Les billes en carbure de tungstène sont de petites pièces sphériques fabriquées à partir d'un matériau extrêmement dur appelé carbure de tungstène. Ces billes sont utilisées dans de nombreux secteurs industriels en raison de leur excellente dureté, de leur résistance à l'usure et de leur robustesse. Si vous débutez dans le monde du carbure de tungstène, billes de carbure de tungstène, ce guide vous aidera à comprendre ce qu'ils sont, comment ils sont fabriqués et où ils sont utilisés.

Qu'est-ce que le carbure de tungstène ?

Le carbure de tungstène est un composé chimique composé de tungstène (W) et de carbone (C). C'est l'un des matériaux les plus durs au monde, presque aussi dur que le diamant. De ce fait, il est souvent utilisé pour fabriquer des outils et des pièces devant résister à l'usure, à la chaleur et à la pression.

Lorsque ce matériau est façonné en boule, il devient une pièce haute performance pour des applications exigeantes telles que les roulements, les vannes, les appareils de mesure, etc.

Comment sont fabriquées les billes en carbure de tungstène ?

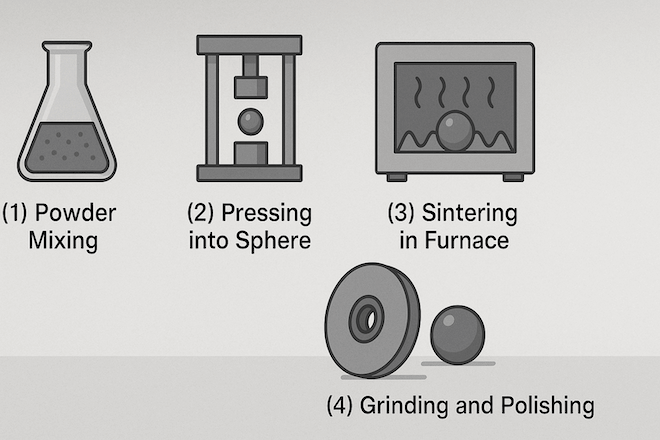

La production de billes de carbure de tungstène implique plusieurs étapes techniques :

Poudre Mélange

Des poudres fines de tungstène et de carbone sont mélangées.Presser pour mettre en forme

La poudre est pressée en forme de boule ronde à l'aide d'un moule.Frittage

La boule façonnée est chauffée dans un four à plus de 1400°C pour la durcir.Meulage et polissage

Après frittage, la bille est meulée et polie pour répondre aux exigences de taille et de surface.

Ces étapes garantissent que les balles finales sont solides, lisses et précises.

Principales propriétés des billes de carbure de tungstène

Les billes de carbure de tungstène sont populaires en raison de leurs propriétés uniques :

Extrême Dureté – Beaucoup plus dur que l’acier.

Haut Résistance à l'usure – Ils durent plus longtemps sous frottement.

Excellent Résistance à la corrosion – Ils résistent à la rouille et aux produits chimiques.

Haut Densité – Ils sont très lourds et solides.

Bien Stabilité thermique – Ils fonctionnent bien à des températures élevées.

Serré Tolérance – Ils peuvent être produits avec des dimensions très précises.

Ces qualités les rendent idéales pour une utilisation à long terme, même dans des environnements difficiles.

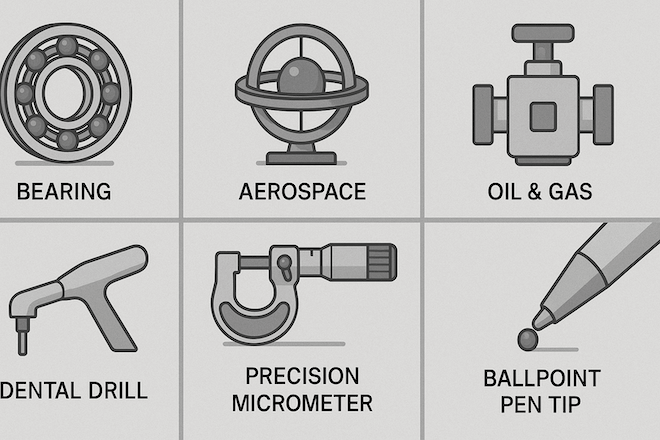

Où sont utilisées les billes de carbure de tungstène ?

Les billes de carbure de tungstène sont utilisées dans de nombreux domaines. En voici quelques exemples :

| Industrie | Application |

|---|---|

| Roulements | Pour pièces mécaniques à grande vitesse et à forte charge |

| Aérospatial | Dans les gyroscopes et les systèmes de navigation |

| Pétrole et gaz | Pour vannes et outils de mesure |

| Dispositifs médicaux | Dans les forets dentaires et les pièces de précision |

| Machines industrielles | Dans les vis à billes, les glissières et les outils de mesure |

| Stylos à encre | Comme les pointes de bille dans les stylos à bille |

Quel que soit le secteur d’activité, les billes en carbure de tungstène sont utilisées partout où la précision et la durabilité sont importantes.

Billes en carbure de tungstène vs. billes en acier

Vous vous demandez peut-être pourquoi on choisirait des billes en carbure de tungstène plutôt que des billes en acier classiques. Voici une comparaison simple :

| Fonctionnalité | Billes en carbure de tungstène | Billes d'acier |

|---|---|---|

| Dureté | Très élevé | Moyen |

| Résistance à l'usure | Excellent | Bien |

| Coût | Plus haut | Inférieur |

| Poids | Plus lourd | Plus léger |

| Durée de vie | Plus long | Plus court |

Si vous avez besoin de pièces durables et performantes, billes de carbure de tungstène sont le meilleur choix.

Tailles et tolérances courantes

Les billes en carbure de tungstène sont disponibles en plusieurs tailles. Les diamètres courants vont de 0,5 mm à 50 mm. Elles peuvent également être fabriquées avec différents degrés de tolérance, ce qui indique la précision de la taille.

| Plage de diamètres | Utilisation typique |

|---|---|

| 0,5 mm – 3 mm | Stylos, outils médicaux |

| 3 mm – 10 mm | Roulements, outils de mesure |

| 10 mm – 50 mm | Vannes, composants pour le pétrole et le gaz |

La tolérance peut être aussi stricte que ±0,002 mm, selon vos besoins.

Comment choisir la bonne bille en carbure de tungstène

Voici quelques conseils pour sélectionner la meilleure balle en fonction de vos besoins :

Connaissez votre application

Choisissez en fonction de l’endroit et de la manière dont le ballon sera utilisé.Sélectionnez la bonne note

Certains niveaux sont plus difficiles, d'autres plus exigeants. Choisissez celui qui convient le mieux à votre travail.Vérifiez la taille et la tolérance

Assurez-vous que la balle s'adapte parfaitement à votre équipement.Demandez à votre fournisseur

Un fournisseur de confiance peut vous guider vers la meilleure option.

Conclusion

Les billes en carbure de tungstène sont des outils puissants dans de nombreux secteurs. Elles offrent une dureté, une résistance à l'usure et une durée de vie supérieures. Que vous travailliez dans l'ingénierie, la fabrication, le pétrole et le gaz ou les dispositifs médicaux, ces billes offrent des performances fiables.

Si vous recherchez des billes de carbure de tungstène de haute qualité, assurez-vous de travailler avec un fournisseur professionnel qui peut proposer des tailles personnalisées, des tolérances serrées et des conseils d'experts.