Le aérospatial and defense industries demand absolute reliability. Every component—from turbines and landing gear to missile actuators—must perform perfectly under extreme stress, vibration, and temperature.

In these sectors, failure is not an option. A single worn bearing or misaligned shaft can cause system damage or mission failure.

That’s why bagues en carbure de tungstène have become essential in aerospace and defense engineering.

They provide unmatched résistance à l'usure, strength, and stability—helping critical systems perform smoothly even under the toughest operating conditions.

This article explains why aerospace and defense manufacturers rely on tungsten carbide bushings, their unique benefits, and how they outperform conventional materials.

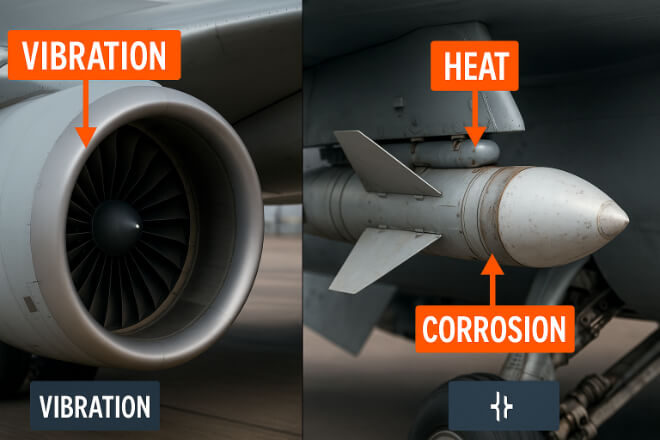

Demands of Aerospace and Defense Applications

Aerospace and defense systems face some of the harshest mechanical and environmental conditions.

Bushings, bearings, and sleeves in these systems must function flawlessly in vacuum, high-altitude, or corrosive conditions, often with limited lubrication.

Key Challenges:

Extreme temperatures – from -60°C in flight to over 600°C in turbines.

Vibration and load stress – caused by engines, landing, and aerodynamic forces.

Limited lubrication – due to sealed or weight-restricted systems.

High precision requirements – minimal clearance tolerances for rotating parts.

Corrosive exposure – from hydraulic fluids, jet fuel, or salt-laden air.

Standard steel or bronze bushings often fail to meet these demands. bagues en carbure de tungstène, however, can maintain dimensional stability and résistance à l'usure under all these conditions.

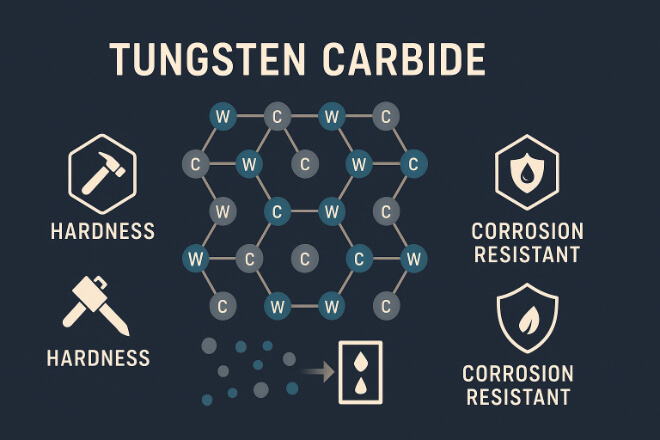

Material Advantages of Tungsten Carbide

Tungsten carbide (WC) is made by combining tungsten and carbon with a metallic binder, usually nickel or cobalt.

It has the dureté of a ceramic but the strength of a metal, making it a unique material for aérospatial candidatures.

Key Mechanical Properties:

Hardness: Up to 92 HRA, far exceeding tool steel.

Compressive Strength: Above 4000 MPa.

Melting Point: Over 2800°C (5070°F).

Low Thermal Expansion: Ensures precise fit even under heat.

Résistance à la corrosion: Withstands hydraulic fluids, fuels, and moisture.

Tungsten carbide bushings retain strength even at elevated temperatures and provide superior load-bearing capability in compact aerospace assemblies.

Comparison with Other Aerospace Bushing Materials

| Matériel | Dureté (HRA) | Température maximale (°C) | Résistance à la corrosion | Utilisation typique |

|---|---|---|---|---|

| Bronze | 65–70 | 250 | Faible | Landing gear, low-load systems |

| Acier inoxydable | 75–80 | 400 | Bien | Hydraulic actuators |

| Carbure de tungstène | 88–92 | 800+ | Excellent | Engines, turbines, flight actuators |

The table clearly shows that tungsten carbide outperforms other metals in all major categories critical to aerospace applications.

Aerospace Applications of Tungsten Carbide Bushings

| Composant | Operating Conditions | Purpose of Bushing |

|---|---|---|

| Turbine Engine | High temperature, vibration | Reduces friction and stabilizes shafts |

| Landing Gear | Impact load and dust exposure | Prevents wear on pivot joints |

| Flight Control Actuators | Limited lubrication, precision fit | Ensures smooth control motion |

Tungsten carbide bushings are used in both rotating and oscillating parts of aircraft systems where precision and reliability are vital.

Defense Applications of Tungsten Carbide Bushings

| Defense Equipment | Environment | Role of Bushing |

|---|---|---|

| Missile Guidance Systems | High vibration, limited space | Supports miniature rotating assemblies |

| Armored Vehicle Suspension | Shock, dust, and mud | Extends service life under heavy load |

| Naval Systems | Saltwater and vibration | Prevents corrosion and galling |

In defense systems, reliability under extreme impact and variable conditions is crucial.

Tungsten carbide bushings provide long service life with minimal maintenance, even under shock and vibration.

Binder and Microstructure Choices

| Liant | Performance Feature | Best Application |

|---|---|---|

| Cobalt (Co) | High impact strength and fatigue resistance | Landing gear, actuators |

| Nickel (Ni) | Excellent corrosion resistance in humid or saline air | Naval and defense systems |

Fine-grain tungsten carbide with carefully chosen binders provides higher dureté and improved fatigue life—important for long missions and harsh environments.

Benefits for Aerospace and Defense Engineers

Using tungsten carbide bushings brings several critical benefits to design and maintenance teams:

Reduced wear and vibration in high-speed or high-load applications.

Improved dimensional stability over a wide temperature range.

Longer service intervals and lower maintenance cost.

Reliable performance in zero-lubrication systems.

Increased safety and mission reliability.

These advantages make tungsten carbide bushings not just a component upgrade—but a strategic reliability investment.

Exemple concret

| Application | Previous Material | Old Life Cycle | New Life Cycle (Tungsten Carbide) | Improvement |

|---|---|---|---|---|

| Flight Control Actuator | Acier inoxydable | 2,000 hours | 6,000 hours | +200% |

| Landing Gear Pivot | Bronze | 1 year | 4 ans | +300% |

Aerospace OEMs have documented up to three times longer service life when switching from bronze or steel bushings to tungsten carbide in critical moving assemblies.

Conclusion

In aerospace and defense, reliability is mission success.

Tungsten carbide bushings deliver the strength, durability, and precision required in systems that cannot fail.

From turbine engines to missile control systems, they ensure smooth motion, reduced wear, and extended service life—even under vibration, pressure, and extreme temperature.

For decision-makers, investing in tungsten carbide bushings is not just a technical choice—it’s a commitment to performance, safety, and long-term efficiency.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.