Renewable energy systems—such as wind turbines, hydroelectric plants, solar farms with pumps, and geothermal systems—operate under tough environmental conditions.

Their components must run for years with minimal maintenance to keep energy production efficient and cost-effective.

One critical component is the seal ring. In pumps, turbines, and compressors, seals prevent fluid leaks, protect bearings, and ensure energy efficiency.

Among available materials, tungsten carbide seal rings offer superior performance for renewable energy equipment.

Why Seal Rings Matter in Renewable Energy Systems

Seal failures can:

Cause fluid leaks in hydraulic or coolant systems.

Increase downtime, reducing energy output.

Lead to extra maintenance costs and safety risks.

Lower equipment efficiency, wasting renewable energy.

Reliable seals ensure continuous operation and better return on investment for wind, hydro, solar, and geothermal projects.

Principales propriétés des bagues d'étanchéité en carbure de tungstène

Tungsten carbide is a composite of tungsten and carbon, bonded with cobalt or nickel. Its key properties include:

Extrême dureté → Resists wear from abrasive particles.

Haute résistance à la compression → Handles high loads and pressures.

Résistance à la corrosion → Protects against water, chemicals, or steam.

Stabilité thermique → Maintains performance in hot geothermal or turbine systems.

Longue durée de vie → Reduces waste and maintenance.

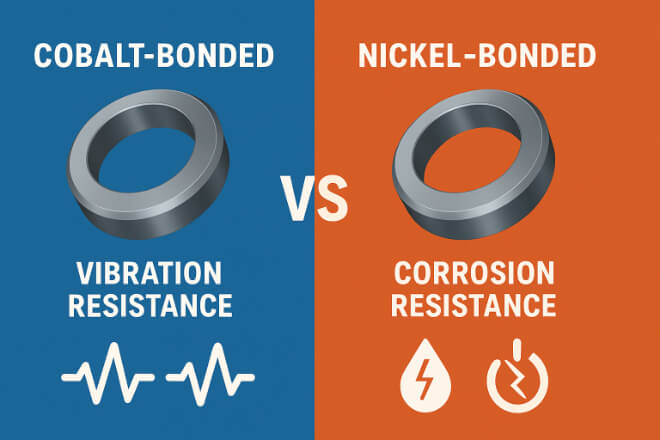

Carbure de tungstène lié au cobalt ou au nickel

1). Carbure de tungstène lié au cobalt

More dureté et résistance aux chocs.

Best for wind turbines or hydro systems with vibration.

2). Carbure de tungstène lié au nickel

Supérieur corrosion resistance.

Ideal for geothermal and marine renewable equipment where water and chemicals are present.

Avantages par rapport aux autres matériaux d'étanchéité

| Fonctionnalité | Carbure de tungstène | Céramique | Acier |

|---|---|---|---|

| Résistance à l'usure | Excellent | Modéré | Pauvre |

| Résistance à la corrosion | Haute (teneurs en nickel) | Très bien | Faible |

| Dureté | Haut, résiste aux chocs | Faible, cassant | Modéré |

| Performance thermique | Excellent à haute température | Bien | Modéré |

| Durée de vie | Longue durée | Modéré | Court |

Applications in Renewable Energy Equipment

Les bagues d'étanchéité en carbure de tungstène sont utilisées dans :

Wind turbines → Gearboxes and hydraulic systems.

Hydroelectric plants → Pumps and turbines handling water with debris.

Solar farms → Cooling and circulation pumps.

Geothermal plants → High-temperature pumps and compressors.

Marine energy systems → Tidal and wave energy converters exposed to seawater.

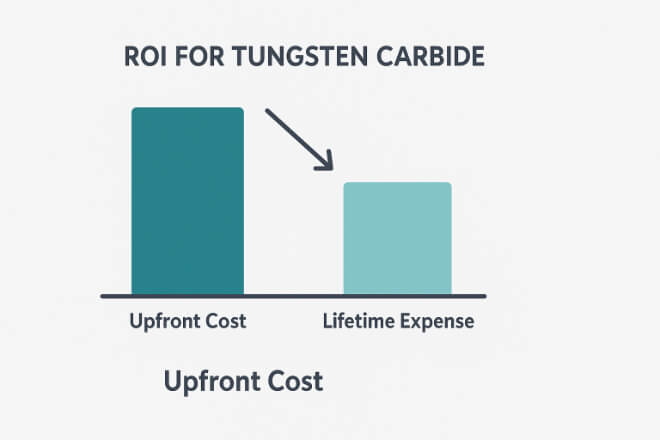

Coût vs valeur à long terme

While tungsten carbide seal rings cost more upfront:

They last longer, reducing downtime and maintenance.

They prevent leaks that can damage expensive renewable equipment.

Their durability leads to better ROI over the project’s lifetime.

Avantages environnementaux

Matériau recyclable → Worn rings can be recovered and reused.

Less waste → Fewer replacements mean reduced landfill disposal.

Higher efficiency → Preventing leaks saves energy and reduces emissions.

For renewable energy companies committed to sustainability, tungsten carbide aligns with green operational goals.

Best Practices for Choosing and Using Tungsten Carbide Seal Rings

Evaluate the operating environment → Corrosive water? High vibration? Choose the right binder.

Travailler avec des fournisseurs expérimentés → Ensure correct specifications for renewable systems.

Install correctly → Avoid scratches or misalignment that cause leaks.

Inspecter régulièrement → Prevent failures before they cause costly downtime.

Recycle worn rings → Support circular manufacturing and sustainability.

Points clés à retenir pour les décideurs

Tungsten carbide seal rings ensure durability, efficiency, and sustainability in renewable energy equipment.

Choose nickel-bonded for corrosion-heavy environments and cobalt-bonded for vibration-heavy systems.

The higher upfront cost is justified by long-term savings and environmental benefits.

Reliable seals improve energy production and equipment protection across wind, hydro, solar, geothermal, and marine systems.

Conclusion

Renewable energy equipment must operate reliably for decades under demanding conditions. Tungsten carbide seal rings provide the hardness, strength, and corrosion resistance needed for these critical systems.

For decision-makers, investing in tungsten carbide seal rings supports efficiency, cost savings, and environmental responsibility, making them the smart choice for renewable energy operations.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.