Power generation and marine equipment face some of the toughest working conditions in industry.

High pressure, heat, water, and corrosive environments place extreme demands on sealing components. If seals fail, the result is downtime, costly repairs, and even safety risks.

For this reason, many companies rely on bagues d'étanchéité en carbure de tungstène. These rings combine strength, résistance à l'usure, and durability to provide reliable sealing in harsh operating conditions.

This article explores how tungsten carbide seal rings are used in power generation and marine equipment, what makes them strong, and why they are the right choice for companies looking to reduce risks and improve efficiency.

Que sont les bagues d’étanchéité en carbure de tungstène ?

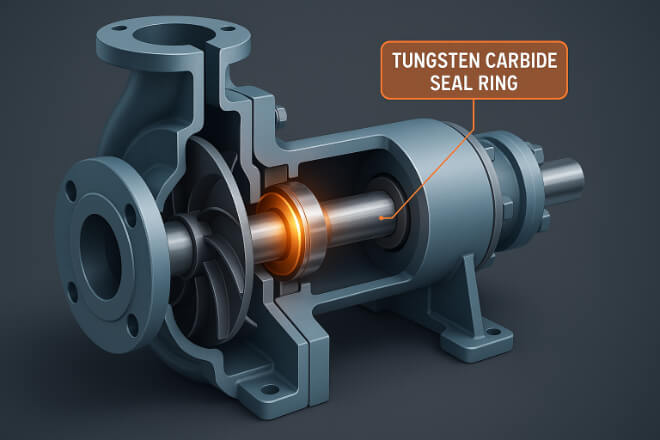

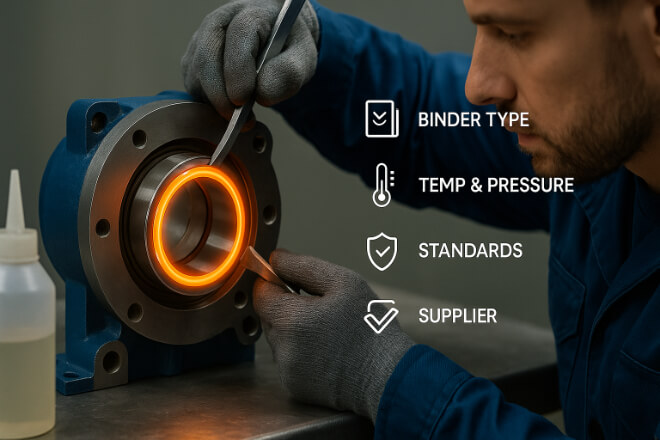

Tungsten carbide seal rings are circular components made from tungsten carbide, a material created by combining tungsten and carbon. To improve dureté, binders such as cobalt or nickel are added.

The result is a material that is nearly as hard as diamond, while still strong enough to resist cracking under pressure.

Seal rings are placed inside pumps, compressors, and vannes. Their role is simple but vital: to prevent leakage while allowing equipment to operate under high pressure and high temperature conditions.

Key Properties for Demanding Applications

The strength of tungsten carbide seal rings comes from their material structure. Important properties include:

Extrême Dureté – Protects against wear caused by friction and particles.

Compressive Strength – Allows rings to handle very high pressure without breaking.

Thermal Resistance – Ensures stability even at high temperatures found in power plants.

Résistance à la corrosion – Protects against seawater and chemicals in marine use.

Long Service Life – Reduces downtime and replacement costs.

These properties make tungsten carbide seal rings ideal for both power generation turbines and marine propulsion systems.

Seal Rings in Power Generation

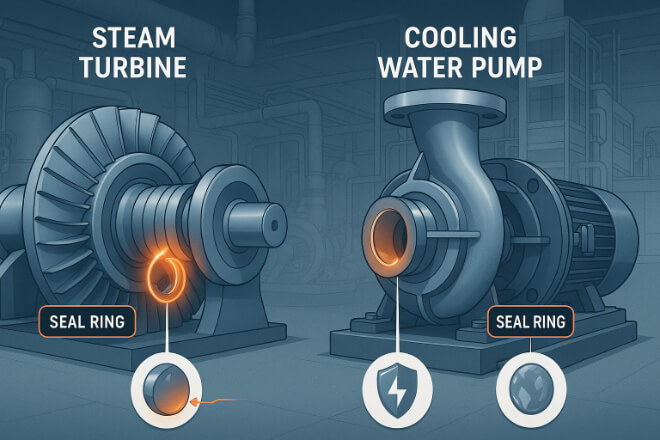

Power plants operate under continuous, high-demand conditions.

Pumps, turbines, and compressors must run reliably, often for long cycles without interruption. Failures can lead to large financial losses.

In this environment, tungsten carbide seal rings are used in:

Steam turbines to handle heat and pressure.

Cooling water pumps to resist erosion from water and particles.

Gas compressors to maintain performance under high load.

By reducing leakage and withstanding heat and pressure, these rings improve both safety and efficiency in power plants.

Seal Rings in Marine Equipment

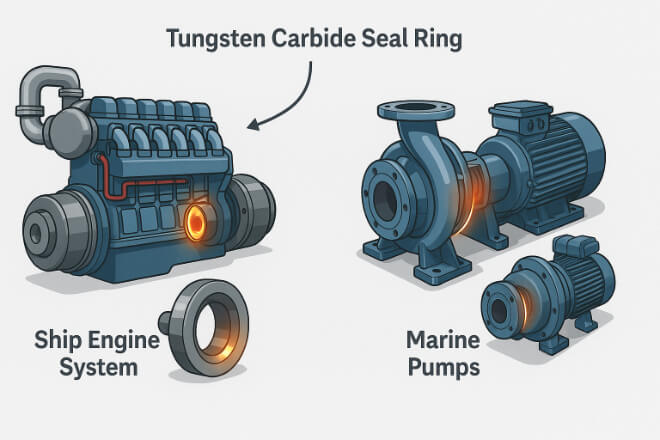

Marine environments are highly corrosive due to constant contact with seawater.

Ship engines, pumps, and offshore equipment require seals that can handle both mechanical stress and saltwater corrosion.

Les bagues d'étanchéité en carbure de tungstène sont largement utilisées dans :

Marine pumps – For ballast, cooling, and circulation systems.

Propulsion systems – To ensure efficient and safe operation.

Offshore drilling equipment – Where pressure and seawater corrosion are combined.

By providing long-lasting sealing solutions, these rings help reduce maintenance costs and ensure reliable operation at sea.

Comparaison avec d'autres matériaux d'étanchéité

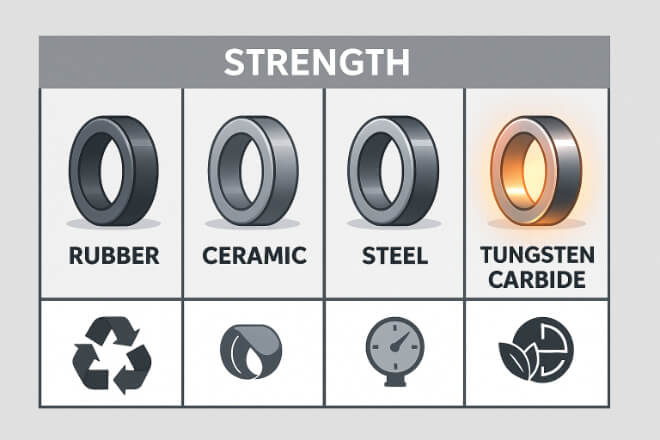

While rubber, ceramic, and steel seals are common, they do not perform as well in high-stress or corrosive conditions:

Rubber seals fail quickly under heat and pressure.

Ceramic seals are hard but brittle, breaking under impact.

Steel seals corrode in seawater and wear down faster.

Tungsten carbide seal rings provide the right balance of dureté, la force et résistance à la corrosion, making them superior in both power and marine industries.

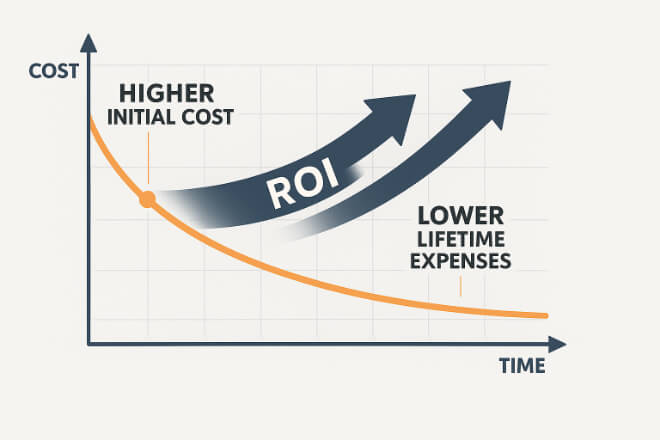

Coût vs valeur à long terme

Although tungsten carbide seal rings are more expensive at purchase, their long service life offers better long-term value.

Less downtime – Equipment stays in operation longer.

Lower replacement needs – Rings last much longer than alternatives.

Higher ROI – Reduced failure costs and improved reliability.

For decision-makers, this means lower total cost of ownership, even if the initial investment is higher.

Best Practices for Maintenance

To maximize performance, companies should:

Install correctly to avoid misalignment and damage.

Inspect regularly for wear or cracks.

Use proper lubrication to minimize friction.

Select the right grade (nickel- or cobalt-bonded) depending on the environment.

Good practices extend the already long life of tungsten carbide seal rings, ensuring maximum efficiency.

Durabilité et recyclage

Another advantage is that tungsten carbide seal rings are recyclable. Many suppliers collect used rings and recycle them into new components.

This reduces waste, supports environmental goals, and makes the material more sustainable.

Conclusion

In both power generation and marine industries, reliable sealing is essential for safety, performance, and cost control.

Tungsten carbide seal rings stand out because they resist wear, pressure, heat, and corrosion better than other materials.

For decision-makers, choosing tungsten carbide seal rings is not only a technical choice but also a strategic investment in long-term efficiency and reliability.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.