When companies choose tungsten carbide wear parts, they often focus on hardness, toughness, and cost. But one factor is often overlooked: grain size.

The size of the tungsten carbide grains in the microstructure has a direct effect on the wear resistance, toughness, and lifetime of the part.

For decision-makers in industries like mining, oil and gas, metalworking, and manufacturing, understanding grain size is important. It helps in choosing the right grade of carbide for each application, balancing performance with cost.

This article explains how grain size influences carbide wear performance, why it matters, and how companies can use this knowledge to make better purchasing decisions.

What Is Grain Size in Carbide Materials?

Tungsten carbide is made by combining hard carbide grains with a metal binder (usually cobalt or nickel).

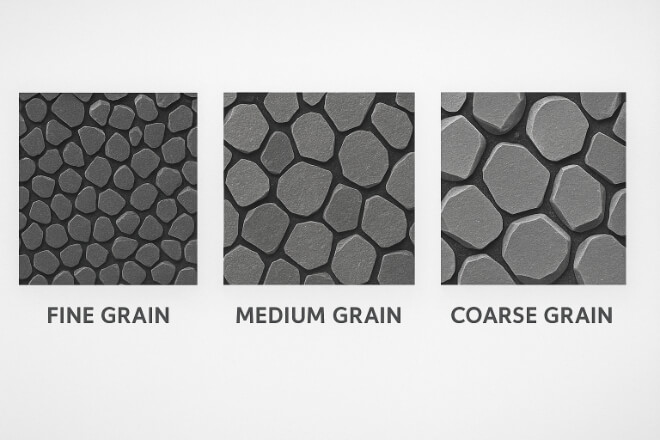

The grain size refers to how large or small these carbide particles are in the microstructure.

Fine-grain carbide: Grains are very small, usually less than 1 micron.

Medium-grain carbide: Grains between 1–3 microns.

Coarse-grain carbide: Grains larger than 3 microns.

Controlling grain size during manufacturing allows engineers to design carbide grades with specific properties suited for different uses.

Why Grain Size Matters for Wear Performance

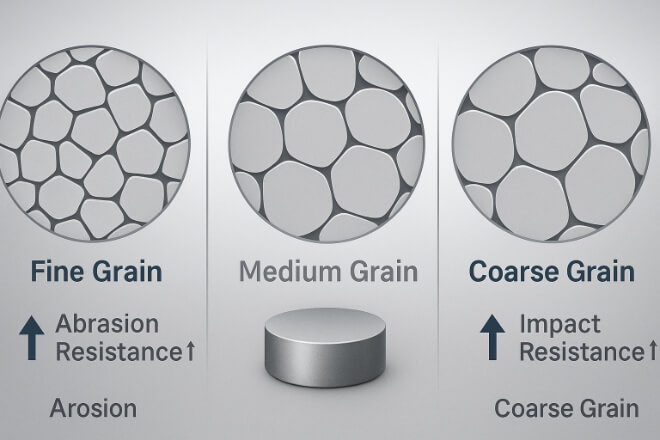

Grain size affects the balance between hardness and toughness:

Fine-grain carbide is harder and more resistant to abrasive wear.

Coarse-grain carbide is tougher and less likely to crack under heavy impact.

Medium-grain carbide provides a balance between both.

This means grain size is not just a technical detail—it directly impacts how long a part will last and how much value it delivers to the company.

Fine-Grain Carbide: High Wear Resistance

Fine-grain carbide has very small particles tightly packed together.

1). Advantages:

High hardness.

Excellent resistance to abrasive wear.

Can achieve smoother surface finishes.

Suitable for precision tools like cutting inserts, drills, and wear-resistant nozzles.

2). Limitations:

Less toughness, more brittle under sudden impact.

Higher production cost compared to coarse grades.

Fine-grain carbide is best when abrasive wear resistance is more important than impact strength.

Coarse-Grain Carbide: High Toughness

Coarse-grain carbide has larger particles, which increases toughness.

1). Advantages:

High resistance to cracking under impact.

Performs well in heavy-duty, shock-loaded applications.

Lower production costs.

2). Limitations:

Lower hardness compared to fine-grain carbide.

Wears faster in abrasive environments.

Coarse-grain carbide is ideal for mining picks, construction tools, and drilling equipment where impact loads are very high.

Medium-Grain Carbide: Balanced Performance

Medium-grain carbide combines the benefits of both fine and coarse grades.

1). Advantages:

Flexible for many industrial applications.

Cost-effective choice for companies that need performance without extreme specialization.

2). Limitations:

Not the best option for extreme cases of either abrasion or impact.

Medium-grain carbide is often used for general-purpose wear parts, such as bushings, sleeves, and valve components.

Grain Growth Control in Manufacturing

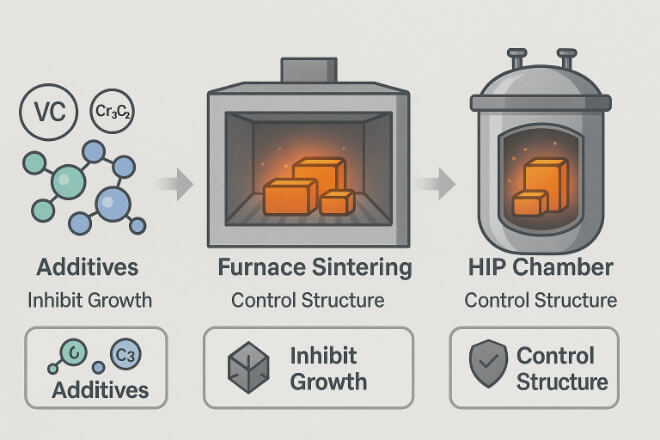

The grain size of carbide does not just “happen.” It is carefully controlled during production using additives and process adjustments.

Methods include:

Grain Growth Inhibitors: Small amounts of vanadium carbide (VC) or chromium carbide (Cr₃C₂) are added to keep grains fine.

Sintering Temperature and Time: Higher heat or longer sintering can make grains grow larger.

HIP (Hot Isostatic Pressing): Helps improve density while controlling grain structure.

By controlling grain size, manufacturers can design carbide grades tailored to specific industries and needs.

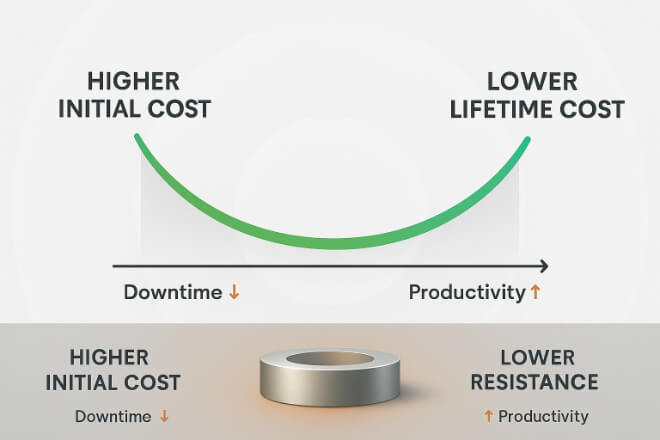

Cost and ROI of Choosing the Right Grain Size

Selecting the right carbide grain size has clear cost benefits:

Fewer replacements: Right grain size means parts last longer in specific conditions.

Lower downtime: Machines run more reliably with fewer failures.

Higher productivity: Performance matches application needs.

Better ROI: Initial cost is balanced by longer service life and fewer disruptions.

Decision-makers who consider grain size when buying carbide parts often see lower total costs over time.

Industry Applications of Different Grain Sizes

Different industries benefit from different grain sizes:

Mining and Construction: Coarse-grain carbide for tools exposed to heavy impact.

Metalworking: Fine-grain carbide for cutting inserts and end mills.

Oil and Gas: Medium-grain carbide for seal rings, nozzles, and valve parts.

Woodworking and Paper: Fine-grain carbide for sharp, long-lasting blades.

Aerospace and Automotive: Fine to medium-grain carbide for precision and durability.

Environmental and Sustainability Factors

Choosing the right grain size also helps the environment:

Less waste: Longer-lasting tools mean fewer replacements.

Energy efficiency: Machines use less power when tools cut effectively.

Recycling: Carbide with different grain sizes can still be recycled and reused.

For companies focused on sustainability, grain size optimization is another way to reduce environmental impact while improving performance.

Choosing the Right Supplier for Carbide Wear Parts

Not all suppliers control grain size with the same quality. When selecting a supplier, decision-makers should check for:

Advanced R&D and manufacturing technology.

Proven expertise in grain size control.

ISO certifications and quality assurance.

Ability to provide custom carbide grades.

A strong supplier ensures the right grain size for each application, maximizing performance and cost efficiency.

Conclusion

Grain size has a major impact on the wear performance of carbide parts. Fine grains deliver higher wear resistance, coarse grains provide toughness, and medium grains balance both.

By understanding and choosing the right grain size, companies can reduce downtime, improve productivity, and save costs.

For industries where reliability and ROI are critical, working with a supplier that understands grain size effects is the key to success.

If you want to know more details about any company, please feel free to contact us.