Exploitation minière is one of the toughest industries in the world. Equipment is pushed to its limits every day, working under high pressure, high heat, and in abrasive conditions.

In such environments, tool failure can lead to costly downtime and reduced productivity. This is where pièces d'usure en carbure de tungstène become essential.

Tungsten carbide is a material known for its extreme dureté, résistance à l'usure, et dureté. When used in mining, it helps machines last longer, work faster, and reduce overall maintenance costs.

This article explains the role of tungsten carbide wear parts in mining, their benefits, applications, and factors to consider when choosing them.

Que sont les pièces d’usure en carbure de tungstène ?

Tungsten carbide wear parts are components made from a composite of tungsten and carbon atoms, bonded with cobalt or nickel as a binder.

These parts are engineered to resist wear, abrasion, and impact, even under the harshest mining conditions.

Common tungsten carbide wear parts in mining include:

Cutting tools for drilling and excavation

Plaques d'usure and liners for crushers

Buttons and inserts for drill bits

Nozzles for slurry handling

Scraper blades and bucket teeth

Their main function is to extend equipment life and keep production running efficiently.

Why Mining Requires High-Performance Wear Parts

The mining industry involves:

Continuous contact with abrasive materials such as rock, ore, and minerals

High mechanical loads that can cause tool deformation or breakage

Harsh environmental factors like dust, water, and extreme temperatures

Standard steel parts often wear out too quickly in such conditions.

Tungsten carbide parts can last several times longer, which means fewer replacements, lower maintenance costs, and more uptime.

Benefits of Tungsten Carbide Wear Parts in Mining

1). Exceptional Résistance à l'usure

Tungsten carbide ranks close to diamond on the Mohs hardness scale, making it extremely resistant to scratching and abrasive wear.

2). High Impact Strength

Modern carbide formulations are designed to absorb impact without breaking, essential for crushing and drilling applications.

3). Heat Resistance

Carbide wear parts can maintain their dureté even at high temperatures, ideal for deep drilling or high-speed cutting.

4). Corrosion Resistance

Carbide resists rust and chemical attack, extending life in wet mining environments.

5). Cost Savings

Although carbide parts have a higher upfront cost, they reduce downtime and replacement frequency, lowering total operating costs.

Key Applications in Mining

Here are some common uses of tungsten carbide wear parts in the mining industry:

| Mining Application | Tungsten Carbide Part Example | Fonction |

|---|---|---|

| Forage | Drill bit buttons and inserts | Cut and break rock efficiently |

| Crushing | Crusher wear plates, liners | Protect crusher surfaces from abrasion |

| Material Handling | Slurry pump nozzles, impellers | Resist erosion from high-speed slurry |

| Excavation | Bucket teeth, cutting edges | Maintain sharp cutting surfaces longer |

| Screening & Sorting | Screen panels, wear bars | Prolong life of material sorting equipment |

Choosing the Right Tungsten Carbide Wear Parts for Mining

When selecting carbide wear parts for mining operations, decision-makers should consider:

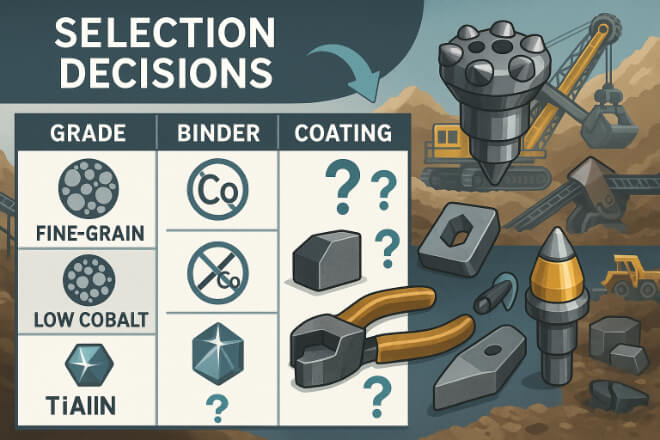

1). Grade Selection

Tungsten carbide comes in different grades, each optimized for hardness, toughness, or corrosion resistance. For example:

Coarse grain carbide for high-impact tools

Fine grain carbide for precision cutting and abrasion resistance

2). Binder Content

Cobalt or nickel binders affect toughness and corrosion resistance. Higher binder content improves toughness but may reduce hardness.

3). Coating Options

Some carbide parts are coated with TiN, TiAlN, or diamond-like coatings to further improve wear and corrosion resistance.

4). Operating Conditions

Parts should be matched to the specific rock type, temperature range, and moisture level in the mining environment.

Maintenance Tips for Longer Service Life

To get the most from tungsten carbide wear parts:

Regularly inspect for signs of chipping or excessive wear

Use correct installation methods to avoid stress fractures

Match parts to application — don’t use drilling-grade carbide for crushing applications

Follow lubrication guidelines to prevent overheating

Store properly to avoid corrosion before use

Cost vs. Value Consideration

It is important to understand that lowest price is not always the best choice in mining.

While steel parts may be cheaper initially, they often require more frequent replacement, leading to higher downtime costs.

Tungsten carbide wear parts, despite their higher initial investment, deliver better cost efficiency over time due to reduced replacements and higher productivity.

The Future of Tungsten Carbide in Mining

With advancements in nanostructured carbides, improved binder formulas, and additive manufacturing, the future of tungsten carbide wear parts looks even more promising.

These innovations are expected to deliver even higher durability, lighter weight, and better customization for different mining conditions.

Conclusion

Tungsten carbide wear parts are essential for modern mining operations that demand reliability, efficiency, and cost control.

They provide unmatched wear resistance, toughness, and heat tolerance, making them the top choice for drilling, crushing, and material handling.

For decision-makers, investing in the right tungsten carbide wear parts means less downtime, lower maintenance costs, and higher productivity — all critical factors in staying competitive in the mining industry.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.