Tungsten carbide tips are widely used for their exceptional hardness, durability, and wear resistance.

However, like all cutting tools, they lose their sharpness over time, affecting performance and productivity.

Proper sharpening of tungsten carbide tips is crucial to restoring their cutting efficiency and prolonging their lifespan.

In this article, we will discuss the importance of sharpening, how to properly sharpen tungsten carbide tips, and the best practices to ensure optimal performance.

Why Sharpening Tungsten Carbide Tips is Important

Sharpening tungsten carbide tips is necessary to maintain their cutting performance and ensure they operate efficiently. Over time, even the hardest tips wear down, causing them to lose their edge.

Dull carbide tips can lead to increased friction, heat, and wear on both the tool and the material being cut.

Properly sharpened tips not only improve the tool’s performance but also reduce the strain on the machinery, increase accuracy, and minimize operational downtime.

Regular sharpening also helps extend the life of the tungsten carbide tips by preventing damage from excessive wear.

By addressing the sharpness issue early, you can avoid costly replacements and improve overall productivity.

Tools and Equipment Needed for Sharpening

To properly sharpen tungsten carbide tips, you need the right equipment. Below are the essential tools required for the process:

Diamond Grinding Wheels:

Tungsten carbide is a hard material, so diamond grinding wheels are necessary to achieve the desired sharpness.

These wheels come in various grit sizes, so selecting the right one for your application is key.

Sharpening Machine:

A precision sharpening machine is recommended to ensure uniform sharpening and maintain the correct angle of the tip.

Cooling System:

Tungsten carbide can overheat during the sharpening process, which can cause thermal damage.

A cooling system or coolant is necessary to prevent overheating and maintain the integrity of the tips.

Measuring Tools:

Calipers and micrometers are important for checking the sharpness and the overall dimensions of the tip to ensure the desired results are achieved.

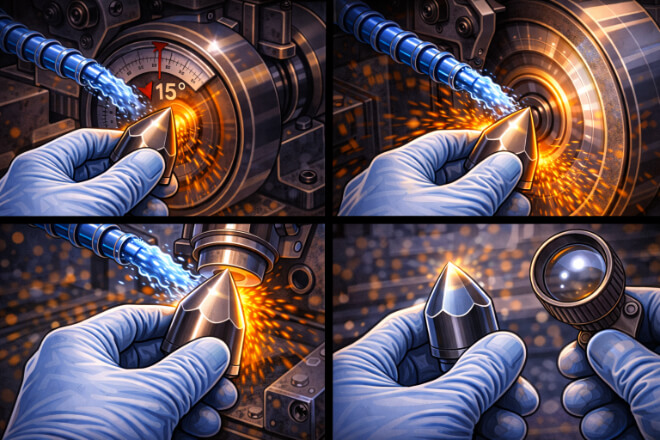

Understanding the Correct Sharpening Angle

One of the most important factors in sharpening tungsten carbide tips is maintaining the correct sharpening angle.

The sharpening angle depends on the specific application of the carbide tip, but in general, the optimal angle ranges from 10° to 20°.

A steeper angle may offer a sharper edge, but it could be more prone to chipping, while a shallower angle may reduce cutting efficiency.

To achieve the correct angle, use a precision sharpening machine equipped with an adjustable table. Always follow the manufacturer’s recommendations for the specific tool you are sharpening.

Step-by-Step Process for Sharpening Tungsten Carbide Tips

Follow these steps to properly sharpen tungsten carbide tips:

Set Up the Equipment: Secure the diamond grinding wheel to the sharpening machine. Attach the cooling system to ensure the carbide tips do not overheat during the process.

Position the Tip: Place the tungsten carbide tip securely in the machine, ensuring it is stable and properly aligned. The tip should be positioned so that it is perpendicular to the grinding wheel.

Start Grinding: Slowly lower the tip onto the grinding wheel, allowing the wheel to make contact with the tip’s cutting edge. Use light pressure to avoid overheating or damaging the carbide.

Maintain the Angle: As the grinding progresses, ensure the sharpening angle remains consistent. Adjust the sharpening machine’s settings to maintain the correct angle as needed.

Cool the Tip: Throughout the process, continuously apply coolant to the tip to prevent overheating. This will also help flush away any debris from the grinding process.

Check for Sharpness: After grinding, inspect the tip’s edge for sharpness using a magnifying tool. If necessary, repeat the grinding process to achieve the desired sharpness.

Finish and Clean: Once the tip is sharpened, remove it from the machine and clean it thoroughly to remove any remaining coolant and debris.

Common Mistakes to Avoid When Sharpening Tungsten Carbide Tips

While sharpening tungsten carbide tips, it’s easy to make mistakes that can reduce tool life or cause damage. Here are some common mistakes to avoid:

Using the Wrong Grinding Wheel: Ensure that you are using a diamond grinding wheel specifically designed for carbide. Using a non-diamond wheel will not produce the desired results and can damage the tool.

Overheating the Tip: Overheating tungsten carbide can cause it to lose its hardness and become brittle. Always use a cooling system to prevent overheating during the sharpening process.

Incorrect Angle: Sharpening the tip at an incorrect angle can affect cutting performance and cause premature wear. Always check and maintain the correct angle for your application.

Excessive Pressure: Applying too much pressure during sharpening can cause the tip to break or crack. Use light pressure to allow the grinding wheel to do the work.

When to Sharpen Tungsten Carbide Tips

Knowing when to sharpen tungsten carbide tips is just as important as knowing how to sharpen them. Here are a few signs that it’s time to sharpen your carbide tips:

Reduced Cutting Efficiency: If the tips are not cutting as smoothly as they once did, it may be time to sharpen them. Dull tips require more force to cut, reducing overall efficiency.

Visible Wear: If you notice visible wear or rounding of the cutting edge, sharpening is necessary to restore the tip’s sharpness.

Increased Heat Generation: If the tips are generating excessive heat during use, it could be a sign of dullness. Sharpening the tips will help reduce friction and heat generation.

Conclusion

Properly sharpening tungsten carbide tips is essential for maintaining optimal performance and extending the life of your tools.

By following the right techniques, using the correct equipment, and avoiding common mistakes, you can ensure that your carbide tips remain sharp and effective.

Regular sharpening not only improves cutting efficiency but also saves costs on replacements and reduces downtime in your operations.

Remember to follow the correct procedures, and always monitor your tools to ensure they are performing at their best.

If you want to know more details about any company, please feel free to contact us.