High-pressure systems are found in many industries, from oil and gas to chemical plants and power generation.

These systems require reliable sealing components to prevent leakage, avoid downtime, and maintain safety. One of the best solutions for this challenge is the tungsten carbide seal ring.

Known for its strength, wear resistance, and durability under extreme pressure, these rings are trusted by industries worldwide.

This article explains why tungsten carbide seal rings are the preferred choice for high-pressure sealing, what makes them strong, and how they add value to industrial operations.

What Are Tungsten Carbide Seal Rings?

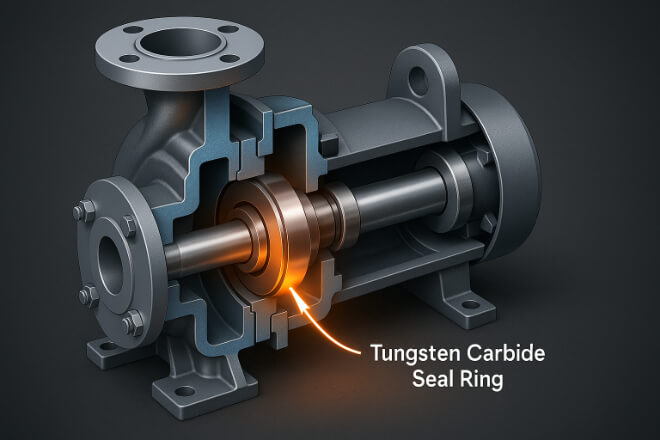

A tungsten carbide seal ring is a circular component made from tungsten carbide, a compound of tungsten and carbon.

It is often bonded with cobalt or nickel to improve toughness. The material is extremely hard, close to diamond in hardness, making it ideal for sealing applications.

These rings are used in pumps, compressors, and valves where high pressure, heat, and corrosive fluids make sealing difficult.

Their role is simple but critical: stop leakage and ensure system efficiency.

Key Properties That Support High-Pressure Sealing

The success of tungsten carbide seal rings in high-pressure systems comes from their unique material properties:

High Hardness – Prevents wear from friction and particle contact.

High Compressive Strength – Withstands extreme pressure without cracking or deforming.

Thermal Stability – Maintains strength even at high operating temperatures.

Corrosion Resistance – Performs well against water, chemicals, oil, and gas.

Dimensional Stability – Holds precise shape for tight sealing over time.

For industries dealing with high-pressure fluids, these properties mean fewer failures and longer service life.

Why High-Pressure Systems Need Reliable Seal Rings

High-pressure systems operate under extreme conditions. When a seal fails, results can be serious:

Costly downtime from system shutdowns

Risk of equipment damage

Safety hazards for workers

Environmental leaks leading to penalties

Tungsten carbide seal rings reduce these risks by ensuring reliable sealing performance.

For decision-makers, choosing high-quality sealing solutions directly affects productivity and safety.

Comparison with Other Seal Materials

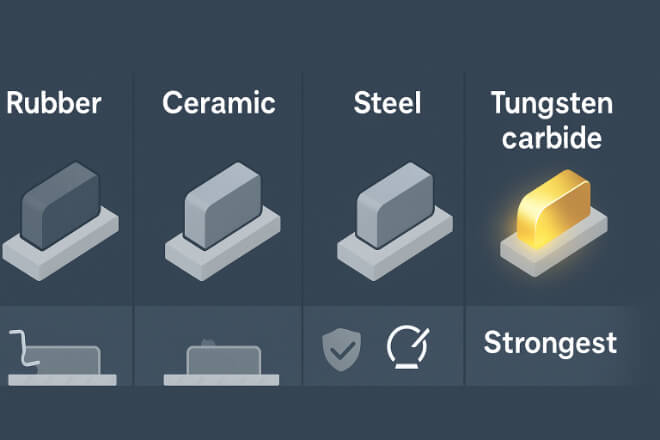

Not all seal materials are equal under high pressure.

Elastomers (rubber seals) – Flexible but not suitable for extreme heat or pressure.

Ceramic seals – Hard but brittle, prone to cracking under shock loads.

Steel seals – Strong but less resistant to wear and corrosion.

Tungsten carbide seal rings combine hardness, toughness, and chemical resistance, making them superior in high-pressure applications.

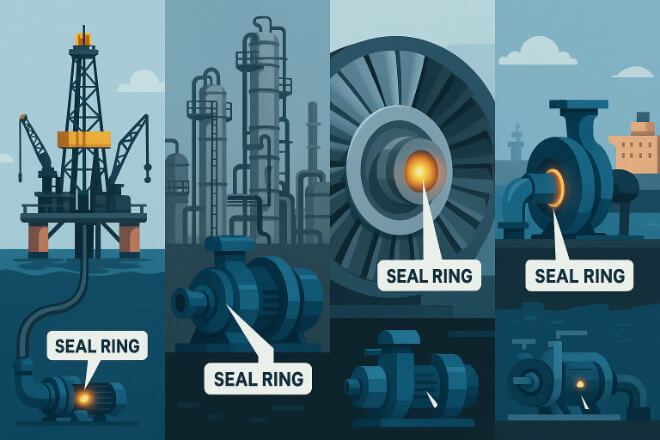

Industrial Applications of Tungsten Carbide Seal Rings

Many industries depend on tungsten carbide seal rings to handle demanding sealing needs:

Oil and Gas – Pumps and compressors operating under high pressure.

Chemical Plants – Seal rings resisting corrosive fluids and extreme heat.

Power Generation – Turbines, pumps, and cooling systems requiring reliable sealing.

Marine Industry – Sealing systems in ships and offshore equipment.

Wastewater Treatment – Pumps handling abrasive and corrosive fluids.

Across these sectors, reliability under pressure makes tungsten carbide seal rings the standard choice.

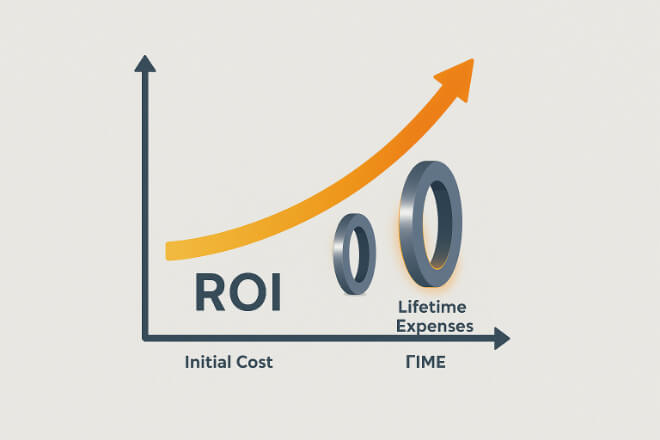

Cost vs Long-Term Value

While tungsten carbide seal rings cost more upfront than rubber or steel seals, they deliver better long-term value. Their durability means:

Less frequent replacement

Lower maintenance costs

Fewer shutdowns

Longer equipment life

For companies, the investment pays off through reduced downtime and higher system reliability.

Maintenance and Best Practices

To get the best performance from tungsten carbide seal rings, industries should follow simple practices:

Correct Installation – Ensure alignment and avoid surface damage.

Regular Inspection – Check for cracks, wear, or corrosion signs.

Proper Lubrication – Use suitable fluids to reduce friction and overheating.

Right Material Grade – Select nickel- or cobalt-bonded carbide depending on environment.

Following these steps ensures maximum life and reliable sealing under pressure.

Sustainability and Recycling

Tungsten carbide is not only durable but also recyclable. Worn seal rings can be collected, reprocessed, and reused.

This reduces environmental impact and supports circular economy goals, making it a sustainable sealing choice.

Conclusion

Tungsten carbide seal rings offer the strength, hardness, and stability needed for high-pressure sealing solutions.

Their proven performance in oil and gas, power generation, chemical, and marine industries shows why they are the trusted choice.

For decision-makers, investing in these rings means long-term savings, safety, and reliability.

If you want to know more details about any company, please feel free to contact us.