Tungsten carbide tips are widely regarded as some of the best tools for demanding industrial applications.

Known for their superior dureté, résistance à l'usure, and ability to withstand high temperatures, tungsten carbide tips often come with a higher upfront cost. However, the real value of these tools becomes clear when considering their long-term benefits.

In this blog, we will explore why investing in tungsten carbide tips is a wise decision that can offer significant savings and performance improvements over time.

Tungsten Carbide Tips: A High-Performance Solution

Tungsten carbide is one of the hardest materials known, making it the ideal choice for cutting, drilling, and machining tools.

Its exceptional properties make tungsten carbide tips more durable and longer-lasting than tools made from softer materials like high-speed steel (HSS) or ceramics.

1). What Makes Tungsten Carbide Tips Different?

Dureté: Tungsten carbide tips are incredibly hard, allowing them to maintain sharpness and precision longer than other tools.

Résistance à l'usure: Carbide tips resist wear from abrasive materials, meaning they stay effective in tough working conditions, reducing the frequency of tool replacements.

Résistance à la chaleur: Tungsten carbide can withstand high temperatures without losing its hardness, making it ideal for operations that generate heat.

These properties make tungsten carbide tips a long-term solution for demanding industrial applications.

The Long-Term Cost Benefits of Tungsten Carbide Tips

While tungsten carbide tips often come with a higher upfront cost, their durability and long lifespan make them a cost-effective choice in the long run. Here’s how investing in tungsten carbide tips can save money over time:

1). Fewer Replacements

One of the main advantages of tungsten carbide tips is their long lifespan.

These tips last much longer than those made from materials like HSS or ceramic. While you may pay more initially, fewer replacements mean lower costs over time.

2). Reduced Downtime

Because carbide tips last longer, there is less downtime in the manufacturing process for tool replacements. This leads to increased productivity and fewer disruptions in operations.

3). Lower Maintenance Costs

Tungsten carbide tips require less frequent sharpening and maintenance compared to other tools.

This reduces the costs associated with tool upkeep and extends the intervals between required maintenance.

Improved Productivity and Performance

Tungsten carbide tips provide superior cutting performance, which translates into better overall productivity and efficiency in the manufacturing process.

1). Higher Cutting Speed

Tungsten carbide tips can cut through materials at higher speeds without losing effectiveness. This increased cutting speed means more work can be done in less time, improving overall production rates.

2). Consistent Performance

Carbide tips maintain their sharpness longer, ensuring consistent performance throughout their lifespan.

This consistency reduces the chances of production errors, ensuring high-quality results in each operation.

3). Better Surface Finish

The precision and sharpness of tungsten carbide tips result in smoother cuts and better surface finishes.

This is especially important in industries that require high-quality outputs, such as automobile et aérospatial fabrication.

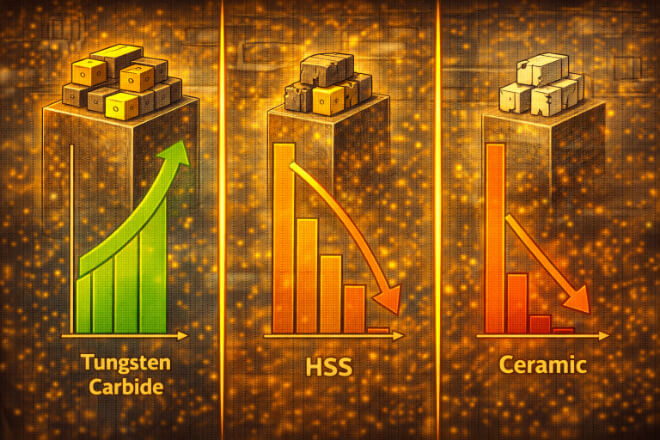

The Durability Factor: Tungsten Carbide vs. Other Materials

When comparing tungsten carbide tips to other materials like HSS and ceramic, their durability stands out as a key benefit. Let’s take a closer look:

1). Tungsten Carbide vs. High-Speed Steel (HSS)

HSS tools are commonly used in manufacturing but wear out quickly compared to tungsten carbide tips. Tungsten carbide tips can last 5–10 times longer than HSS tools, depending on the application.

2). Tungsten Carbide vs. Ceramic Tips

While ceramic tools are known for their hardness, they are often more brittle than tungsten carbide.

This brittleness means ceramic tips are more prone to breaking or chipping, especially under high-impact conditions.

Tungsten carbide, on the other hand, offers both hardness and dureté, making it more versatile and reliable over time.

The durability of tungsten carbide tips leads to a better return on investment, especially in high-demand applications.

Total Cost of Ownership (TCO) for Tungsten Carbide Tips

The Total Cost of Ownership (TCO) is a comprehensive metric that accounts for all costs associated with a tool throughout its lifecycle, including purchase price, maintenance, and replacement costs.

When evaluating TCO, tungsten carbide tips typically offer a more cost-effective solution compared to other materials.

1). Initial Investment vs. Long-Term Savings

While tungsten carbide tips are more expensive upfront, their long lifespan and low maintenance costs result in significant savings over time.

In high-volume or high-stress applications, the return on investment (ROI) is often substantial.

2). Tool Life and Reduced Replacement Costs

Since tungsten carbide tips last longer, the cost per unit over time is lower. Fewer replacements and less frequent maintenance make carbide tips a more economical choice in the long run.

3). Operational Efficiency

The higher cutting speed and efficiency of carbide tips result in improved production rates, further justifying the investment.

With carbide tips, businesses can achieve higher throughput and less downtime, leading to increased overall efficiency.

Why Tungsten Carbide Tips Are a Long-Term Benefit for Manufacturers

Investing in tungsten carbide tips can be a smart decision for businesses looking to improve productivity and reduce long-term costs.

While the initial investment may be higher, the advantages in durability, performance, and cost-effectiveness make tungsten carbide tips an excellent choice for many manufacturing operations.

1). Less Frequent Tool Changes

Carbide tips provide consistent performance for a longer time, which means fewer tool changes are required. This reduces tool costs and minimizes downtime.

2). Reduced Operational Disruptions

By using high-quality tungsten carbide tips, manufacturers can reduce disruptions caused by tool failures, ensuring smoother operations and more reliable output.

3). Increased Profitability

The long lifespan, reduced maintenance needs, and increased productivity lead to higher profitability.

Businesses that use tungsten carbide tips see a clear return on investment in the form of cost savings and improved efficiency.

Conclusion

Tungsten carbide tips offer significant long-term benefits for manufacturers.

While the initial cost may be higher than alternatives like HSS or ceramic tips, the durability, extended lifespan, and lower maintenance costs make them a wise investment.

By improving productivity, reducing downtime, and lowering total cost of ownership, tungsten carbide tips help businesses increase efficiency and achieve a better return on investment over time.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.