Industrial equipment in oil and gas, power generation, chemical plants, and marine systems often works under high-temperature and high-pressure conditions.

In such environments, sealing systems must not only stop leaks but also resist heat, wear, and chemical attack. A failure in seals can lead to dangerous leaks, downtime, and costly repairs.

One of the most reliable materials for these demanding conditions is tungsten carbide.

This article explains why high-temperature tungsten carbide seal rings are essential for industrial equipment, their advantages, and how they deliver long-term value for companies.

The Challenge of High-Temperature Sealing

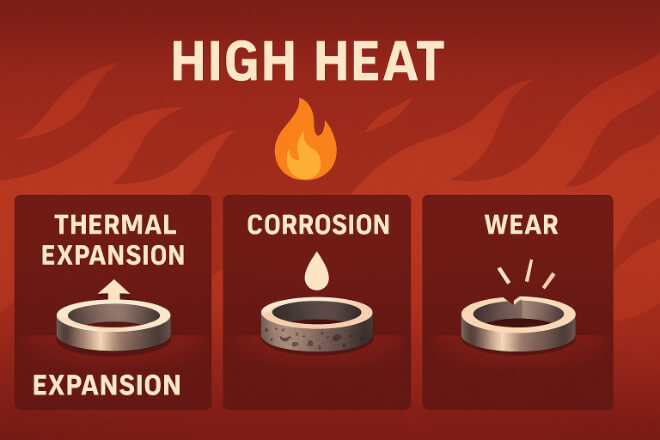

Seals exposed to high temperatures face unique problems:

Thermal expansion → Materials expand and contract, causing cracks or distortion.

Loss of strength → Softer materials weaken under heat.

Oxidation and corrosion → Heat accelerates chemical attack.

Wear and abrasion → High-temperature fluids often carry abrasive particles.

Industrial systems need a material that can resist these challenges while maintaining performance.

Properties of Tungsten Carbide Seal Rings

Tungsten carbide is a hard compound made from tungsten and carbon, bonded with cobalt or nickel.

Its properties make it ideal for high-temperature sealing:

Extreme hardness – Resists wear from friction and abrasive fluids.

High compressive strength – Withstands heavy loads and pressure.

Thermal stability – Maintains hardness and strength even at high temperatures.

Corrosion resistance – Protects against hot chemicals, oil, and seawater.

Dimensional stability – Ensures seals keep their precise shape over time.

These features allow tungsten carbide seal rings to work reliably in hot, high-pressure systems.

Performance in High-Temperature Environments

1). Oil and Gas

Drilling and refining equipment operates under extreme heat.

Tungsten carbide seal rings resist both hot hydrocarbons and abrasive drilling fluids, extending seal life.

2). Power Generation

Steam turbines and cooling pumps run at very high temperatures.

Tungsten carbide seal rings prevent leaks and maintain sealing strength under constant heat cycles.

3). Chemical Plants

Many chemical processes use hot, corrosive fluids. Nickel-bonded tungsten carbide rings provide strong resistance against these aggressive environments.

4). Marine Equipment

Marine pumps and propulsion systems exposed to hot seawater and friction stress benefit from tungsten carbide’s high thermal stability.

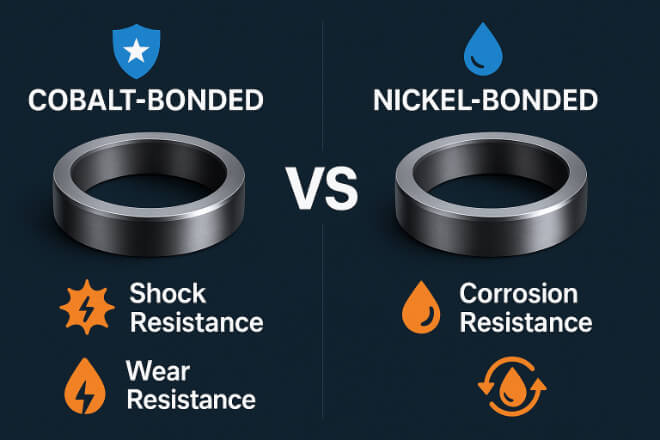

Cobalt-Bonded vs Nickel-Bonded Grades

1). Cobalt-bonded tungsten carbide

Offers greater toughness.

Best for equipment exposed to vibration and shock.

Performs well in oil and gas pumps.

2). Nickel-bonded tungsten carbide

Provides stronger corrosion resistance.

Best for chemical plants and marine applications.

Slightly less tough than cobalt-bonded.

Selecting the right grade ensures maximum life under high-temperature conditions.

Advantages Over Other Seal Materials

Steel seals → Lose strength under high heat, corrode easily.

Ceramic seals → Resist chemicals but brittle, crack under shock.

Silicon carbide → Good chemical resistance, but less tough under vibration.

Tungsten carbide → Best overall combination of toughness, durability, and thermal stability.

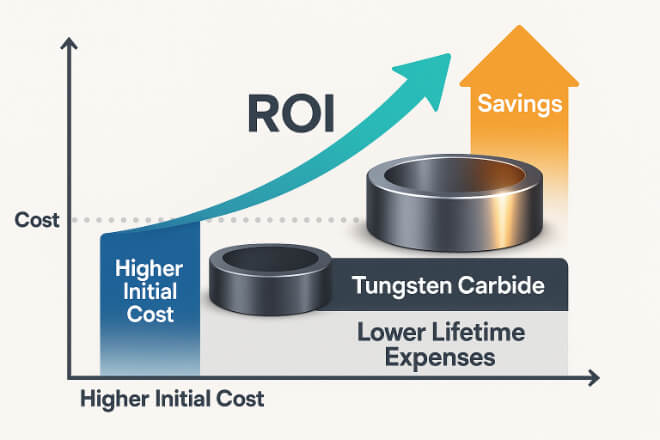

Cost vs Long-Term Value

Tungsten carbide seal rings are more expensive upfront than rubber, steel, or ceramic alternatives.

However, their long-term value is greater because they:

Last longer in high-heat systems.

Require fewer replacements.

Reduce downtime costs.

Protect equipment from damage.

For decision-makers, tungsten carbide rings lower the total cost of ownership.

Maintenance Best Practices for High-Temperature Use

To maximize the performance of tungsten carbide seal rings:

Choose the right binder → Nickel for corrosive, cobalt for shock.

Ensure correct installation → Avoid scratches that weaken seals.

Check operating conditions → Prevent overheating beyond design limits.

Inspect regularly → Look for early signs of cracks or wear.

Good maintenance practices extend seal life and reliability.

Sustainability and Recycling

Tungsten carbide is recyclable. Worn rings can be collected and processed into new products.

This reduces material waste and supports sustainability goals in industries focused on reducing environmental impact.

Key Takeaways for Decision-Makers

High-temperature tungsten carbide seal rings are essential for reliable sealing in oil, gas, power, chemical, and marine systems.

They provide superior wear resistance, thermal stability, and corrosion protection.

Choosing the right grade improves performance and life span.

Higher initial cost is offset by longer service life and reduced downtime.

Recycling adds further sustainability benefits.

Conclusion

For industries facing high heat and heavy stress, tungsten carbide seal rings are the best sealing choice.

Their ability to resist thermal stress, wear, and corrosion ensures safety, efficiency, and long-term cost savings.

For decision-makers, investing in tungsten carbide seal rings is both a technical solution and a strategic business decision.

If you want to know more details about any company, please feel free to contact us.