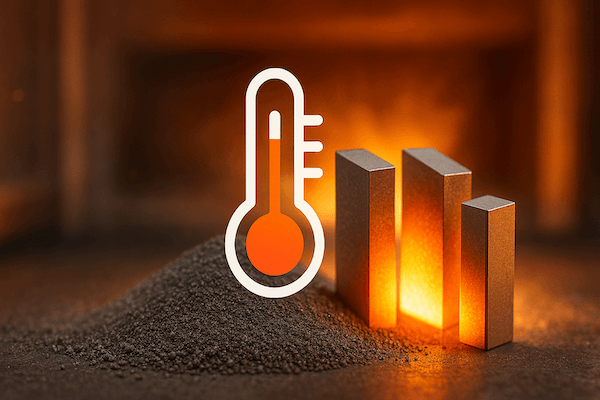

La température de frittage est un facteur critique dans la production d'outils en carbure de tungstène (WC), influençant directement leur dureté, force, microstructure, et les performances globales. Dans cet article, nous explorerons la signification de la température de frittage, son rôle dans la production d'alliages durs et pourquoi un contrôle précis est essentiel à la production. outils en carbure de haute qualité.

https://www.retopz.com/wp-content/uploads/2025/06/Understanding-Sintering-Temperature-in-Tungsten-Carbide-Tool-Manufacturing.png

Qu'est-ce que la température de frittage ?

La température de frittage désigne la température élevée à laquelle les matériaux en poudre sont compactés et fusionnés sans atteindre leur point de fusion. Dans le cas des outils en carbure de tungstène, le procédé implique généralement le chauffage d'un mélange de Poudre de WC et un liant métallique, généralement du cobalt (Co) ou du nickel (Ni), à une température comprise entre 1 350 °C et 1 500 °C dans une atmosphère contrôlée.

À cette température, le liant métallique fond et s'infiltre dans les particules de carbure de tungstène, favorisant la densification et la liaison des grains. Le résultat final est un matériau solide et hautement résistant. matériau composite.

Pourquoi la température de frittage est importante

1. Formation de microstructures

La température de frittage contrôle la croissance des particules de WC et la répartition de la phase liante. Une température optimale assure :

Uniforme granulométrie

Haut densité

Liaison métallurgique forte

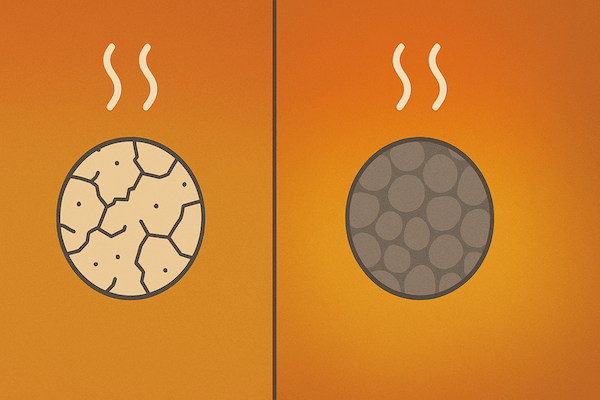

Un frittage incorrect (trop bas ou trop élevé) peut entraîner porosité, une liaison faible ou une croissance excessive des grains, qui réduisent tous la durée de vie et les performances de l'outil.

2. Propriétés mécaniques

Les propriétés mécaniques du carbure de tungstène, telles que dureté, dureté, et résistance à l'usure—sont étroitement liés à la température de frittage :

Des températures plus élevées peuvent améliorer la liaison des grains, mais peuvent réduire la ténacité en raison du grossissement des grains.

Température plus basses peut préserver les grains fins mais entraîner une densification incomplète et une fragilité.

L’équilibre entre ces facteurs est essentiel pour des applications allant des outils d’exploitation minière et de coupe aux pièces d’usure de précision.

3. Stabilité de phase

Aux températures de frittage, le système WC-Co peut former des phases indésirables, comme la phase êta (η) ou le graphite libre, s'il n'est pas soigneusement contrôlé. Une température de frittage précise contribue à :

Prévenir la formation de phases cassantes

Maintenir la microstructure souhaitée du WC biphasé et du liant

Frittage dans la production d'outils en carbure de tungstène

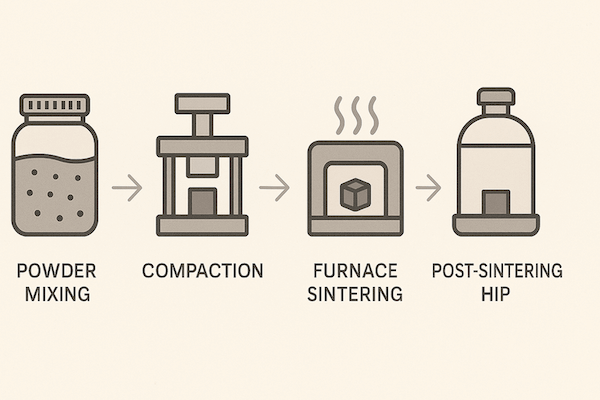

Dans le moderne fabrication d'outils en carbure de tungstèneLe frittage est l'étape finale, la plus énergivore. Les étapes clés sont les suivantes :

Mélange de poudre – La poudre WC est mélangée avec du cobalt ou d’autres liants, ainsi qu’avec des inhibiteurs de croissance des grains comme le VC ou le Cr₃C₂.

Compactage – Le mélange est pressé dans la forme souhaitée (par exemple, des flans, des inserts).

Frittage – Les compacts verts sont frittés sous vide ou sous atmosphère d’hydrogène à des températures contrôlées.

Traitements post-frittage – Des procédés secondaires tels que le HIP (Hot Isostatic Pressing) peuvent être appliqués pour éliminer la porosité interne.

La température de frittage doit être optimisée en fonction de la qualité du matériau, de la géométrie de l'outil et des exigences de performance.

Conclusion

La température de frittage joue un rôle fondamental dans la fabrication de pièces hautes performances. outils en carbure de tungstèneIl détermine les propriétés physiques, la longévité et la consistance du produit final. Les producteurs de carbure de pointe utilisent des systèmes de contrôle de température stricts, des fours sophistiqués et une surveillance en temps réel pour obtenir des résultats de frittage optimaux. La compréhension et la gestion de ce paramètre clé garantissent que les outils en carbure de tungstène répondent aux exigences rigoureuses de l'industrie moderne, du métallurgie. coupe et exploitation minière à électronique et aérospatial.