Tungsten carbide tips are essential in many industrial applications, from drilling and cutting to mining and construction.

What makes these tips so effective is their microstructure—the arrangement of particles and phases that give the material its unique properties.

Understanding the microstructure of tungsten carbide is crucial for optimizing its performance in tough environments.

This blog will explore the different components of tungsten carbide’s microstructure and how they influence its properties, particularly its dureté, résistance à l'usure, and overall durability.

Qu'est-ce que le carbure de tungstène ?

Tungsten carbide is a compound made from tungsten and carbon.

It is known for its exceptional dureté and ability to withstand wear and high temperatures. Tungsten carbide is commonly used in tools such as cutting inserts, drill bits, and saw blades.

The performance of these tools depends heavily on the microstructure of the tungsten carbide used to manufacture them.

Key Components of Tungsten Carbide:

Tungsten: The metal provides hardness and strength.

Carbon: Carbon atoms combine with tungsten to form the carbide, enhancing hardness and wear resistance.

Matériau de liaison: Tungsten carbide is often combined with a binder material, like cobalt or nickel, to provide toughness and flexibility.

The Role of Grain Size in Tungsten Carbide

One of the most important factors in determining the performance of tungsten carbide tips is the size of the grains in its microstructure.

Taille des grains influences the hardness, toughness, and wear resistance of the material. Smaller grains tend to improve hardness and wear resistance, while larger grains increase toughness and impact resistance.

Fine vs. Coarse Grains:

Fine Grains: These grains provide better résistance à l'usure et dureté, making the material ideal for cutting and machining applications.

Coarse Grains: These grains offer improved dureté, making the material better suited for high-impact applications such as mining tools.

Table: Fine vs. Coarse Grains in Tungsten Carbide

| Taille des grains | Avantages | Applications idéales |

|---|---|---|

| Fine Grains | Higher hardness, better wear resistance | Cutting, machining, precision tools |

| Coarse Grains | Increased toughness, improved impact resistance | Mining, drilling, heavy machinery |

The Influence of Binder Materials on Microstructure

Binder materials like cobalt and nickel play a crucial role in the microstructure of tungsten carbide.

These materials help to hold the tungsten carbide particles together and provide toughness to the otherwise brittle carbide.

The choice of binder material affects the overall mechanical properties of the tungsten carbide tips.

Cobalt vs. Nickel Binders:

Cobalt: Cobalt is the most common binder used in tungsten carbide. It provides excellent wear resistance and enhances the material’s ability to withstand heat and pressure.

Nickel: Nickel-based binders are often used when improved résistance à la corrosion is required, especially in industries like oil and gas.

The Phases of Tungsten Carbide

Tungsten carbide exists in two primary phases: alpha phase and beta phase. The distribution and amount of each phase in the microstructure play a significant role in determining the material’s overall properties.

Alpha Phase: The alpha phase is stable at lower temperatures and contributes to the hardness of the material.

Beta Phase: The beta phase is more ductile and helps improve toughness and impact resistance.

The balance between these phases is carefully controlled during the manufacturing process to achieve the desired properties in tungsten carbide tools.

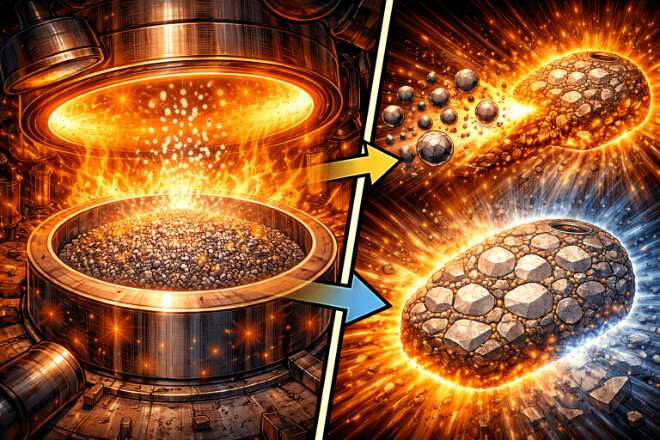

The Sintering Process and Its Impact on Microstructure

The sintering process is critical in determining the final microstructure of tungsten carbide.

During sintering, the poudre de carbure de tungstène is heated to high temperatures, causing the particles to fuse together.

The temperature and time during sintering influence the grain size and phase distribution, which directly affects the material’s properties.

Key Factors in Sintering:

Température: Higher sintering temperatures result in larger grains, while lower temperatures produce finer grains.

Temps: Longer sintering times allow for better grain growth and phase transformation.

Pression: The application of pressure during sintering can help achieve more uniform grain distribution.

Tungsten Carbide Tips in Industrial Applications

Understanding the microstructure of tungsten carbide is essential for choosing the right material for various industrial applications.

The microstructure influences wear resistance, hardness, toughness, and overall tool life, making it a critical factor in industries such as mining, construction, and machining.

Table: Industrial Applications of Tungsten Carbide Tips

| Industrie | Applications |

|---|---|

| Exploitation minière | Drill bits, rock tools |

| Machining | Cutting tools, inserts |

| Construction | Concrete cutters, road planers |

Conclusion

The microstructure of tungsten carbide tips is a key factor in their superior hardness, wear resistance, and overall performance.

By understanding the roles of grain size, binder materials, phases, and the sintering process, industries can optimize the use of tungsten carbide tips in various demanding applications.

The careful control of these factors ensures that tungsten carbide tips provide maximum durability and performance, making them a valuable asset in industries that require reliable cutting, drilling, and mining tools.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.