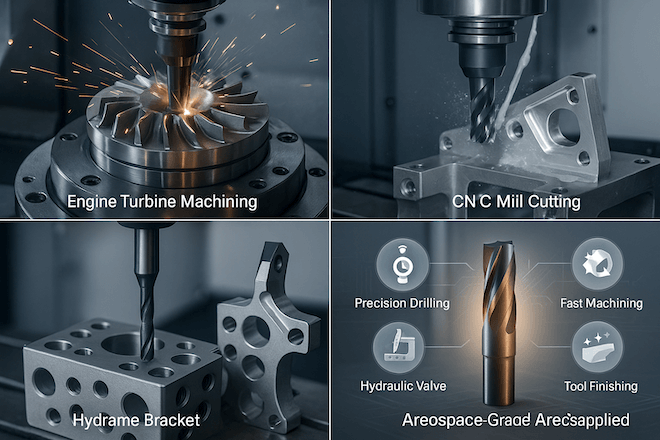

Types of Tungsten Carbide Cutting Tools for Aerospace

Aérospatial manufacturers use a wide range of outils de coupe en carbure, y compris:

Fraises en carbure: For slotting, profiling, and roughing of airframe and engine parts

Forets en carbure: For precise holes in titanium or composites

Plaquettes en carbure: Replaceable tips used in CNC turning and milling operations

Alésoirs en carbure: For smooth finishing of holes

Outils en carbure personnalisés: Tailored to specific aircraft parts or operations

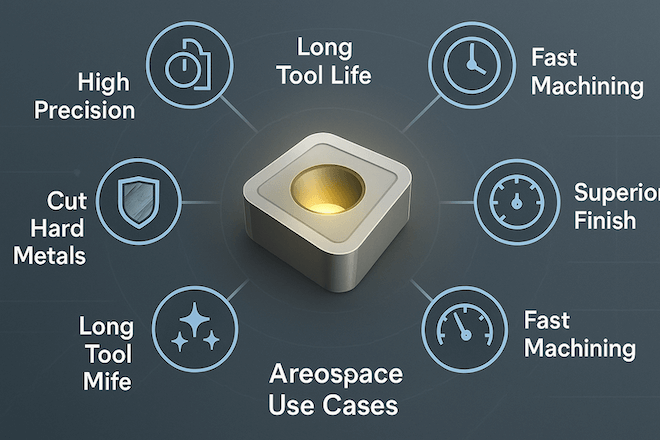

Benefits of Tungsten Carbide Tools in Aerospace

1. High Precision for Critical Parts

Carbide tools can maintain tight tolerances and sharp cutting edges, which is essential for aerospace components like:

Turbine engine blades

Landing gear shafts

Fuel system components

Structural brackets

These parts must function under extreme stress and temperature variations, and require perfect machining.

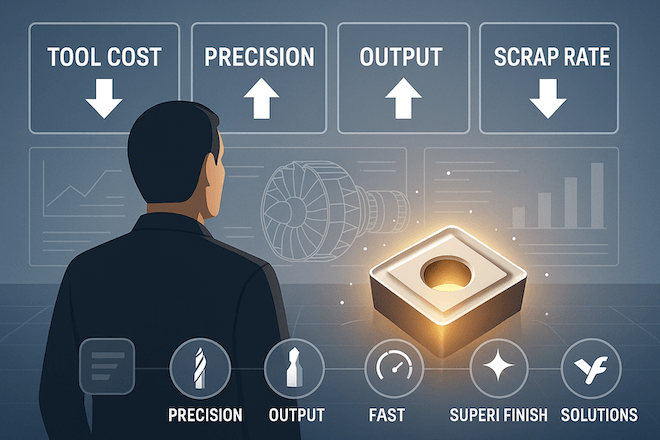

2. Long Tool Life = Lower Cost

Carbide tools last much longer than traditional HSS (high-speed steel) tools. Longer life means:

Moins de changements d'outils

Moins de temps d'arrêt

Des coûts de maintenance réduits

More parts per tool

This is a key factor in reducing total cost per part, especially in large production runs.

3. Excellent Performance on Aerospace Materials

Aerospace machining often involves:

Titanium alloys

Nickel-based superalloys

Carbon fiber composites

Heat-resistant steels

These materials are hard to cut. Tungsten carbide tools maintain performance under high loads, heat, and wear, giving smoother finishes and fewer tool failures.

4. Faster Machining = Greater Output

Carbide tools support high-speed cutting, which helps manufacturers:

Increase cycle time

Improve throughput

Meet tight delivery deadlines

Faster cuts also reduce machine wear and energy consumption.

5. Improved Surface Finish and Part Quality

Aerospace parts often require polished surfaces to improve:

Aerodynamics

Fit and assembly

Fatigue resistance

Carbide tools produce better surface finishes, reducing the need for secondary polishing or rework.

Aerospace Use Cases: Where Carbide Tools Are Applied

| Domaine d'application | Composants typiques | Tool Type Used |

|---|---|---|

| Engines & Turbines | Blades, nozzles, disks | Carbide end mills, drills, reamers |

| Airframes & Structures | Brackets, spars, ribs | Carbide inserts, roughing mills |

| Landing Gear | Shafts, bushings, bearings | Outils en carbure sur mesure |

| Fuel & Hydraulic Systems | Housings, valves, precision bores | Carbide drills, reamers |

| Avionics & Interiors | Panels, mounting parts | Outils en micro carbure |

Why Aerospace Decision Makers Choose Tungsten Carbide

As a manager or engineer in aerospace manufacturing, your priorities include:

Quality assurance

Cost control

Tool inventory planning

Production uptime

Objectifs de durabilité

Using tungsten carbide tools helps you address all of these.

👉 Leading manufacturers are now switching to high-performance carbide tools to improve reliability and gain a competitive edge.

Tips for Aerospace Shops Using Carbide Tools

Choose the right grade for your material (e.g., fine grain for titanium)

Use coated carbide tools (e.g., TiAlN or diamond coatings) for longer life

Monitor tool wear using smart sensors or IoT systems

Apply correct feeds and speeds to avoid tool breakage

Partner with a trusted supplier for technical support and customization

Working with Retop: Your Aerospace Carbide Tool Partner

At Retop, we have over 14 years of experience in producing high-quality tungsten carbide cutting tools. We support the aerospace industry by offering:

Precision carbide inserts

Custom-made cutting tools

Advanced coatings for aerospace materials

Technical support and tool selection guidance

Fast delivery for global clients

👉 Learn more at www.retopz.com

We work with aerospace clients around the world to help them improve tool life, part accuracy, and machining efficiency.

Conclusion

In aerospace component machining, there is no room for error. Every cut must be clean, every part must be precise, and every tool must perform. That’s why more companies are choosing tungsten carbide cutting tools to stay ahead.

Whether you’re machining titanium fan blades or structural aluminum parts, carbide tools offer the strength, speed, and reliability your operations demand.

If you’re looking to reduce costs, boost output, and maintain top-tier quality in aerospace manufacturing, tungsten carbide tools from a trusted partner like Retop are your best option.