In today’s competitive industrial world, every decision-maker is under pressure to improve efficiency, reduce downtime, and cut operational cost.

Machines and equipment are the heart of production, and when they fail, the company loses not only money but also time and market opportunities. One of the smartest investments industries can make is in carbide wear parts.

Carbide wear parts are components made from tungsten carbide, a material well known for its hardness, durability, and wear resistance.

These qualities help machines last longer and perform better. This article will explain how carbide wear parts help reduce downtime and lower overall costs while supporting better business outcomes.

What Are Carbide Wear Parts?

Carbide wear parts are machine components designed to resist friction, heat, and wear during operation.

They are made using tungsten carbide combined with a metal binder (usually cobalt).

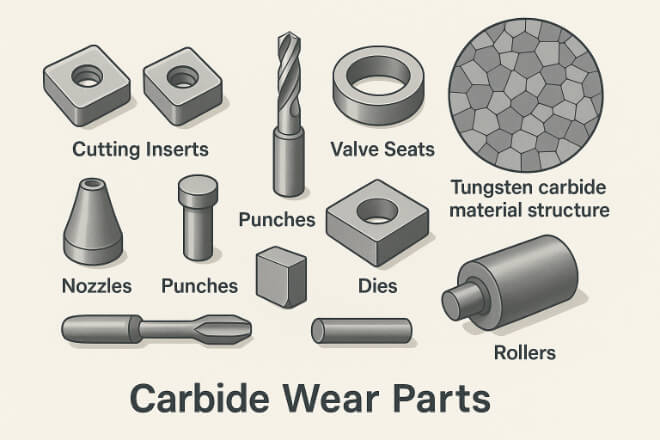

Examples include:

Drill bits

Valve seats

Punches and dies

Rollers

These parts are commonly used in mining, oil & gas, metal forming, paper, packaging, and woodworking industries.

Why Downtime Is Expensive

For industrial companies, downtime is one of the biggest hidden costs. A few hours of machine stoppage can mean:

Missed production targets

Extra labor cost for overtime

Contract penalties

Loss of customer trust

Some studies show that in heavy industries, one hour of downtime can cost thousands of dollars. That is why reducing downtime is a top priority for decision-makers.

How Carbide Wear Parts Reduce Downtime

Carbide wear parts directly help reduce downtime by lasting longer and performing better than steel or other materials. Here’s how:

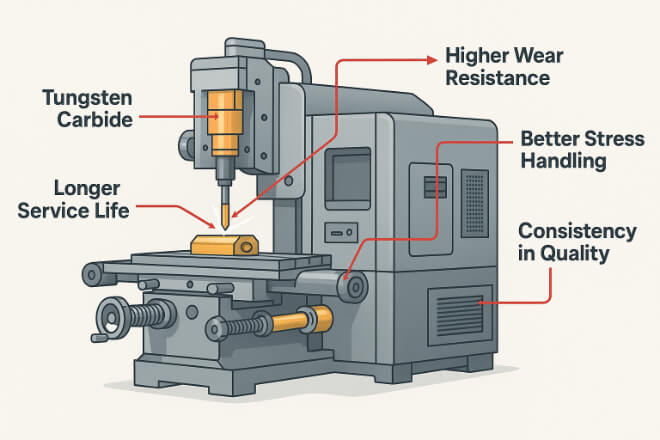

1). Higher Wear Resistance

Carbide is extremely hard, second only to diamond.

It resists abrasion and wear much better than traditional steel.

This means fewer breakdowns and fewer part replacements.

2). Better Performance Under Stress

Carbide parts handle high temperatures, pressure, and friction.

In mining drills or stamping tools, they stay sharp and reliable.

3). Longer Service Life

Machines run longer without interruption.

Maintenance intervals are reduced, leading to more uptime.

4). Consistency in Quality

Carbide ensures stable performance.

Fewer quality problems mean less rework and fewer delays.

Cost Benefits of Using Carbide Wear Parts

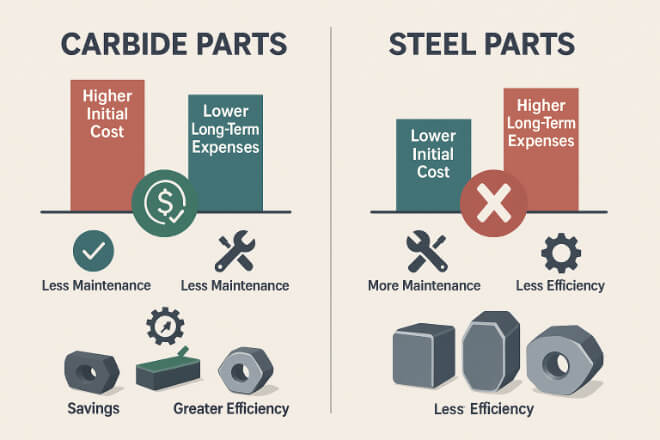

While carbide wear parts may cost more at the start, they save money in the long run.

Lower Replacement Costs

Steel parts wear out faster, so they need to be replaced often. Carbide parts last longer, meaning fewer purchases over time.

Less Labor and Maintenance Cost

Replacing parts takes labor, planning, and production stoppage. Longer-lasting carbide parts reduce these costs.

Energy Efficiency

Sharp and durable carbide tools cut and drill more efficiently, lowering machine energy use.

Higher Productivity

With fewer stoppages, companies meet production goals faster.

Case Example: Comparing Steel vs. Carbide

The difference between steel and carbide wear parts can be seen in their service life and cost impact.

| Factor | Steel Wear Parts | Carbide Wear Parts |

|---|---|---|

| Average Service Life | 1–3 months | 6–18 months |

| Replacement Frequency | High (frequent stoppages) | Low (fewer stoppages) |

| Downtime Cost | High (machine idle time) | Low (machines run longer) |

| Total Long-Term Cost | Higher due to replacements | Lower despite higher upfront cost |

This comparison shows that carbide is a long-term cost saver.

Industries That Benefit Most from Carbide Wear Parts

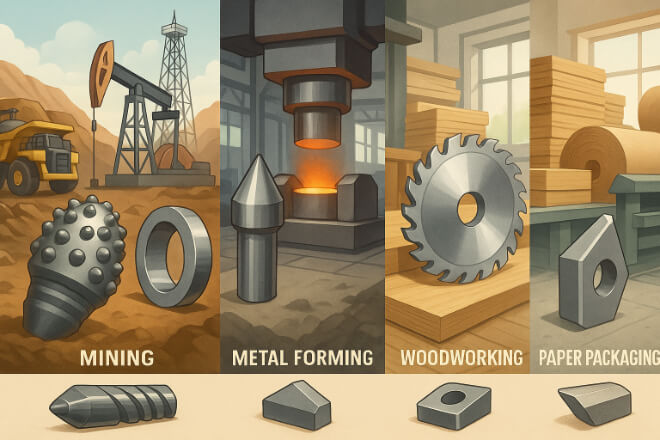

1). Mining and Drilling

Carbide drill bits and cutting tools last much longer in hard rock drilling.

Fewer tool changes mean less downtime underground.

2). Oil & Gas

Carbide nozzles, valve seats, and seals handle high pressure and abrasive fluids.

They keep pumps and valves working longer without leaks.

3). Metal Forming and Stamping

Carbide dies and punches resist deformation.

This improves accuracy and reduces frequent tool changes.

4). Woodworking and Paper Industry

Carbide blades and knives stay sharp longer.

Companies save both sharpening and replacement costs.

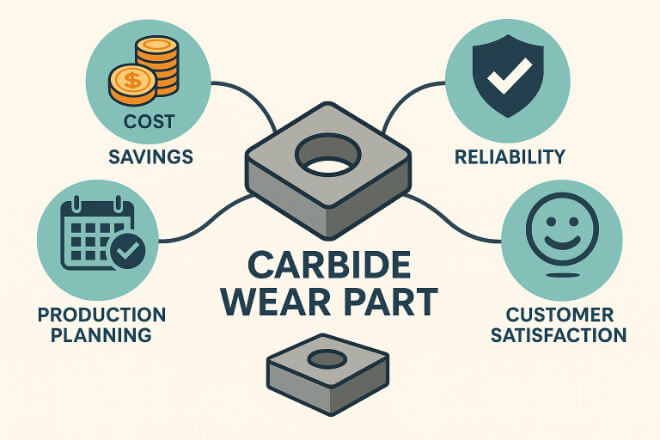

Strategic Benefits for Decision-Makers

For company leaders, carbide wear parts bring not only technical advantages but also business value:

Lower total cost of ownership (TCO)

Better equipment reliability

Improved production planning

Higher customer satisfaction

Investing in carbide is not only about performance—it’s a strategic move to improve competitiveness.

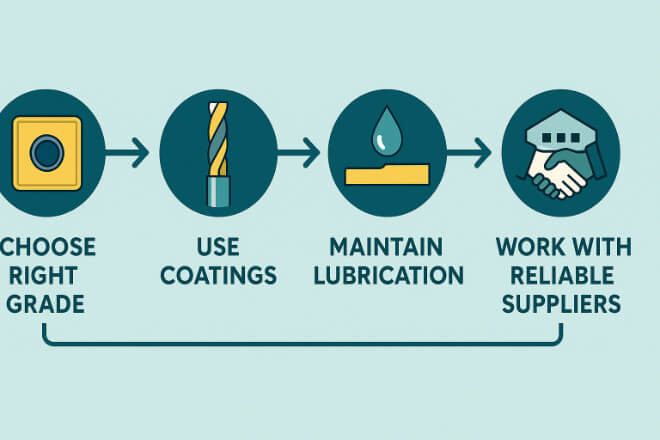

Tips to Maximize Value from Carbide Wear Parts

1). Choose the Right Grade

Different carbide grades suit different applications.

A trusted supplier can guide you in choosing the best one.

2). Use Proper Coatings

Coatings like TiN or TiAlN add extra wear resistance.

3). Maintain Proper Lubrication

Coolant and lubrication protect tools and extend their life.

4). Work with Reliable Suppliers

Partnering with experts ensures high-quality and consistent carbide parts.

Conclusion

Carbide wear parts are one of the best ways to reduce downtime and lower operational cost in demanding industries.

While they require a higher initial investment, their longer service life, reduced maintenance needs, and higher reliability make them a clear winner over traditional materials.

For decision-makers, adopting carbide wear parts means not only saving money but also ensuring stable production, higher efficiency, and stronger market competitiveness.

If you want to know more details about any company, please feel free to contact us.