What is Fracture Toughness?

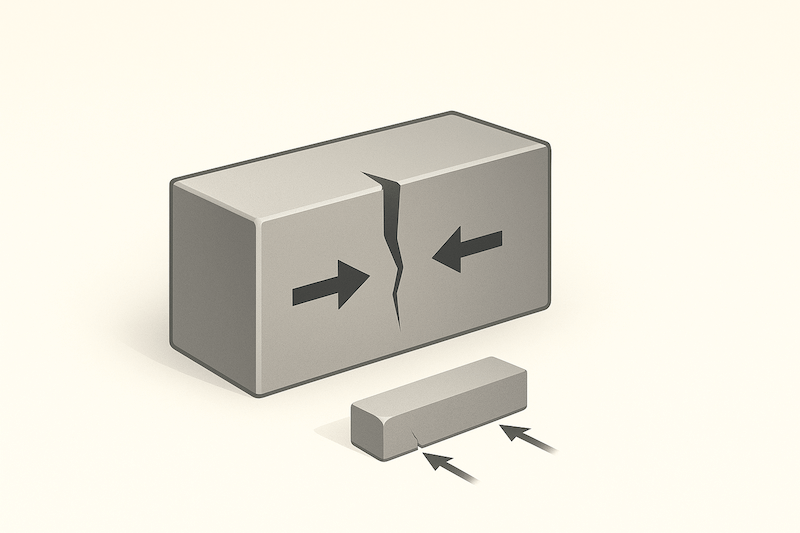

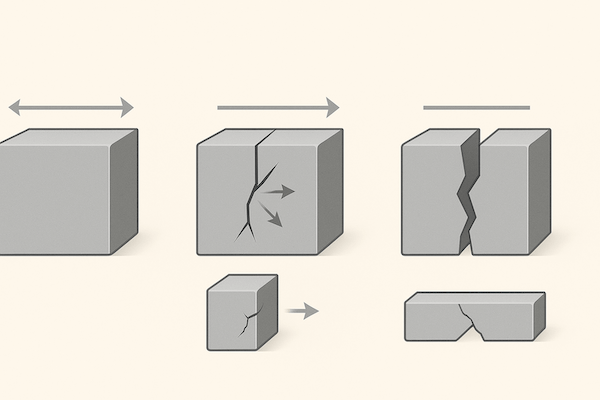

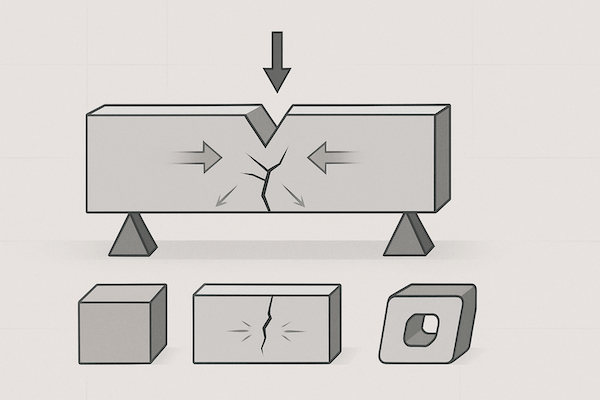

Fracture toughness is a material’s ability to resist the propagation of cracks. It quantifies how well a material can withstand stress in the presence of a flaw or defect, and it is especially important in brittle materials.

Fracture toughness is typically denoted as K₁c and measured in MPa·√m. A higher K₁c value means the material can better resist catastrophic failure even when microscopic cracks exist.

Why is Fracture Toughness Important?

In real-world engineering, no material is flawless—microcracks, voids, or inclusions often exist due to machining, fatigue, or material limitations. If a material has low fracture toughness, these small flaws can grow under stress, quickly leading to brittle fracture.

Fracture toughness becomes a critical design parameter in tools that experience:

Impact or vibration

Rapid temperature fluctuations

Bending or torsional forces

Repeated mechanical cycles (fatigue)

The Role of Fracture Toughness in Tungsten Carbide

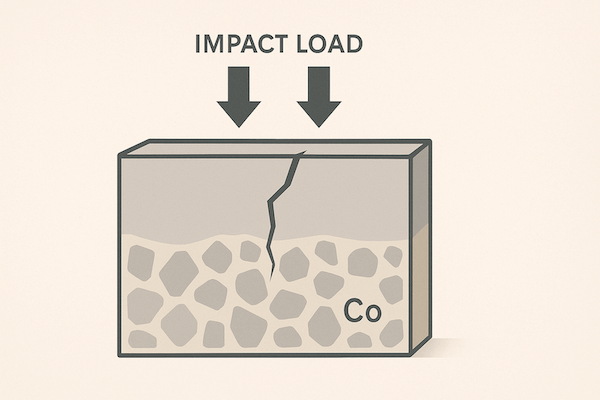

Tungsten carbide (WC), when combined with a metallic binder like cobalt (Co), forms cemented carbide—a hard, wear-resistant material used in cutting tools, mining picks, dies, and wear parts.

However, WC is inherently brittle, and its fracture toughness is lower than metals or polymers. This makes K₁c a key performance metric when designing tungsten carbide tools, especially in applications involving dynamic or impact loads.

Typical fracture toughness values for cemented carbide range between:

6 – 15 MPa·√m, depending on grain size, binder content, and microstructure.

Factors Affecting Fracture Toughness in Cemented Carbide

Several factors influence the fracture toughness of tungsten carbide tools:

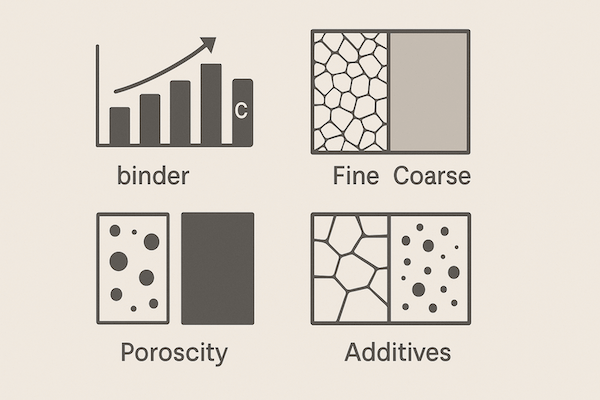

1. Cobalt Binder Content

More cobalt generally increases fracture toughness, though it may reduce hardness. For example:

YG20 (20% Co) has higher K₁c but lower wear resistance

YG6 (6% Co) has high hardness but lower K₁c

2. Grain Size of WC

Fine grains provide better strength, while slightly coarser grains can sometimes improve K₁c by preventing microcrack coalescence.

3. Additives and Inhibitors

Additions like Cr₃C₂ or VC improve both toughness and sintering density, enhancing fracture resistance.

4. Porosity and Defects

Internal voids reduce fracture toughness. High-density sintering and clean powder metallurgy are essential.

5. Coatings (like TiAlN or DLC)

While coatings don’t directly affect K₁c, they can reduce crack initiation on tool surfaces.

Applications Where Fracture Toughness Matters Most

Fracture toughness is especially critical in:

Mining and construction tools (e.g., carbide drill bits, picks) – exposed to impact and shock

Punches and dies – resist crack growth from cyclic loading

Cutting inserts for cast iron – where interrupted cutting is common

Forming tools – subjected to bending stress or deflection

Wear parts with thin geometries – such as nozzles or small pins

Measuring Fracture Toughness

Fracture toughness in tungsten carbide is usually measured using methods such as:

Single-edge notched beam (SENB) test

Chevron notch technique

Indentation fracture method (for small samples)

These tests introduce controlled cracks to evaluate how the material behaves under critical stress conditions.

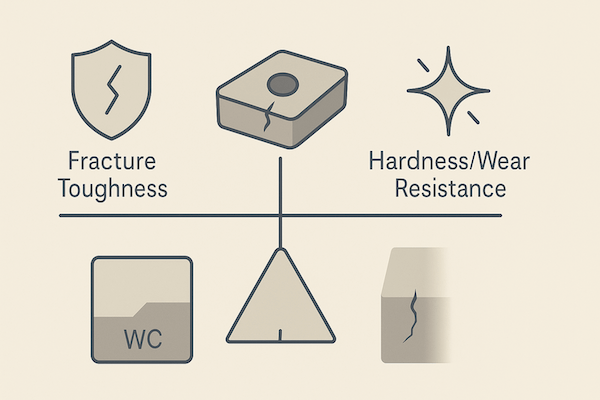

Balancing Fracture Toughness and Other Properties

While high fracture toughness is desirable, it must be balanced with:

Hardness – for wear resistance

Compressive strength – for heavy loading

Thermal stability – for high-speed cutting

Tool engineers must choose the right carbide grade to achieve the best performance in each specific application.

Conclusion

Fracture toughness is a crucial property that determines the reliability and durability of tungsten carbide tools, especially in harsh or impact-prone environments. Understanding how it interacts with other material characteristics helps manufacturers select or develop carbide grades that resist crack propagation and extend tool life. In modern carbide design, K₁c is not just a number—it’s a guarantee against sudden failure.