Tungsten carbide bushings are widely used in industrial applications due to their outstanding wear resistance, hardness, and durability.

However, to maximize their performance, the density of the tungsten carbide must be optimized during the manufacturing process.

Hot Isostatic Pressing (HIP) is one of the most effective methods used to enhance the density of tungsten carbide bushings, ensuring their superior mechanical properties.

This article will explore how HIP works, its benefits, and why it is essential for improving the quality and performance of tungsten carbide bushings.

What is Hot Isostatic Pressing (HIP)?

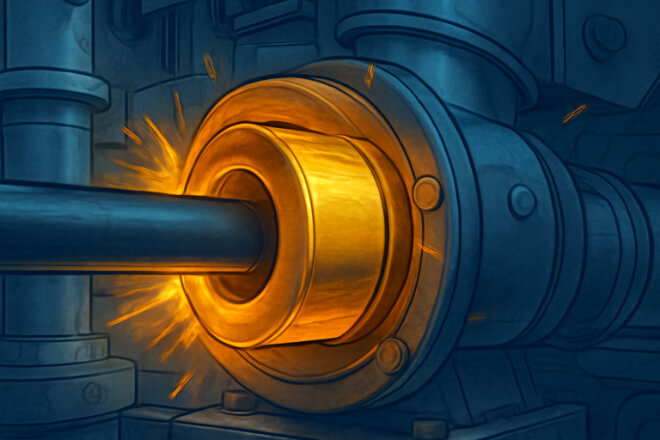

Hot Isostatic Pressing (HIP) is a manufacturing process used to improve the density and mechanical properties of materials, particularly metals and ceramics like tungsten carbide.

In this process, materials are subjected to both high temperature and high-pressure conditions in an isostatic (uniform) manner, meaning the pressure is applied equally from all directions.

How Does HIP Work?

High Temperature: The material is heated to a specific temperature, typically above the material’s sintering point, to ensure that the particles can bond more effectively.

High Pressure: Simultaneously, high pressure is applied uniformly from all directions, causing the pores in the material to close and increasing the material’s density.

Isostatic Pressure: Unlike traditional pressing, which applies pressure in one direction, HIP ensures that the pressure is applied equally in all directions, leading to a more uniform material.

This combination of heat and pressure ensures that tungsten carbide bushings become denser, stronger, and more durable.

How Does HIP Improve Tungsten Carbide Bushing Density?

Density is a key factor in determining the performance of tungsten carbide bushings.

A higher density means fewer pores or voids within the material, leading to better wear resistance, strength, and durability. HIP plays a critical role in achieving these desired properties.

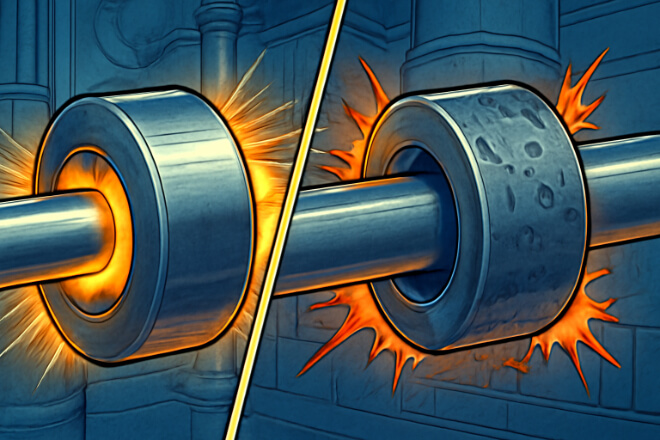

1). Eliminating Porosity

One of the main reasons for low density in tungsten carbide parts is porosity, which can form during the sintering process.

Porosity occurs when gas or air is trapped within the material, creating tiny voids or holes. These voids weaken the material and can reduce its ability to withstand pressure, wear, and impact.

How HIP Helps:

HIP effectively eliminates porosity by applying uniform pressure, causing the pores to collapse and the material to densify. This results in stronger and more resistant tungsten carbide bushings.

2). Uniform Density Distribution

In traditional sintering processes, the material can sometimes have non-uniform density, with some areas being denser than others.

This can lead to inconsistencies in performance, as weaker areas may wear faster or fail under stress.

How HIP Helps:

HIP applies pressure uniformly in all directions, ensuring a consistent density across the entire bushing. This results in more reliable and durable components.

3). Enhanced Mechanical Properties

Higher density directly correlates with improved mechanical properties, such as:

Increased wear resistance

Improved toughness

Enhanced impact resistance

These properties make HIP-treated tungsten carbide bushings ideal for high-stress applications in industries like mining, oil & gas, and machinery, where durability is paramount.

Benefits of HIP for Tungsten Carbide Bushings

The use of Hot Isostatic Pressing in the production of tungsten carbide bushings offers several key advantages, especially in industries that require high performance and durability.

1). Superior Wear Resistance

Denser tungsten carbide bushings exhibit superior wear resistance, meaning they can withstand harsh conditions for longer periods of time.

This is crucial for industries that rely on high-speed or high-load machinery, where bushings are subjected to constant friction.

1.1). Applications:

Mining equipment

Automotive components

Pumps and valves

2). Improved Strength and Toughness

With reduced porosity and a more uniform structure, HIP-treated tungsten carbide bushings are stronger and more resilient.

They can absorb more shock and impact without cracking, which is especially important in heavy-duty machinery and tools that experience fluctuating loads.

2.1). Applications:

Drilling equipment

Heavy machinery

Aerospace components

3). Longer Service Life

Because of their enhanced density and durability, HIP-treated tungsten carbide bushings have a longer service life than traditionally sintered bushings.

This leads to fewer replacements, reduced downtime, and ultimately, lower overall operational costs.

3.1). Applications:

Power generation equipment

Hydraulic systems

Marine and offshore equipment

4). Increased Precision

The improved consistency in density and material properties means that HIP-treated bushings can be manufactured with greater precision, ensuring better fitting and performance in machinery.

This is especially beneficial for high-precision applications in industries like aerospace and semiconductor manufacturing.

Applications of HIP in Tungsten Carbide Bushing Production

Hot Isostatic Pressing is particularly beneficial in industries where high-performance materials are required.

The process is commonly used in the production of tungsten carbide bushings for the following applications:

1). Mining Industry

In mining, equipment is subjected to harsh wear conditions, including abrasion and impact.

HIP-treated tungsten carbide bushings provide superior wear resistance, making them ideal for use in drilling equipment, crushers, and conveyors.

2). Oil & Gas Industry

The oil and gas industry often requires materials that can withstand high temperatures and harsh chemicals.

HIP-treated tungsten carbide bushings are used in downhole drilling equipment, pumps, and valves, where corrosion and wear resistance are critical.

3). Aerospace Industry

In aerospace, precision and durability are essential. HIP-treated tungsten carbide bushings are used in high-performance components like engines, turbines, and landing gear, where strength, wear resistance, and high-density material are key.

Conclusion

Hot Isostatic Pressing is a powerful technique for improving the density and performance of tungsten carbide bushings.

By eliminating porosity and ensuring uniform density distribution, HIP-treated bushings offer superior wear resistance, greater strength, and longer service life.

These qualities make HIP an essential process for industries requiring high-performance materials, including mining, oil & gas, and aerospace.

For decision-makers looking to improve the durability and efficiency of their equipment, understanding the role of HIP in tungsten carbide bushing production is key to choosing the right materials for extreme conditions.

If you want to know more details about any company, please feel free to contact us.