Tungsten carbide bushings are known for their exceptional durability, hardness, and wear resistance, making them ideal for high-performance applications.

However, during installation, press-fitting tungsten carbide bushings into housings or shafts can sometimes lead to cracks or fractures, especially if the fit is too tight or improper installation techniques are used.

This article will explore how to press-fit tungsten carbide bushings effectively, how to prevent cracking, and the best practices for ensuring that the bushing maintains its integrity throughout the installation process.

What Is Press-Fitting?

Press-fitting is the process of installing a bushing into a housing or onto a shaft by applying force to create an interference fit.

The goal is to create a secure and stable connection between the bushing and the surrounding components.

However, when dealing with tungsten carbide, which is a brittle material, excessive pressure or improper methods can lead to cracks or even catastrophic failure of the bushing.

Why Press-Fitting Is Crucial:

Secure fit: A proper press-fit ensures the bushing stays in place during operation, preventing movement, misalignment, or loosening.

Prevent failure: Ensuring the correct installation technique reduces the risk of cracks, chips, and fractures that could result in early failure.

Functionality: For optimal performance, the bushing must be securely fitted while maintaining its structural integrity.

The Risks of Improper Press-Fitting

When press-fitting tungsten carbide bushings, improper installation techniques can result in stress concentration at the edges of the bushing.

This can lead to the formation of cracks or chips that compromise the bushing’s performance.

Key Risks:

Cracks and Fractures: If too much force is applied, it can cause the brittle tungsten carbide to crack, leading to failure during operation.

Surface Damage: Incorrect press-fitting can cause surface stress, leading to scratches, chips, or microfractures that reduce the wear resistance of the bushing.

Misalignment: Uneven press-fit force can lead to misalignment of the bushing, which can cause additional wear and stress on the surrounding components.

Factors Affecting the Press-Fit Process

Several factors must be taken into account when press-fitting tungsten carbide bushings to avoid cracking or other damage.

Key Factors:

Bushing Material: Tungsten carbide is very hard but also brittle, which makes it sensitive to the stresses involved in press-fitting. The choice of binder material (such as cobalt or nickel) can also affect the material’s toughness.

Interference Fit: The amount of interference between the bushing and the housing or shaft is crucial. Too much interference can lead to excessive stress, while too little can cause the bushing to loosen over time.

Temperature: Pre-heating the housing or shaft before press-fitting can help minimize thermal stresses that could cause cracking.

Press-Fit Tools: Using the right tools for the job is essential. Using improper tools can lead to uneven application of force, increasing the risk of damaging the bushing.

Best Practices for Press-Fitting Tungsten Carbide Bushings

To ensure the proper installation of tungsten carbide bushings, the following best practices should be followed:

Best Practices:

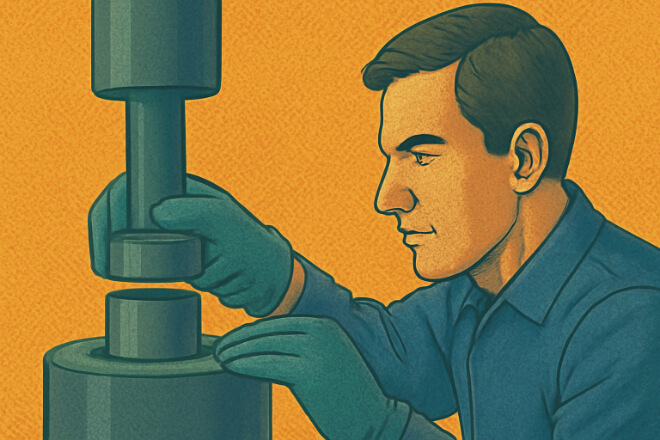

Use Controlled Force: Apply the press-fit force gradually and evenly to prevent the creation of stress points. Avoid using too much force, as this can cause cracks. Hydraulic presses or press-fit machines are often ideal for providing controlled, even pressure.

Pre-Heat the Housing or Shaft: Pre-heating the housing or shaft can reduce the temperature difference between the bushing and the surrounding components, which can help reduce thermal shock and prevent cracking.

Check the Fit: Before applying full force, check that the fit is appropriate. The bushing should fit snugly without the need for excessive force.

Use a Mandrel or Press Tool: A mandrel or appropriate press tool ensures that the bushing is aligned properly during installation, preventing misalignment and ensuring an even press-fit.

Lubricate the Bushing: Using a lubricant can help reduce friction during installation, making the press-fit process smoother and reducing the risk of cracking.

Preventing Cracking During Installation

Preventing cracks during installation is a primary concern when press-fitting tungsten carbide bushings. The following methods can help reduce the risk of cracks:

Preventative Measures:

Gradual Pressing: Avoid sudden or jerky movements when applying force. Gradually pressing the bushing into place will reduce the likelihood of cracks forming.

Proper Alignment: Ensure that the bushing is aligned properly with the housing or shaft before applying pressure. Misalignment can cause uneven stress, leading to cracks.

Even Pressure Distribution: Use a press tool with a large contact surface to evenly distribute the force across the bushing’s surface. This prevents localized stress concentrations that can cause cracking.

Material Considerations: Consider using tungsten carbide bushings with a nickel binder (WC-Ni) rather than a cobalt binder (WC-Co). WC-Ni bushings are generally more ductile, making them less prone to cracking during press-fitting.

Measuring the Success of Press-Fit Installation

After the press-fit process, it’s important to check that the bushing has been installed properly without causing any damage. Here are a few ways to measure the success of the installation:

Measurement Techniques:

Dimensional Check: Measure the bushing’s fit after installation to ensure that it has been installed correctly. The fit should be snug without excessive interference.

Visual Inspection: Inspect the bushing for any visible cracks or damage. A bushing that has been press-fitted correctly should have no surface imperfections.

Friction and Wear Testing: Conduct friction and wear tests to ensure that the bushing is functioning as intended, without excessive friction or wear from misalignment or damage.

Conclusion

Press-fitting tungsten carbide bushings requires careful attention to detail and proper techniques to avoid cracking or damage.

By following best practices, such as applying controlled force, pre-heating the housing or shaft, and using appropriate press-fit tools, you can ensure that the bushing is installed securely and without compromising its integrity.

Taking the necessary precautions during the press-fit process will help you achieve a durable, long-lasting installation, improving the performance and lifespan of your machinery.

If you want to know more details about any company, please feel free to contact us.