Tungsten carbide cutting tools are known for their incredible durability and long-lasting edge retention.

However, even the strongest tools wear down with regular use. Instead of replacing dull tools every time, you can often sharpen or recondition them to restore their performance and extend their life.

This not only saves money, but also helps maintain consistent machining quality and reduces production downtime.

In this article, we’ll walk through everything you need to know about sharpening and reconditioning tungsten carbide cutting tools.

From when to sharpen, what equipment you need, to how reconditioning differs from simple sharpening, this guide is ideal for both beginners and experienced machinists looking to improve their tooling strategy.

1. Why Carbide Tools Become Dull

Even though tungsten carbide is extremely hard—much harder than steel—it still wears down over time.

Continuous cutting, friction, high temperatures, and impact from materials all contribute to tool wear.

As a carbide cutting tool dulls, it begins to lose efficiency, producing poor-quality cuts and placing extra strain on both the tool and the machine.

A dull edge increases the cutting force required, leading to more heat and faster breakdown. This can ultimately result in tool breakage or damage to the workpiece.

Understanding how and when tools wear out is key to knowing when sharpening is necessary. By catching tool wear early, you can maintain precision, reduce scrap parts, and improve your shop’s efficiency overall.

2. Signs It’s Time to Sharpen or Recondition

Tungsten carbide tools don’t suddenly stop working—they slowly degrade over time.

To avoid reduced efficiency or tool failure, you should recognize early signs of dullness. Here are a few things to watch for:

The tool requires more force or slower feeds to achieve the same result.

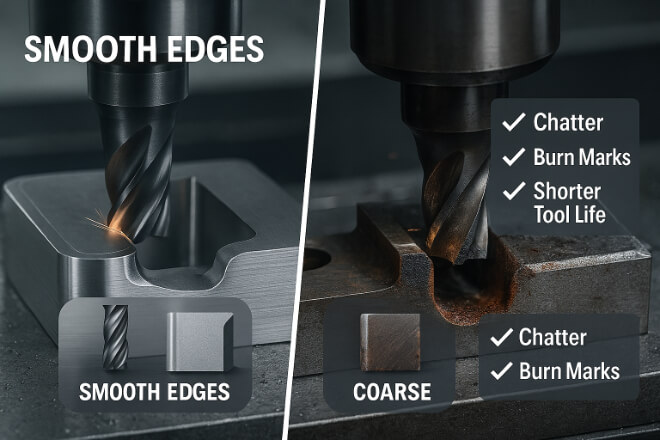

You notice burn marks, chatter, or poor surface finish on the material.

Chips become discolored or powdery rather than uniform.

Cutting noise increases, or vibration occurs more frequently.

Tool life becomes shorter between changes.

If any of these symptoms appear, it’s time to stop and consider sharpening or reconditioning the tool before further damage occurs.

3. Tools and Equipment Needed for Sharpening

Sharpening tungsten carbide is different from sharpening regular steel. Because carbide is so hard, it requires diamond abrasives and specialized grinding machines. Here’s what’s typically used:

Diamond grinding wheels: These are the only effective option for sharpening carbide due to its hardness.

Tool and cutter grinder: A precision machine that holds the tool at consistent angles during sharpening.

Coolant system: Helps reduce heat buildup, which could damage the tool or reduce hardness.

Magnifier or microscope: Used for close inspection of tool edges before and after sharpening.

Personal protection equipment (PPE): Includes goggles, gloves, and dust masks to protect from fine particles and sharp edges.

It’s possible to sharpen simple tools in-house if you have the proper setup, but more complex tools are often best handled by professional services.

4. How to Sharpen Tungsten Carbide Tools (Step-by-Step)

Sharpening tungsten carbide requires patience and precision. Here is a step-by-step guide:

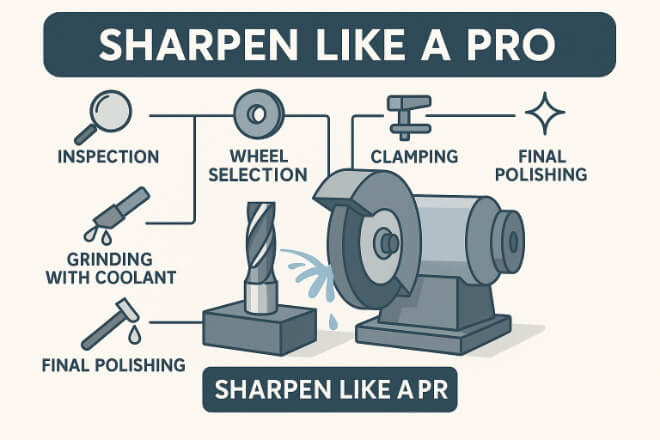

Step 1: Inspect the Tool

Look for signs of damage. If there are deep chips or cracks, reconditioning or replacement may be better.

Step 2: Choose the Right Diamond Wheel

Select a wheel that matches the tool geometry and desired finish. Use resin-bonded for smooth edges and vitrified for heavier grinding.

Step 3: Set the Tool in the Grinder

Clamp the tool correctly to maintain rake and relief angles. Inconsistent setups lead to uneven sharpening and poor cutting.

Step 4: Apply Coolant and Start Grinding

Turn on the grinder and apply light, consistent pressure. Use coolant to avoid overheating.

Step 5: Inspect and Polish

After grinding, use a magnifier to check the edge quality. Hone or polish if necessary to remove burrs and enhance cutting action.

Sharpening restores the edge, but doesn’t change the tool’s profile. For full restoration, reconditioning is the next level.

5. What is Tool Reconditioning?

Tool reconditioning includes sharpening, but it also involves reshaping, recoating, and sometimes rebuilding worn tools.

It’s often used for more valuable tools or those with custom geometry.

What Reconditioning Typically Includes:

Cleaning and inspecting the tool for cracks or wear.

Grinding the tool back to its original geometry.

Polishing flutes and adjusting clearance angles.

Reapplying a suitable coating.

Final edge inspection and balancing (if needed).

Well-reconditioned tools can offer performance close to new tools at a much lower cost. It’s a great option when tool life, performance, and sustainability matter.

6. Choosing the Right Coating for Reconditioned Tools

A tool’s coating plays a major role in how well it resists wear, friction, and heat.

When you recondition a tool, reapplying the right coating can bring it close to new condition. Common coatings include:

TiAlN (Titanium Aluminum Nitride) – Ideal for high-heat applications and dry machining.

AlTiN – Offers excellent heat and oxidation resistance.

DLC (Diamond-Like Carbon) – Good for non-ferrous materials like aluminum or plastics.

CVD Diamond Coating – Ultra-hard coating for cutting abrasive materials such as composites and graphite.

7. Sharpening vs. Reconditioning: What’s the Difference?

Sharpening is best when only the edge is worn. It’s fast, simple, and cost-effective.

Reconditioning is better for tools with heavier wear, complex geometries, or coatings that need replacement.

Sharpening usually extends tool life by one or two cycles. Reconditioning can give tools a second or even third life.

For high-value carbide tools, reconditioning often delivers the best return on investment.

8. Cost Analysis: Save More with Reuse

Carbide tools are expensive, but reusing them through sharpening and reconditioning brings major savings.

You might spend more upfront on a regrind or recoat, but you avoid buying new tools every time. Over the long term, this reduces tool costs by 30–60% depending on the application.

And let’s not forget the cost of downtime, poor surface finish, or scrapped parts—all reduced when you use sharp, properly maintained tools.

Final Thoughts

Sharpening and reconditioning tungsten carbide cutting tools is one of the smartest strategies for modern machine shops.

With the right timing, equipment, and expertise, you can save money, reduce waste, and keep your production running at peak efficiency.

If you want to know more details about any company, please feel free to contact us.