In the world of machining and manufacturing, tungsten carbide cutting tools are trusted for their strength, durability, and performance.

Still, many professionals—especially decision-makers—have questions about how these tools work, when to use them, and how to get the best results.

In this guide, we’ll answer the most common questions using simple, clear language.

What Are Tungsten Carbide Cutting Tools?

Tungsten carbide cutting tools are made from a hard, dense material that is a combination of tungsten and carbon. They are much harder than steel and stay sharp for longer.

These tools are used in CNC machining, metal cutting, and drilling because they can handle high heat and hard materials without wearing out quickly.

What Makes Tungsten Carbide Better Than Other Tool Materials?

The main reason manufacturers choose tungsten carbide over high-speed steel (HSS) or ceramic is its superior hardness and heat resistance.

Carbide tools cut faster and last longer. They can also maintain sharp edges at higher temperatures, which means fewer tool changes and more uptime.

Advantages of tungsten carbide cutting tools:

Longer tool life

Higher cutting speeds

Better surface finish

Stronger edge retention

How Long Do Tungsten Carbide Cutting Tools Last?

Tool life depends on the material you’re cutting, machine speed, tool geometry, and whether the tool has a coating. In general, tungsten carbide tools last 2 to 10 times longer than HSS tools.

When used correctly with proper speeds, feeds, and coolant, carbide tools can run for many hours before needing replacement.

Tip: Use tool life monitoring systems or keep a simple log to track how long each tool performs in real conditions.

How Do I Know When to Replace a Carbide Tool?

Here are common signs it’s time to replace your tungsten carbide cutting tool:

Poor surface finish on the part

Strange noises or vibration during cutting

Tool shows visible wear, chips, or cracks

Increased cutting forces or heat

Tools no longer hold tight tolerances

Replacing a tool at the right time avoids damage to parts, machines, and downstream processes.

Can Tungsten Carbide Tools Be Re-Sharpened?

Yes! Many carbide tools—especially end mills, drills, and reamers—can be re-sharpened multiple times.

Regrinding saves money and reduces waste. However, not all tools are worth reconditioning. Check the remaining length and wear level before deciding.

For best results, use a professional tool regrinding service. They use high-precision grinders to restore edge geometry.

What Industries Use Tungsten Carbide Tools the Most?

Tungsten carbide cutting tools are used across many industries, including:

Aerospace: For machining titanium, Inconel, and composites

Automotive: Engine parts, brake components, and chassis machining

Oil and gas: Valve bodies, drilling components, pipe threading

Medical: Precision tools for surgical instruments and implants

Tool and die: Mold making and hardened steel cutting

They’re also common in woodworking, mining, and general CNC job shops.

Are All Carbide Tools the Same Quality?

Not at all. There are big differences in:

Grain size of the tungsten carbide powder (fine-grain lasts longer)

Cobalt content, which affects toughness

Manufacturing process and sintering quality

Geometry and precision of grinding

Coating technology

What Coatings Are Used on Carbide Cutting Tools?

Coatings improve tool performance by reducing friction, heat, and wear. Common coatings include:

TiN (Titanium Nitride): good general-purpose coating

TiAlN / AlTiN (Titanium Aluminum Nitride): strong heat resistance for steel

DLC (Diamond-Like Carbon): low friction, ideal for aluminum and plastics

CVD Diamond: for very hard or abrasive materials like carbon fiber

Choose coatings based on your application. A coated tool may cost more but usually lasts much longer and cuts more cleanly.

How Should I Store and Handle Carbide Tools?

Carbide tools are hard but can be brittle if dropped or mishandled. Store them in padded trays or cases. Keep cutting edges away from each other to avoid chipping.

Tips:

Use tool racks or labeled drawers

Avoid moisture and extreme temperature changes

Clean tools before returning them to storage

Do not mix coated and uncoated tools

Handling carbide tools carefully helps you protect your investment and avoid downtime.

What Should I Look For in a Carbide Tool Supplier?

A good supplier offers more than just a catalog of tools. Look for:

Quality assurance and testing

Wide selection of grades and geometries

Custom tool design or modification

Fast and reliable delivery

Technical support for tool selection and machining parameters

Can I Use Carbide Tools on All Machines?

Most carbide tools are designed for CNC machines and rigid setups. They work best on machines with:

High spindle speeds

Stable fixturing

Correct feed rates and cooling

Some manual machines or older lathes may not be rigid enough to use carbide tools effectively. Always match the tool to the machine and the material.

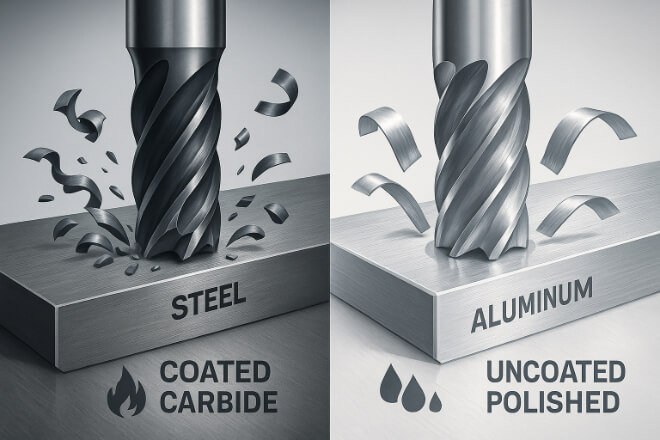

Are Coated Tools Always Better?

Not always. While coatings improve wear resistance and reduce heat, they aren’t ideal for every job.

For example, in aluminum cutting, polished uncoated tools often work better than coated ones.

Choose coated tools when:

Cutting hard or abrasive materials

Running high-speed dry machining

You need longer tool life between changes

In some cases, an uncoated carbide tool gives better chip evacuation or finish—especially with soft materials.

How Much Do Tungsten Carbide Tools Cost?

Carbide tools cost more upfront than HSS tools, but they deliver better value over time. Price varies depending on:

Tool type (end mill, drill, insert, etc.)

Size and length

Coating

Brand and quality grade

In many cases, spending 20–30% more on a high-quality tool saves money in the long run due to fewer tool changes, lower scrap, and better machining speed.

Final Thoughts

Tungsten carbide cutting tools are essential for modern machining. Whether you’re cutting steel, aluminum, composites, or titanium, carbide tools help you machine faster, reduce downtime, and keep part quality high.

By understanding how these tools work and how to maintain them, you can make smarter purchasing and usage decisions for your operation.

If you’re looking for reliable, high-performance carbide tools, visit Retopz —where quality, consistency, and support come standard.