Les pompes de dessalement et d’eau saumâtre fonctionnent dans des conditions difficiles : salinité élevée, particules abrasives et pression constante.

Une étanchéité fiable est essentielle pour éviter les fuites, maintenir l’efficacité et réduire les temps d’arrêt.

Bagues d'étanchéité en carbure de tungstène sont largement utilisés dans ces systèmes en raison de leur durabilité, résistance à la corrosion, et une longue durée de vie.

Cet article explique leurs avantages, leurs applications et leurs meilleures pratiques pour les décideurs.

Pourquoi les pompes de dessalement et d'eau saumâtre ont besoin de joints solides

Prévenir les fuites → Protège les équipements coûteux et prévient la contamination.

Maintenir l'efficacité de la pompe → Des joints fiables réduisent les frottements et le gaspillage d’énergie.

Gérer une salinité élevée → L’eau salée est corrosive pour les matériaux plus fragiles.

Réduire les temps d'arrêt → Évitez les entretiens imprévus et les réparations coûteuses.

Protéger l'environnement → Empêche les fuites salines qui pourraient nuire aux écosystèmes.

Propriétés des bagues d'étanchéité en carbure de tungstène

Le carbure de tungstène est un composite de tungstène et de carbone, lié au cobalt ou au nickel. Ses propriétés comprennent :

Extrême dureté → Résiste à l’usure causée par les particules abrasives présentes dans l’eau de mer.

Haute résistance à la compression → Gère les hautes pressions dans les systèmes de dessalement.

Résistance à la corrosion → Protège contre la corrosion due à l’eau salée et à l’eau saumâtre.

Stabilité thermique → Fonctionne bien en cas de fluctuations de température.

Longue durée de vie → Réduit les coûts d’entretien et de remplacement.

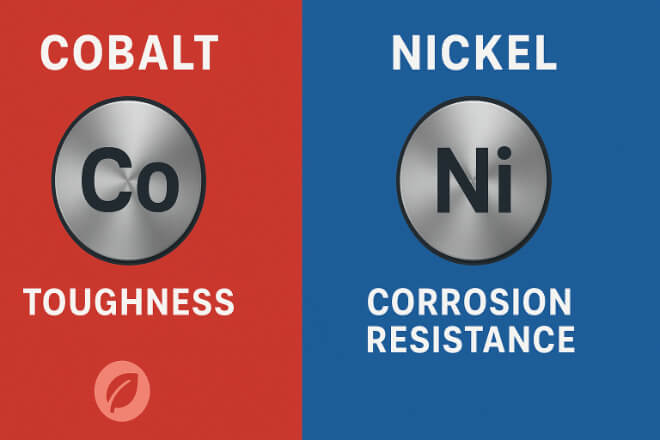

Carbure de tungstène lié au cobalt ou au nickel

1). Carbure de tungstène lié au cobalt

Offres plus élevées dureté pour pompes exposées aux vibrations.

Utilisé dans les systèmes où les chocs mécaniques sont une préoccupation.

2). Carbure de tungstène lié au nickel

Supérieur résistance à la corrosion pour les environnements à forte salinité.

Idéal pour les usines de dessalement côtières et les systèmes d’eau saumâtre.

Avantages par rapport aux autres matériaux d'étanchéité

| Fonctionnalité | Carbure de tungstène | Céramique | Acier |

|---|---|---|---|

| Résistance à l'usure | Excellent pour les abrasifs | Modéré | Pauvre |

| Résistance à la corrosion | Haute (teneurs en nickel) | Très bien | Faible |

| Dureté | Haut, résiste aux chocs | Faible, cassant | Modéré |

| Performance thermique | Excellent à haute température | Bien | Modéré |

| Durée de vie | Longue durée | Modéré | Court |

Applications dans les pompes de dessalement et d'eau saumâtre

Bagues d'étanchéité en carbure de tungstène sont utilisés dans :

Pompes à osmose inverse → Assure une étanchéité fiable sous haute pression.

Pompes d'admission et de surpression → Manipuler l’eau de mer avec des particules abrasives.

Systèmes de transfert d'eau saumâtre → Prévenir les défaillances liées à la corrosion.

Dispositifs de récupération d'énergie → Améliorer l’efficacité des usines de dessalement.

Unités de dessalement marines → Fonctionnez de manière fiable dans des conditions offshore.

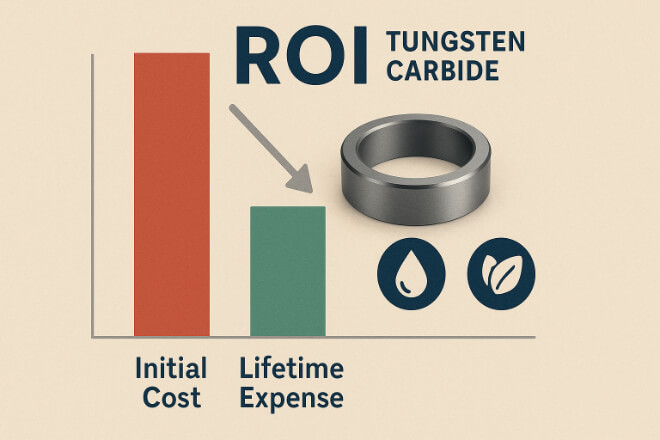

Coût vs valeur à long terme

Bien que les bagues d'étanchéité en carbure de tungstène puissent coûter plus cher au départ :

Réduire la maintenance → Une durée de vie plus longue signifie moins de remplacements.

Améliorer le retour sur investissement → Des temps d’arrêt réduits augmentent l’efficacité de la production.

Protéger l'équipement → Empêche les dommages coûteux aux pompes et aux canalisations.

Soutenir la durabilité → Moins de remplacements réduisent les déchets et la consommation d’énergie.

Avantages environnementaux et de sécurité

Prévention des fuites → Arrête les rejets salins nocifs dans l’environnement.

Matériau recyclable → Les bagues usagées peuvent être récupérées et retraitées.

Économies d'énergie → Des joints efficaces réduisent la consommation d’énergie.

Meilleures pratiques d'utilisation des bagues d'étanchéité en carbure de tungstène

Choisissez le bon classeur → Nickel lié pour une salinité élevée, cobalt lié pour les vibrations.

Inspectez régulièrement les joints → Détectez l’usure avant que les fuites ne se produisent.

Assurer une installation correcte → Évitez les désalignements et les rayures.

Travailler avec des fournisseurs expérimentés → Garantir la qualité des matériaux et des spécifications précises.

Planifier les calendriers de maintenance → Réduisez les temps d’arrêt imprévus.

Points clés à retenir pour les décideurs

Les bagues d'étanchéité en carbure de tungstène sont idéales pour les pompes de dessalement et d'eau saumâtre.

Leur durabilité, résistance à la corrosion, et l'efficacité surpasse celle de la céramique ou de l'acier.

Le coût initial plus élevé est compensé par une maintenance et des temps d’arrêt moindres.

L’utilisation du carbure de tungstène soutient les objectifs environnementaux et opérationnels.

Conclusion

Les systèmes de dessalement et d’eau saumâtre nécessitent des joints capables de supporter le sel, la pression et l’abrasion.

Les bagues d'étanchéité en carbure de tungstène offrent des performances supérieures, réduisent les fuites et améliorent la durée de vie de la pompe.

Pour les décideurs, investir dans le carbure de tungstène garantit un approvisionnement en eau fiable, des économies de coûts et une protection de l’environnement.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.