In modern industries, small parts often make the biggest difference. One of these key parts is the tungsten carbide ball.

These balls are strong, hard, and durable, making them perfect for use in many machines and systems.

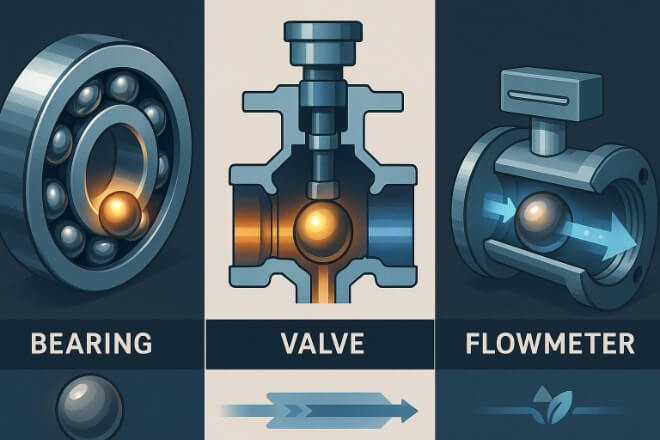

From valves to bearings, from oil tools to measuring devices, tungsten carbide balls help companies reduce downtime, save costs, and improve performance.

This guide explains how to use tungsten carbide balls in different applications. It is written in simple English for decision-makers in industries like oil & gas, automotive, chemical, aerospace, and manufacturing.

By the end, you will know where to apply them, how to select the right type, and how to maintain them for long life.

What Are Tungsten Carbide Balls?

Tungsten carbide balls are precision balls made from a compound of tungsten and carbon.

They are much harder than steel balls and keep their strength even under high pressure, high temperature, or corrosive conditions.

Key properties:

Very high hardness

Strong resistance to wear

Long service life

Stable performance under extreme conditions

These properties make them the right choice for industries where reliability and accuracy are important.

Common Uses of Tungsten Carbide Balls

Tungsten carbide balls are used in many industries. Below are the most common applications.

Bearings

In heavy-duty bearings, carbide balls carry loads and keep machines running smoothly. They reduce wear and last much longer than steel balls.

In pumps, pipelines, and drilling systems, carbide balls are used as check valve components.

They seal tightly even under high pressure and in corrosive liquids.

Flowmeters

Carbide balls inside flowmeters help control and measure liquid or gas flow. They ensure precision and do not wear out quickly.

Aerospace and Automotive

In engines, fuel systems, and control parts, tungsten carbide balls add strength and improve reliability.

Oil & Gas Drilling

In mud motors and drilling tools, carbide balls resist abrasion and maintain function in high-impact situations.

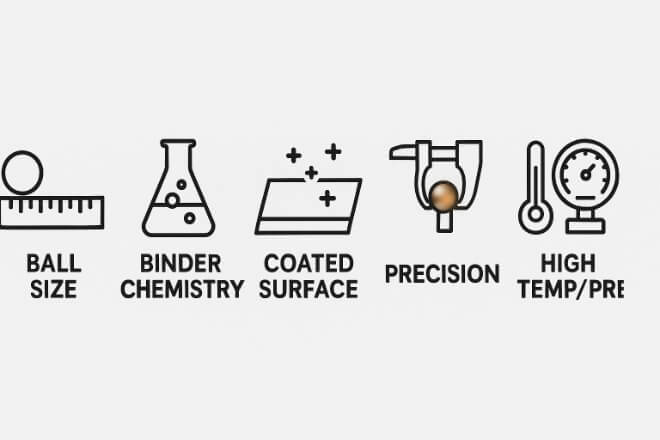

How to Choose the Right Tungsten Carbide Ball

Selecting the right ball is important for performance. Here are the main factors:

Size and Diameter – Choose the correct size for your system or bearing. Even a small size error can cause failure.

Grade of Carbide – Some balls have cobalt as binder, others nickel. The binder affects corrosion resistance and toughness.

Coating – Coated carbide balls resist friction and last longer in high-wear environments.

Precision Grade – For measuring tools and flowmeters, high-precision grades are required.

Working Environment – Consider temperature, pressure, and type of fluid or gas in the system.

Best Practices for Using Tungsten Carbide Balls

Using these balls correctly extends their life and saves costs. Follow these steps:

Correct Installation: Always install balls with proper alignment and tools. Wrong placement causes early wear.

Lubrication: Use the right lubricant in bearings or moving systems to reduce friction.

Regular Inspection: Check for wear, cracks, or surface changes.

Avoid Contamination: Dirt, sand, or dust in the system can damage the surface of the ball.

Follow Manufacturer Guidelines: Each supplier may give instructions for maximum load, temperature, or pressure.

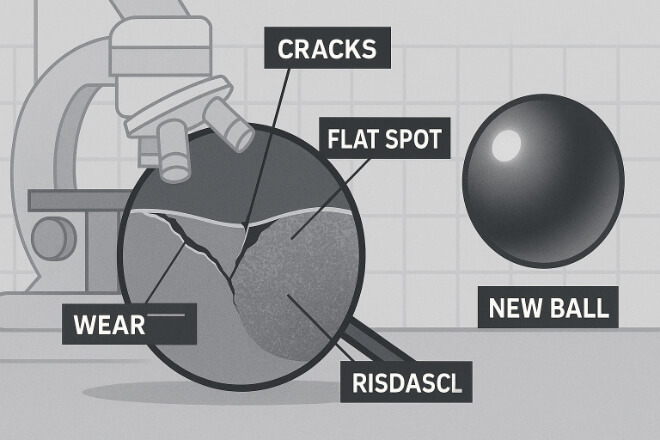

Maintenance and Replacement

Even though tungsten carbide balls are very durable, they are not indestructible. Decision-makers must plan for inspection and replacement.

Inspection Frequency: In critical systems (like oil rigs or chemical pumps), inspect every few weeks.

Signs of Wear: Flattened spots, surface cracks, or reduced accuracy.

Replacement Strategy: Always keep spare balls in stock. Replacing early prevents machine downtime.

Recycling: Tungsten carbide can be recycled, which reduces cost and supports sustainability.

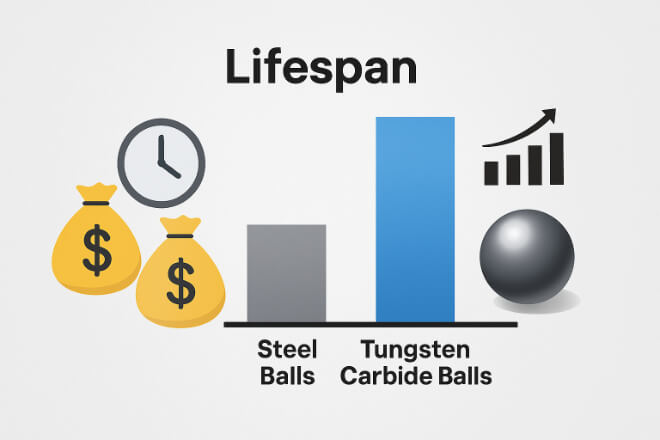

Cost Benefits of Tungsten Carbide Balls

Although the price of tungsten carbide balls is higher than standard steel balls, the long-term benefits are much greater.

Longer Life – 5x to 10x longer than steel balls

Reduced Downtime – Less frequent replacement means more production hours

Lower Maintenance Costs – Fewer failures save labor and repair expenses

Better Performance – Machines run smoother and more efficiently

For decision-makers, this means a better return on investment.

Case Examples

1). Oil & Gas Drilling

Companies use tungsten carbide balls in mud motor valves. Even in harsh drilling mud, the balls seal perfectly and reduce tool failure.

2). Automotive Bearings

High-performance engines use carbide balls in turbocharger bearings. This improves speed and heat resistance.

3). Chemical Pumps

Carbide balls are used in valve systems to prevent leaks of aggressive chemicals, increasing safety.

How to Source Tungsten Carbide Balls

When buying, decision-makers should consider:

Supplier Reputation – Choose trusted suppliers with ISO certifications.

Local Stock – A supplier with local inventory can reduce lead time.

Customization – Some industries need special coatings or sizes.

Technical Support – Suppliers offering testing, consulting, and after-sales service bring extra value.

For more detailed supplier information, you can visit Retopz.com where tungsten carbide suppliers and manufacturers are listed.

Conclusion

Tungsten carbide balls are small but powerful components. They play a critical role in bearings, valves, flowmeters, and many other systems.

By choosing the right grade, installing correctly, and following maintenance practices, companies can gain strong benefits: longer tool life, reduced downtime, and improved efficiency.

For decision-makers, investing in tungsten carbide balls is not just about buying a product; it is about securing stable performance and lower long-term costs.

If you want to know more details about any company, please feel free to contact us.