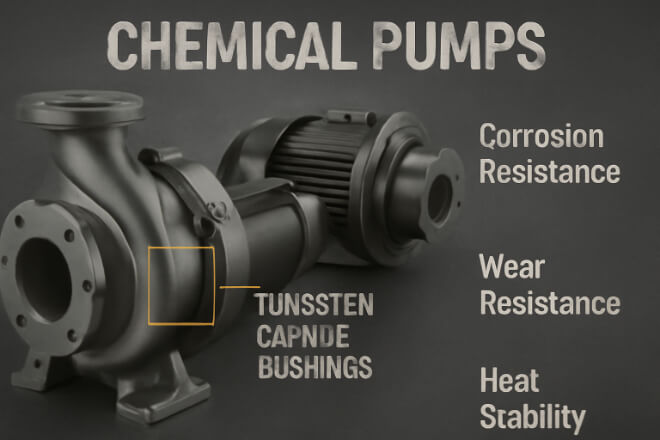

Chemical pumps are crucial in many industries, from petrochemicals to pharmaceuticals, where they handle corrosive, abrasive, and high-temperature fluids.

The materials used in these pumps need to be tough, résistant à l'usure, and able to withstand harsh chemical environments.

bagues en carbure de tungstène have become the preferred choice for chemical pumps due to their exceptional properties.

In this article, we’ll explore why tungsten carbide bushings are ideal for chemical pumps and how they contribute to the efficiency and longevity of these critical systems.

Why Tungsten Carbide Bushings Are Ideal for Chemical Pumps

Chemical pumps are constantly exposed to aggressive fluids, extreme temperatures, and mechanical stress.

bagues en carbure de tungstène stand out as the material of choice for such demanding applications due to several key properties:

Résistance à la corrosion: Tungsten carbide is highly resistant to corrosion, even in the presence of harsh chemicals commonly found in chemical pumps. This ensures the longevity of the bushings and reduces maintenance costs.

Haut Résistance à l'usure: Le dureté of tungsten carbide makes it resistant to abrasion, which is essential in chemical pumps that handle abrasive slurries or viscous fluids.

Heat Resistance: Tungsten carbide maintains its strength and integrity at high temperatures, preventing failure due to thermal degradation in chemical pumps.

Dimensional Stability: Tungsten carbide does not deform or lose its shape easily, even under high pressure and continuous operation.

These properties make tungsten carbide bushings perfect for pumps that need to operate reliably and efficiently in chemical processing environments.

Key Benefits of Tungsten Carbide Bushings in Chemical Pumps

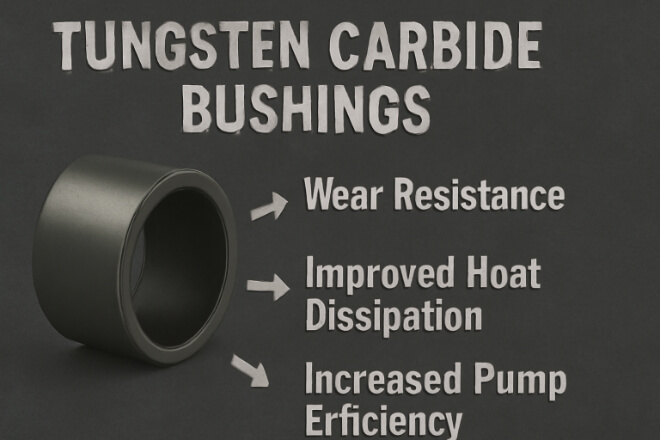

1). Superior Wear Resistance

Chemical pumps are exposed to abrasives and solids that can cause rapid wear in other materials.

Tungsten carbide, with its dureté and density, offers superior résistance à l'usure, ensuring that the bushings last longer, even when exposed to abrasive liquids.

Example: In pumps handling slurries or particulate matter, tungsten carbide bushings help to reduce friction and wear, ensuring that the pump operates smoothly without frequent replacements.

2). Résistance à la corrosion in Aggressive Environments

Chemical pumps often handle fluids that are highly corrosive, such as acids, alkalis, and other aggressive chemicals.

Tungsten carbide’s resistance to corrosion makes it an ideal material for these applications.

It will not degrade when exposed to such harsh chemicals, ensuring the bushings remain functional and reliable.

Example: Tungsten carbide bushings used in pumps handling hydrochloric acid or sulfuric acid can withstand chemical exposure without corroding, providing reliable operation in critical systems.

3). High-Temperature Performance

Chemical pumps often operate in high-temperature environments, where conventional materials may fail.

Tungsten carbide can withstand temperatures up to 1,000°C, making it highly suitable for chemical pumps in high-heat applications, such as those used in petrochemical processing.

Example: In applications where chemical pumps are exposed to high-temperature fluids, tungsten carbide bushings maintain their performance, ensuring consistent pumping efficiency.

4). Reduced Maintenance and Downtime

By using tungsten carbide bushings, chemical pumps can experience reduced wear and tear, leading to less frequent breakdowns and less downtime for maintenance.

This reduces the total cost of ownership and increases the overall efficiency of the pump systems.

- Example: Tungsten carbide bushings in chemical pumps reduce the need for frequent replacements and repairs, allowing operators to keep systems running smoothly for longer periods.

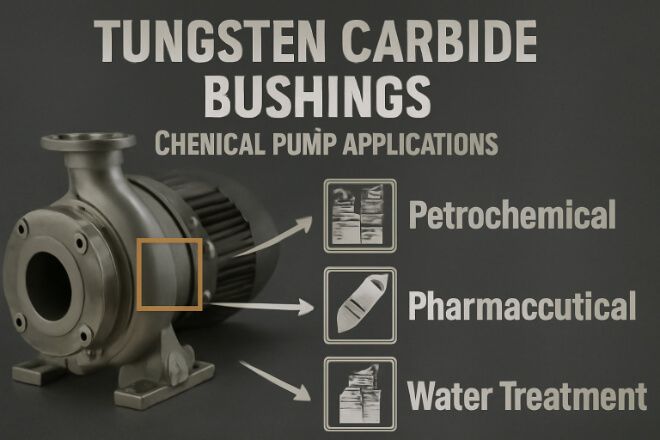

Applications of Tungsten Carbide Bushings in Chemical Pumps

Tungsten carbide bushings are widely used in a variety of chemical pump applications, including:

1). Petrochemical Industry

In petrochemical processing, pumps often handle aggressive chemicals and high temperatures.

Tungsten carbide bushings provide excellent performance in these harsh environments, preventing wear and ensuring the longevity of the equipment.

Example: Tungsten carbide bushings in petrochemical pumps that handle crude oil or natural gas liquids help to resist corrosion and wear, ensuring the pumps perform reliably.

2). Pharmaceutical Industry

Chemical pumps in the pharmaceutical industry require materials that are not only durable but also safe and clean.

Tungsten carbide’s résistance à la corrosion and ability to maintain dimensional stability make it an excellent choice for pharmaceutical pumps.

Example: Tungsten carbide bushings are used in pumps handling chemical solutions that must remain free of contamination, ensuring that the products remain safe and the pump performs efficiently.

3). Water Treatment

In water treatment plants, pumps handle a variety of chemical solutions used to purify and treat water.

Tungsten carbide bushings are used in these pumps to ensure longevity and reliability under constant exposure to chemicals and abrasive materials.

Example: Pumps in water treatment plants using chlorine or other chemicals benefit from tungsten carbide bushings, which prevent corrosion and reduce the risk of pump failure.

4). Mining and Mineral Processing

Chemical pumps in mining operations are exposed to abrasive slurries and harsh chemicals.

Tungsten carbide bushings offer the necessary wear resistance and corrosion protection to keep these pumps running smoothly in demanding conditions.

- Example: Tungsten carbide bushings are ideal for pumps handling slurry in mining operations, where the constant abrasion from solid materials can cause rapid wear on other materials.

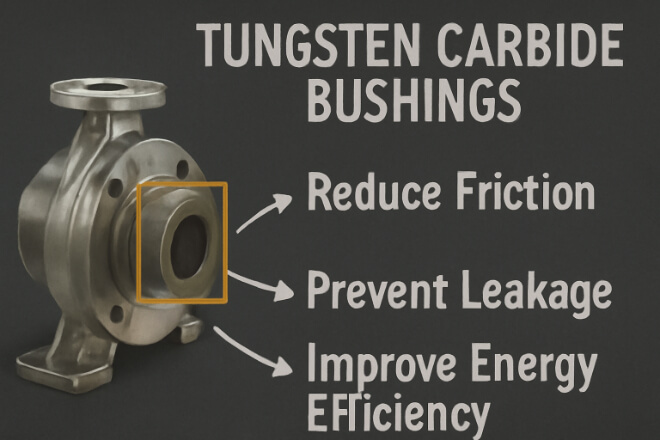

How Tungsten Carbide Bushings Improve Pump Efficiency

1). Improved Fluid Handling

bagues en carbure de tungstène help to reduce friction and wear, allowing chemical pumps to handle fluids more efficiently.

By ensuring smooth operation, the bushings help prevent issues like cavitation or leakage, which can lead to inefficiencies.

Example: In a high-pressure pump system, tungsten carbide bushings ensure that the pump operates at optimal efficiency, reducing energy consumption and preventing fluid leakage.

2). Consistent Performance

Tungsten carbide bushings maintain their strength and shape even under harsh conditions, ensuring that the pump operates at consistent speeds and capacities without degradation over time.

Example: In a high-demand pump system, the use of tungsten carbide bushings ensures that the pump operates efficiently and consistently, even under continuous use.

3). Energy Efficiency

By reducing friction and wear, tungsten carbide bushings help to maintain the pump’s efficiency, which can lead to lower energy consumption. This results in reduced operating costs over the long term.

- Example: Tungsten carbide bushings help to reduce frictional losses, improving the overall energy efficiency of chemical pumps and leading to cost savings.

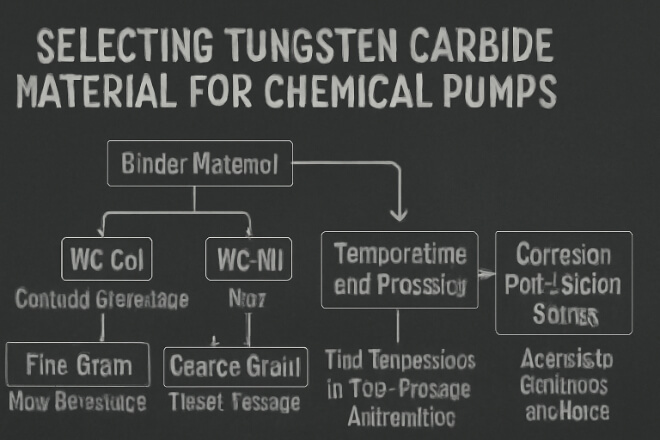

How to Choose the Right Tungsten Carbide Material for Chemical Pumps

When selecting tungsten carbide bushings for chemical pumps, several factors need to be considered:

1). Binder Material

The binder material, such as cobalt or nickel, affects the performance of the tungsten carbide bushings.

For chemical pumps exposed to corrosive environments, tungsten carbide with a nickel binder offers superior corrosion resistance.

2). Grain Size

The grain size of the tungsten carbide affects its dureté et résistance à l'usure.

Fine-grain tungsten carbide is preferred for high-precision applications, while coarse-grain tungsten carbide may be better for high-impact conditions.

3). Temperature and Pressure Conditions

Consider the temperature and pressure at which the pump operates. Tungsten carbide materials with higher temperature and pressure resistance should be selected for systems that operate in extreme conditions.

Conclusion

Tungsten carbide bushings are an essential component for chemical pumps, offering exceptional wear resistance, corrosion resistance, and high-temperature stability.

By using tungsten carbide bushings, industries can improve the efficiency, reliability, and longevity of their pumps, reducing maintenance costs and improving overall system performance.

Si vous souhaitez en savoir plus sur une entreprise, n'hésitez pas à Contactez-nous.