Dans le monde des matériaux et de l'outillage de pointe, la granulométrie est un terme fréquemment utilisé. Bien que cela puisse sembler être un détail réservé aux métallurgistes, la granulométrie joue un rôle essentiel dans la performance, la résistance et la durabilité des outils en carbure de tungstène utilisés dans les secteurs de l'exploitation minière, de l'usinage, du pétrole et du gaz, et de la fabrication de précision.

Alors, qu’est-ce que la granulométrie et pourquoi devriez-vous vous en soucier ?

Qu'est-ce que la granulométrie ?

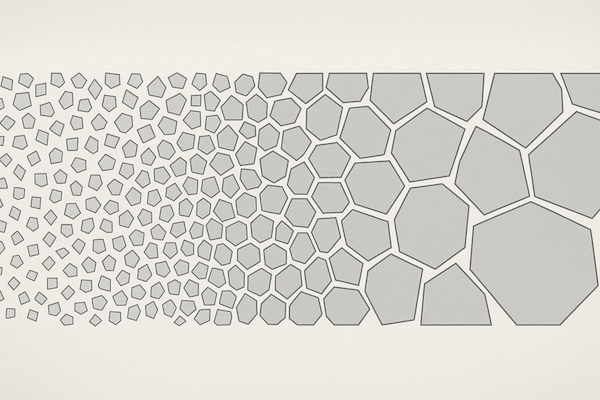

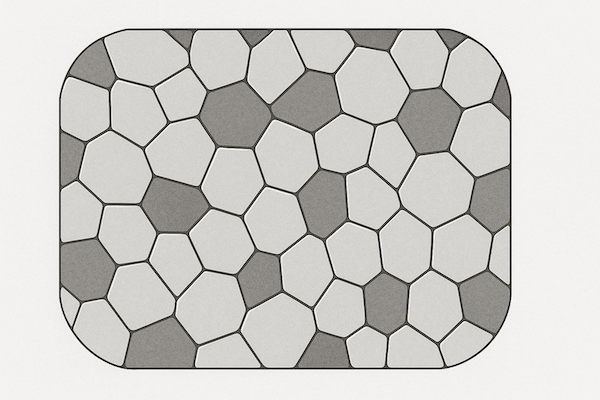

La granulométrie désigne la taille moyenne des particules individuelles de carbure de tungstène (WC) dans un matériau en carbure cémenté. Ces particules sont étroitement liées entre elles par un liant métallique (généralement du cobalt ou du nickel), formant un matériau composite aux propriétés exceptionnelles. dureté et force.

Les tailles de grains sont généralement mesurées en microns (μm) et sont généralement classées en :

Ultrafin (< 0,5 μm)

Submicronique (0,5 – 1,0 μm)

Fin (1 – 2 μm)

Moyen (2 – 6 μm)

Grossier (> 6 μm)

Comment la taille des grains affecte les performances des outils en carbure de tungstène

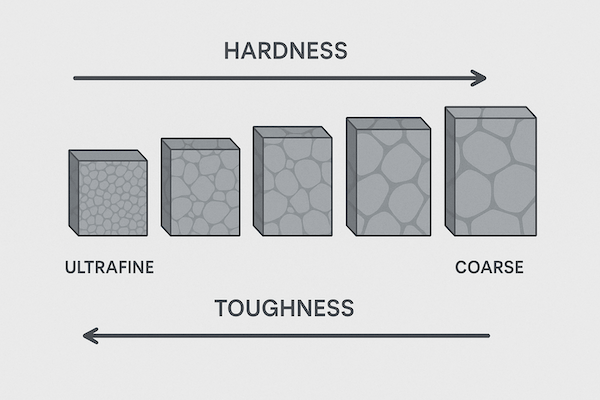

La taille des grains influence directement les propriétés mécaniques du matériau, notamment la dureté, résistance à l'usure, duretéet comportement thermique. Voici comment :

| Taille des grains | Dureté | Dureté | Résistance à l'usure | Application typique |

|---|---|---|---|---|

| Ultrafin | Très élevé | Faible | Excellent (pour la précision) | Forets pour circuits imprimés, micro-fraises |

| Submicronique | Haut | Modéré | Excellent | Plaquettes de coupe en métal |

| Bien | Modéré | Bien | Bien | Usinage à usage général |

| Moyen | Équilibré | Mieux | Modéré | Pioches minières, pièces d'usure |

| Grossier | Inférieur | Excellent | Inférieur | Outils à percussion, perçage intensif |

Grains plus petits = dureté plus élevée mais plus cassant.

Grains plus gros = meilleure ténacité mais dureté plus faible.

Pourquoi contrôler la taille des grains dans la fabrication du carbure ?

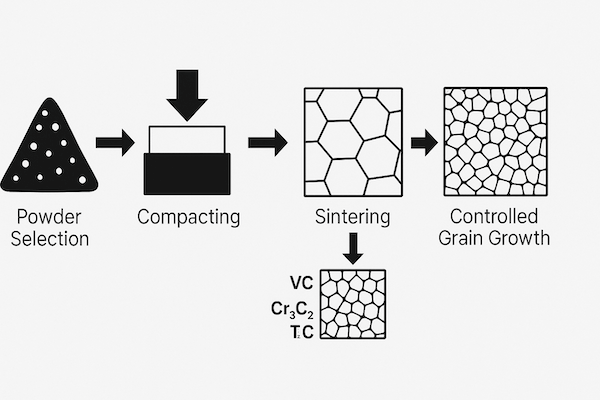

Les fabricants contrôlent soigneusement la taille des grains à l'aide de techniques de préparation de poudre et de frittage car :

Le raffinement du grain améliore la résistance à l'usure et la rétention des bords

Les grains plus grossiers offrent une meilleure résistance aux chocs dans des conditions de charge de choc

La granulométrie uniforme garantit des performances uniformes de l'outil

La taille des grains affecte également le retrait de frittage et les tolérances finales

L'équilibrage de la taille des grains est essentiel pour adapter les outils à des applications spécifiques : trop fin et l'outil peut s'écailler ; trop grossier et il peut s'user trop rapidement.

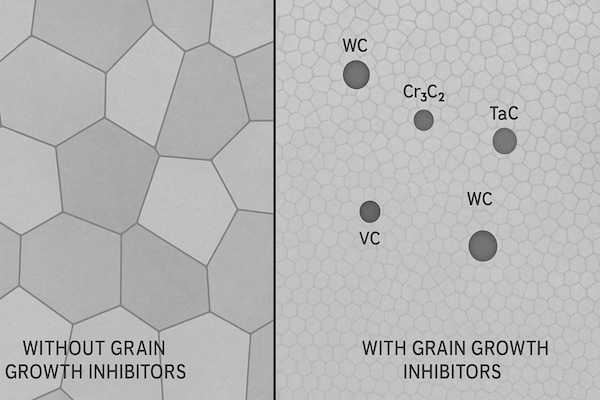

Croissance des grains et additifs

Lors du frittage, les grains de WC ont naturellement tendance à grossir. Pour éviter une croissance excessive et préserver les propriétés souhaitées, les fabricants ajoutent souvent des inhibiteurs de croissance des grains, tels que :

Carbure de vanadium (VC)

Carbure de chrome (Cr₃C₂)

Carbure de tantale (TaC)

Ces additifs stabilisent la microstructure et aident à maintenir la cohérence des performances dans des conditions d'usinage ou de coupe extrêmes.

Conclusion

La taille des grains peut être invisible à l’œil nu, mais son impact sur outils en carbure de tungstène est profond. Des micro-forets ultra-précis aux pics miniers robustes, le choix de la granulométrie adéquate est essentiel pour obtenir l'équilibre parfait entre dureté, robustesse et résistance à l'usure.

La compréhension de la granulométrie n'est pas réservée uniquement aux scientifiques : elle est essentielle pour optimiser les performances des outils et garantir une durée de vie plus longue sur le terrain.