En matière d’usinage, le choix du bon outil de coupe peut faire une grande différence dans vos résultats, et au cœur de bon nombre de ces outils se trouve le carbure.

Mais tous les carbures ne se valent pas. Il existe différents types et nuances, chacun étant conçu pour des applications spécifiques.

Si vous êtes un décideur dans le secteur de l'usinage, comprendre les types de carbure dans les outils de coupe peut vous aider à prendre des décisions d'achat plus intelligentes, à réduire l'usure des outils et à améliorer la qualité des pièces.

Dans ce guide, nous allons décomposer les différents types de carbure utilisés dans les outils de coupe, expliquer ce qui les rend différents et vous proposer des conseils pour vous aider à choisir celui qui convient à votre travail.

Qu'est-ce que le carbure et pourquoi est-il utilisé dans les outils de coupe ?

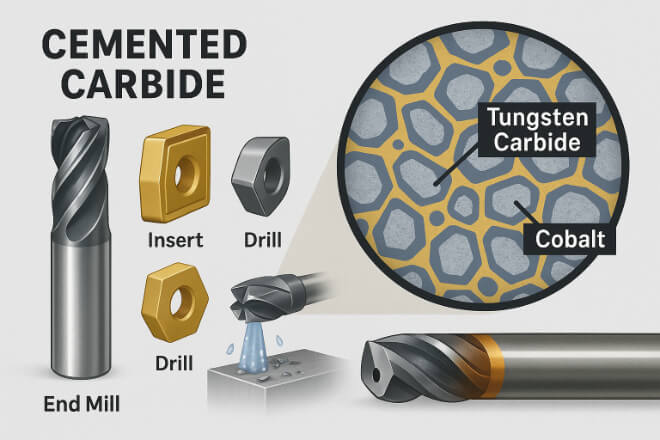

Le carbure est un matériau dur et dense fabriqué en combinant des atomes de tungstène et de carbone dans un composé appelé carbure de tungstène (WC).

Ce matériau est ensuite mélangé à un liant, généralement du cobalt, et pressé pour former un outil de coupe solide et très résistant.

Le carbure est largement utilisé dans les outils de coupe en raison de :

Dureté extrême : il reste tranchant plus longtemps.

Résistance à l'usure:Il peut couper même des métaux durs comme l'acier inoxydable et le titane.

Résistance à la chaleur : Il fonctionne bien à grande vitesse sans perdre son tranchant.

C'est pourquoi les outils en carbure sont souvent le premier choix dans des industries comme automobile, aérospatial, pétrole et gaz, fabrication de moules, et la fabrication générale.

Carbure cémenté : la norme de l'industrie

Le type de carbure le plus couramment utilisé dans les outils de coupe est le carbure cémenté, également connu sous le nom de métal dur.

Il est fabriqué en mélangeant des particules de carbure de tungstène avec un liant métallique, généralement du cobalt, et en les frittant à haute température.

Selon la manière dont il est fabriqué, le carbure cémenté peut être optimisé pour différentes applications :

Plus de cobalt = plus dureté (mais légèrement moins de résistance à l'usure)

Moins de cobalt = outil plus dur (mais peut s'écailler sous de lourdes charges)

Cet équilibre entre dureté et la robustesse est essentielle lors du choix d'une nuance.

Le carbure cémenté est utilisé dans :

Inserts

Exercices

Outils de tournage

Grades C et grades ISO : comprendre la classification

Les outils en carbure sont souvent étiquetés en utilisant soit Notes C (aux États-Unis) ou Grades ISO (à l'échelle internationale)Ces systèmes de classement aident les utilisateurs à faire correspondre un outil à la bonne application.

1). Notes C courantes aux États-Unis :

| Grade | Application |

|---|---|

| C1–C2 | Fonte, métaux non ferreux |

| C3–C4 | Usinage à usage général |

| C5–C6 | Découpe de l'acier |

| C7–C8 | Haute résistance à l'usure, applications difficiles |

2). Grades ISO courants :

| Qualité ISO | Application |

|---|---|

| P | Acier |

| K | Fonte |

| M | Acier inoxydable |

| N | Métaux non ferreux (aluminium, cuivre) |

| S | Alliages haute température (Inconel, etc.) |

| H | Aciers trempés |

Chaque nuance est conçue pour gérer une combinaison spécifique d’usure, de ténacité et de résistance à la température.

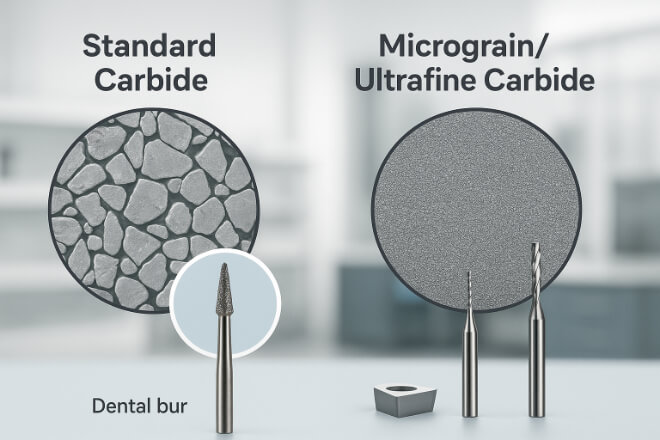

Micrograin et carbure ultrafin : haute précision, haute résistance

Toutes les particules de carbure n'ont pas la même taille. Certaines sont extrêmement fines : on les appelle micrograins ou carbure ultrafin. Ces petits grains produisent un matériau plus lisse et plus résistant.

1). Avantages du carbure micrograin :

Excellente netteté des bords

Ténacité supérieure par rapport au carbure à grains fins ordinaire

Idéal pour les petits outils comme les micro-fraises, les fraises dentaires ou les forets de précision

2). Utilisations typiques :

Usinage électronique

Fabrication d'outils médicaux

Fabrication de moules de haute précision

Si votre travail implique des tolérances serrées ou des caractéristiques minuscules, les outils en carbure micrograin peuvent être votre meilleur choix.

Outils en carbure revêtus ou non revêtus

Bien que le matériau de base d’un outil soit important, les revêtements jouent également un rôle important dans les performances de l’outil.

Les outils en carbure peuvent être non revêtus ou revêtus de matériaux tels que TiAlN, TiCN ou carbone de type diamant (DLC).

| Fonctionnalité | Carbure revêtu | Carbure non revêtu |

|---|---|---|

| Résistance à l'usure | Haut | Modéré |

| Résistance à la chaleur | Excellent | Modéré |

| Finition de surface | Amélioré | Cela dépend de l'application |

| Coût | Plus élevé à l'avance | Inférieur |

Utilisez du carbure revêtu pour l'usinage de matériaux durs ou abrasifs. Privilégiez les outils non revêtus pour les métaux plus tendres, les plastiques ou les opérations à basse vitesse.

Carbure recyclé : bon pour la planète et votre budget

Un autre type de carbure qui suscite un intérêt croissant est le carbure recyclé. Les outils en carbure usagés peuvent être récupérés, rectifiés et réutilisés pour fabriquer de nouveaux outils.

Certains fournisseurs proposent du carbure recyclé de haute qualité qui fonctionne presque aussi bien que le matériau vierge.

Avantages du carbure recyclé :

Coût inférieur

Réduit l'impact environnemental

Aide les entreprises à atteindre leurs objectifs de développement durable

Assurez-vous de vérifier la qualité et l'origine des outils recyclés. Un fournisseur réputé les étiquettera et les testera clairement.

Sélection du carbure adapté à votre application

Voici un guide rapide pour vous aider à faire correspondre les types de carbure à votre application :

| Matériau coupé | Type de carbure recommandé | Revêtement préféré |

|---|---|---|

| Acier | C5 / ISO P | TiAlN |

| Acier inoxydable | C6 / ISO M | TiCN |

| Aluminium | C2 / ISO N | DLC ou non enrobé |

| Fonte | C1–C2 / ISO K | Étain |

| Inconel ou alliages de titane | ISO S | TiAlN ou AlTiN |

| Acier trempé | ISO H | Revêtements CVD diamant ou spéciaux |

Points clés à retenir pour les décideurs

Si vous êtes responsable de la sélection ou de l'approbation des outils de coupe dans votre atelier ou votre entreprise, voici ce qu'il faut retenir :

Tous les carbures ne sont pas identiques : différentes nuances et tailles de grains conviennent à différents travaux.

Les revêtements améliorent les performances, en particulier dans les matériaux à grande vitesse ou difficiles.

Les outils en carbure micrograin offrent une précision et une résistance supérieures pour les petites pièces.

Le carbure recyclé est écologique et rentable, s’il est correctement approvisionné.

Tenez toujours compte à la fois du matériau de l’outil et des revêtements lors du choix d’applications spécifiques.

Réflexions finales

Comprendre les types de carbure utilisés dans les outils de coupe n’est pas seulement technique : c’est une décision commerciale intelligente.

Avec les bonnes connaissances, vous pouvez prendre de meilleures décisions qui affectent vos résultats, la durée de vie de vos outils et la qualité de votre usinage.

Que vous usiniez des alliages aérospatiaux, des pièces automobiles ou des composants médicaux, il existe une nuance de carbure conçue pour ce travail.

Prenez le temps d’apprendre les options, travaillez avec des fournisseurs de confiance et gardez toujours votre application à l’esprit.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.