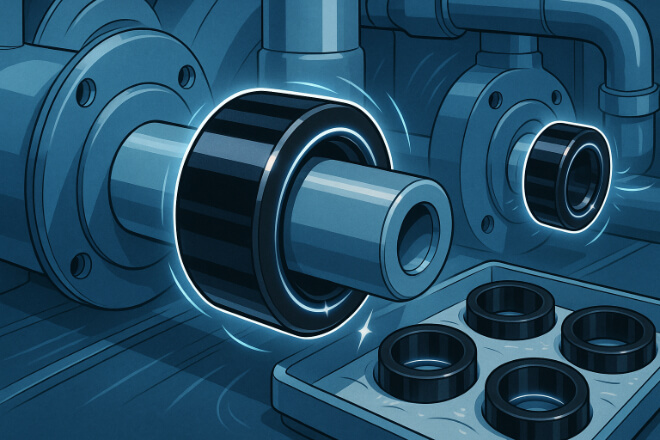

Tungsten carbide bushings are widely used in industries such as oil and gas, chemical processing, and machinery because of their excellent wear resistance and hardness.

However, even the best tungsten carbide surfaces can experience friction, corrosion, or premature wear under extreme conditions.

This is where advanced coatings such as TiN (Titanium Nitride) and DLC (Diamond-Like Carbon) come in.

These coatings enhance the surface properties of tungsten carbide bushings, providing additional protection and extending their operational life.

In this article, we will explore how these coatings work, their benefits, and how to choose the right one for your application.

Why Coatings Are Applied to Tungsten Carbide Bushings

Tungsten carbide is already a hard and durable material, but its performance can still be improved for specific operating environments.

Coatings act as a protective barrier, reducing direct contact between the bushing and its mating surface.

Main Purposes of Coatings:

Reduce friction between moving parts

Enhance wear resistance under high load or speed

Improve corrosion resistance in aggressive fluids

Prevent galling and sticking during operation

Extend overall service life of the bushing

By applying thin, high-performance coatings such as TiN or DLC, companies can achieve a better balance between performance, cost, and durability.

Overview of TiN and DLC Coatings

TiN and DLC are the most commonly used surface coatings for tungsten carbide components. Each has unique characteristics suited for different applications.

| Property | TiN (Titanium Nitride) | DLC (Diamond-Like Carbon) |

|---|---|---|

| Color & Appearance | Golden metallic finish | Deep black or dark gray finish |

| Hardness (HV) | 1,800 – 2,400 HV | 2,500 – 3,500 HV |

| Friction Coefficient | 0.4 – 0.6 | 0.05 – 0.2 |

| Corrosion Resistance | Good | Excellent |

| Typical Applications | Pump bushings, valves, cutting tools | High-speed bearings, dry-running systems |

How TiN Coating Improves Tungsten Carbide Bushings

TiN (Titanium Nitride) is a ceramic coating applied through Physical Vapor Deposition (PVD).

It forms a hard, thin layer—usually 2–5 microns thick—that improves wear and corrosion resistance while giving the surface a distinctive golden color.

1). Advantages of TiN Coating:

Higher Wear Resistance: The hard TiN layer reduces abrasion and surface fatigue.

Improved Heat Resistance: TiN performs well at high temperatures, making it suitable for high-speed machinery.

Reduced Friction: The coating creates a smoother surface, improving efficiency.

Chemical Stability: Resistant to oxidation and mild corrosion.

2). Best Applications:

Oil & gas pump bushings

Industrial seals

Cutting or drilling systems operating under heat and pressure

TiN-coated bushings are ideal for environments that combine mechanical wear with moderate corrosion.

How DLC Coating Improves Tungsten Carbide Bushings

DLC (Diamond-Like Carbon) coatings are among the hardest and most advanced surface coatings available.

They combine diamond-like hardness with graphite-like smoothness, producing extremely low friction.

1). Advantages of DLC Coating:

Ultra-Low Friction: DLC dramatically reduces friction, especially under dry or boundary lubrication.

Excellent Wear Resistance: The coating resists abrasive and adhesive wear even under high loads.

Superior Corrosion Protection: Ideal for aggressive fluids, chemicals, or saltwater.

Enhanced Service Life: Extends operational life and reduces maintenance costs.

2). Best Applications:

Subsea and chemical process pumps

Dry-running systems and compressors

Aerospace and automotive components

DLC coatings are more expensive but deliver exceptional performance, especially where lubrication is limited or environmental protection is critical.

Comparing TiN and DLC Coatings

The following comparison helps determine which coating is best for specific conditions:

| Criterion | TiN Coating | DLC Coating |

|---|---|---|

| Wear Resistance | High | Very High |

| Friction Coefficient | 0.4 – 0.6 | 0.05 – 0.2 |

| Temperature Resistance | Excellent (up to 600°C) | Good (up to 350°C) |

| Corrosion Resistance | Moderate to Good | Excellent |

| Cost | Lower | Higher |

In summary:

Choose TiN when high temperature and abrasion resistance are key.

Choose DLC for low friction and chemical protection.

Maintenance Tips for Coated Tungsten Carbide Bushings

Proper maintenance ensures coated bushings continue performing as intended.

Maintenance Guidelines:

Avoid abrasive cleaning tools that can scratch the coating.

Inspect regularly for wear, chipping, or discoloration.

Use compatible lubricants to avoid chemical reaction with the coating.

Avoid shock loads that can cause micro-cracks in the coating.

Store properly in a dry, dust-free environment before installation.

Conclusion

Both TiN and DLC coatings provide excellent ways to enhance the performance of tungsten carbide bushings.

TiN is ideal for high-temperature, mechanical applications, while DLC excels in low-friction, corrosion-prone environments.

By selecting the right coating and following proper maintenance practices, companies can significantly extend equipment life, improve performance, and reduce operating costs.

If you want to know more details about any company, please feel free to contact us.