Seal rings are small but critical parts in pumps, compressors, turbines, and marine systems. The right choice of seal ring material can mean the difference between smooth operation and costly downtime.

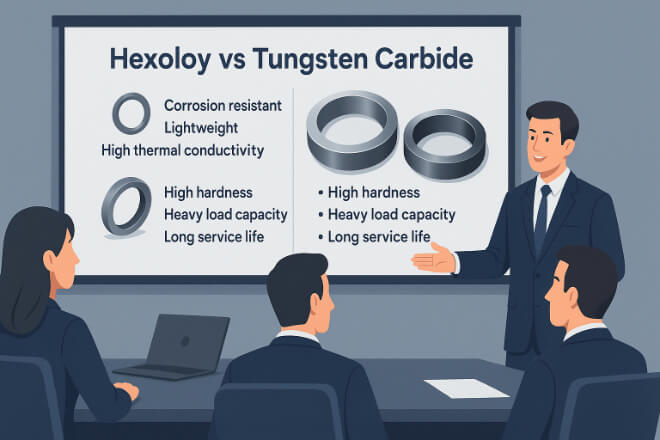

Among the many options, Hexoloy (a type of sintered silicon carbide) and tungsten carbide are two of the most commonly used.

Both materials are strong, durable, and suitable for high-demand industries. But they are not the same. Each has strengths and weaknesses that make it better for certain applications.

This article compares Hexoloy vs tungsten carbide seal rings, helping decision-makers choose the right option for their systems.

What Is Hexoloy?

Hexoloy is a trademarked form of sintered silicon carbide. It is a ceramic material known for:

Extreme hardness

Light weight compared to metals

High corrosion resistance (excellent against seawater and chemicals)

Thermal conductivity for spreading heat

Because of these properties, Hexoloy is used in marine pumps, chemical equipment, and high-temperature applications.

What Is Tungsten Carbide?

Tungsten carbide is a compound of tungsten and carbon, usually bonded with cobalt or nickel. It is famous for:

Very high hardness (close to diamond)

Outstanding wear resistance

High compressive strength

Good toughness against mechanical shock

Recyclability

This makes tungsten carbide ideal for power generation, oil and gas, and heavy-duty marine equipment, where loads and pressure are extreme.

Strengths of Hexoloy Seal Rings

Superior Corrosion Resistance

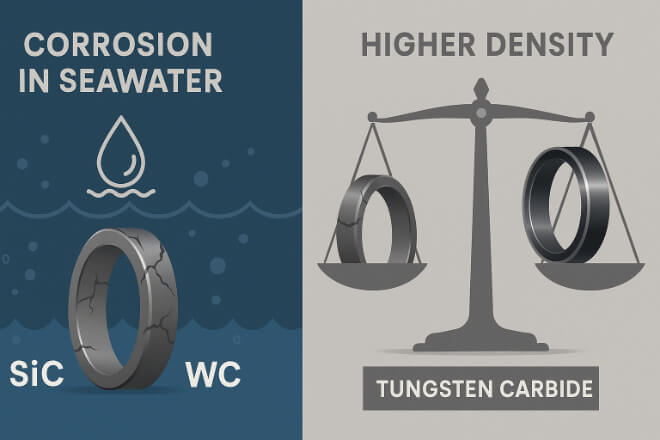

Hexoloy resists acids, alkalis, and seawater better than tungsten carbide. This makes it the best choice for aggressive chemical environments.

Lightweight Material

Its low density reduces equipment weight, which can improve energy efficiency in pumps and marine systems.

Thermal Conductivity

Hexoloy spreads heat evenly, avoiding hot spots and improving stability under high temperatures.

Chemical Compatibility

It performs well in environments with harsh fluids that may attack metallic binders.

Strengths of Tungsten Carbide Seal Rings

1). Higher Toughness

Tungsten carbide is less brittle than Hexoloy. It can handle mechanical shock, vibration, and sudden pressure changes better.

2). Heavy Load Capacity

Its compressive strength allows it to withstand very high loads without cracking, making it more reliable in turbines and compressors.

3). Long Service Life

Because of its wear resistance, tungsten carbide lasts longer in abrasive conditions like slurry pumps.

4). Recyclability

Unlike many ceramics, tungsten carbide can be collected and recycled, adding sustainability benefits.

Weaknesses of Hexoloy

Brittle Nature – Cracks more easily under impact or sudden pressure changes.

Lower Toughness – Cannot handle high mechanical shock as well as tungsten carbide.

Limited Load Capacity – Not the best for heavy-duty, high-pressure applications.

Weaknesses of Tungsten Carbide

Lower Corrosion Resistance – Cobalt-bonded grades are more vulnerable in seawater or chemical-rich environments.

Heavier Material – Higher density adds weight to equipment.

Higher Upfront Cost – More expensive than some other materials, though cost is balanced by long service life.

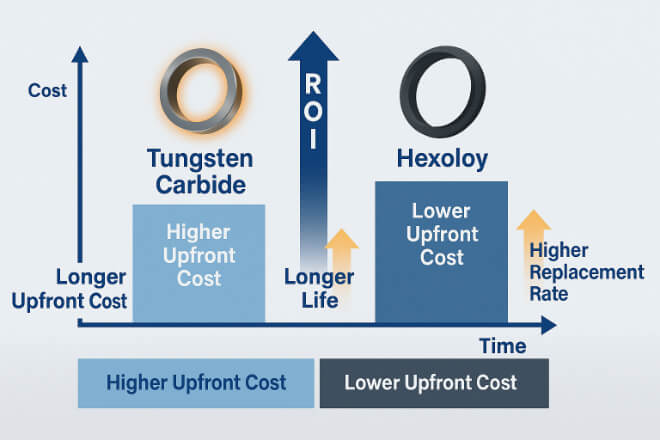

Cost and Life Cycle Considerations

When comparing Hexoloy vs tungsten carbide, decision-makers should look at life cycle cost, not just the purchase price.

Hexoloy may be cheaper upfront and ideal for chemical resistance, but higher replacement frequency in heavy-load conditions increases long-term costs.

Tungsten carbide costs more initially but offers longer service life in high-pressure, high-shock systems, lowering downtime costs.

Industry Applications: When to Choose Each

1). Hexoloy Seal Rings are best for:

Chemical plants with aggressive fluids

Marine seawater pumps where corrosion is the main risk

Lightweight systems where density matters

2). Tungsten Carbide Seal Rings are best for:

Power generation turbines and compressors

Oil and gas pumps exposed to high loads

Marine propulsion systems with heavy stress

Applications where downtime costs are high

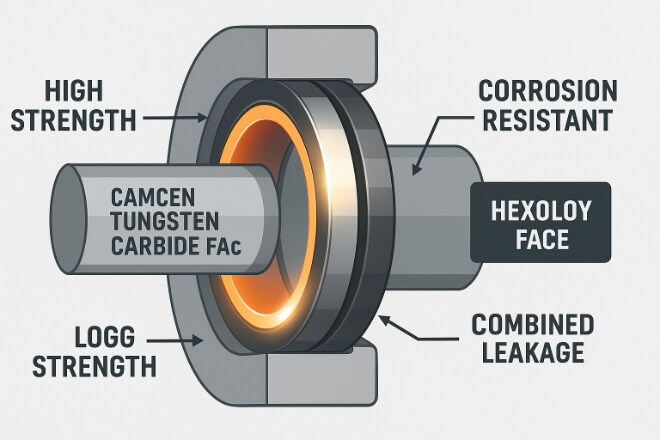

Hybrid Solutions

Some companies use a pair of different materials: one face made of tungsten carbide and the other of Hexoloy.

This allows systems to benefit from both toughness and corrosion resistance. Hybrid sealing faces often provide the best balance between performance and cost.

Key Takeaways for Decision-Makers

Choose Hexoloy when corrosion resistance, chemical compatibility, and lightweight design are priorities.

Choose tungsten carbide when toughness, heavy-load capacity, and long service life are required.

Consider hybrid solutions to combine the best properties of both.

The right choice depends on your specific operating environment, maintenance strategy, and long-term cost goals.

Conclusion

Both Hexoloy and tungsten carbide seal rings play important roles in modern sealing solutions.

Hexoloy offers superior corrosion resistance and thermal stability, while tungsten carbide provides unmatched toughness and durability under shock and pressure.

For decision-makers, the best option depends on the system’s environment.

In many cases, a careful life cycle cost analysis will show tungsten carbide is better for heavy-duty use, while Hexoloy is best for chemical-rich environments. In some situations, combining the two is the most effective strategy.

If you want to know more details about any company, please feel free to contact us.