In modern machining, speed and accuracy are everything. Whether you’re producing parts in a CNC workshop or managing large-scale manufacturing, the quality of your cutting tools directly affects your output, costs, and product quality.

That’s why more industries are switching from traditional tools to tungsten carbide cutting tools.

But what makes them so special? And how exactly do they improve your machining performance?

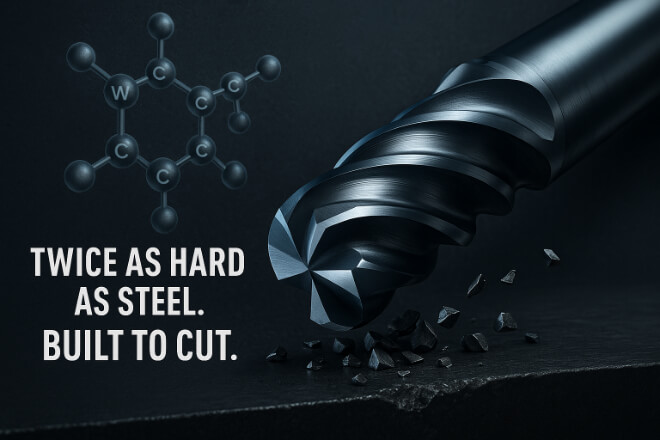

1. What Is Tungsten Carbide?

Tungsten carbide is a compound made from tungsten and carbon atoms. It’s extremely hard—nearly twice as hard as steel, and it can handle high temperatures without softening.

In fact, it’s one of the hardest materials used in manufacturing, only behind diamonds and a few advanced ceramics.

These properties make it perfect for cutting tools used in milling, turning, drilling, and grinding.

While high-speed steel (HSS) tools are cheaper, carbide tools stay sharper, cut faster, and last much longer—especially under tough machining conditions or with difficult materials.

2. Why Cutting Tools Matter in Machining

It’s easy to overlook cutting tools—they’re small and often just one part of a larger machine. But they play a huge role in how efficient and precise your operations are.

Using the wrong tool can result in:

Rough surface finishes

Increased tool breakage

Frequent machine downtime

Higher production costs

Excess material waste

Safety concerns from tool failure

The right tungsten carbide tool gives you:

Faster cycle times

Better part accuracy

Less tool wear and fewer replacements

Higher-quality results

Greater productivity from each machine shift

For shops focused on growth, profitability, and precision, cutting tools are not just accessories—they’re critical components of the entire machining system.

3. How Tungsten Carbide Improves Machining Efficiency

Let’s explore how carbide cutting tools specifically improve the efficiency of your machining process:

1). Faster Cutting Speeds

Tungsten carbide tools can handle much higher cutting speeds compared to steel tools. This allows you to:

Run machines at higher RPM

Use aggressive feed rates

Remove material faster

Complete jobs in less time

Especially in high-volume production environments, this increase in speed can translate into thousands of dollars in saved labor and machine hours each month.

2). Fewer Tool Changes

Carbide tools resist heat and abrasion much better than HSS tools. This leads to:

Less frequent tool changes

Reduced interruption of production

Lower risk of human error during tool change

Longer machine runtime per shift

Even though the initial cost of carbide is higher, the extended tool life and reduced handling requirements make them more cost-effective in the long run.

3). Consistent Tool Performance

Carbide tools stay sharper longer and maintain consistent cutting performance—even when machining hard materials like titanium, Inconel, or tool steel. This consistency results in:

Uniform surface quality across large batches

Reliable part tolerances

Fewer scrap parts or rework

Stable process parameters over time

This is especially important in industries where quality must be guaranteed for safety or regulatory reasons.

4). Support for Automated Machining

As more factories shift toward automation and lights-out manufacturing, cutting tools must keep up. Carbide is ideal for these systems because:

It works at high speeds and feed rates

It resists tool deflection and heat damage

It supports robotic tool changers and unmanned cycles

It minimizes unexpected tool failures that can stop production

Carbide tooling is automation-ready, helping manufacturers improve output without increasing headcount.

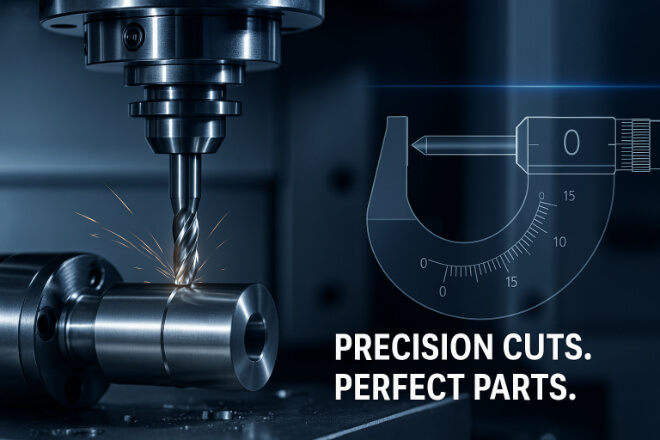

4. How Carbide Tools Improve Precision

Speed is great—but what about accuracy? Here’s where tungsten carbide truly shines.

1). Tighter Tolerances

Carbide’s hardness and stiffness allow for precise cuts with minimal tool deflection. This helps achieve:

Micron-level tolerances

Perfect part geometry

Better fitment with other components

Consistent results from part to part

2). Cleaner Surface Finishes

A sharp carbide tool generates less vibration and tearing at the cut surface. This results in:

Smoother finishes

Less need for post-processing or polishing

Better coating adhesion for plated or painted parts

Enhanced aesthetics and surface integrity

3). Less Heat-Related Distortion

Tungsten carbide dissipates heat effectively and resists softening at high temperatures. That means:

Less risk of thermal warping

More accurate cuts on thin or heat-sensitive parts

Extended tool life in dry or semi-dry machining

Reduced thermal load on your CNC spindle

In industries where even small inaccuracies matter, carbide is the preferred material for reliable results.

5. Real-World Example: CNC Shop Output Comparison

Here’s a quick example showing the difference in performance between HSS and carbide tools:

| Tool Type | Cycle Time (mins) | Parts per Shift | Surface Finish Quality | Tool Life |

|---|---|---|---|---|

| HSS End Mill | 12 | 40 | Medium | 3–5 hours |

| Carbide End Mill | 5 | 100+ | Excellent | 15–20 hours |

Result: The shop more than doubled its daily output, improved surface quality, and reduced tool replacements—all by switching to tungsten carbide.

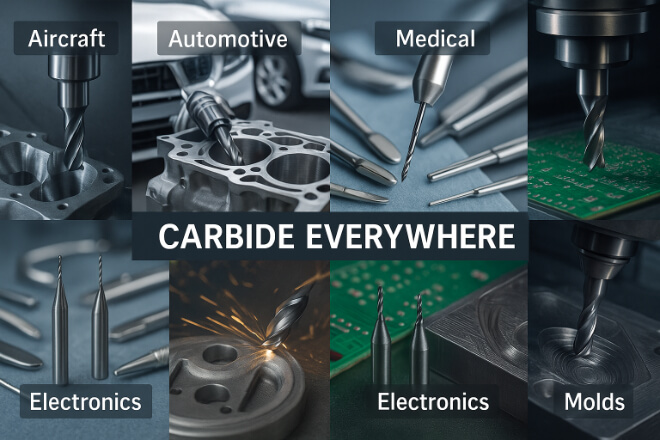

6. Common Applications That Benefit Most

Tungsten carbide cutting tools are trusted across many industries. Here’s a look at where they shine the most:

1). Aerospace

Precision cutting of titanium and superalloys

High-speed milling of turbine blades

Maintaining tolerances under high thermal loads

2). Automotive

Machining engine blocks, brake components, and gears

Supporting large-scale production with minimal tool wear

Enhancing finish quality for critical fits

3). Medical Devices

Creating surgical implants with strict tolerances

Micro-drilling fine holes in stainless or cobalt-chrome

Ensuring consistent, burr-free cuts

High-precision routing and drilling

Clean cuts on delicate copper and composite materials

Maintaining accuracy at miniature scales

5). Mold and Die

Engraving hardened steel and tool steels

Supporting both roughing and fine finishing operations

Reducing tool breakage in deep cavities

6). Oil and Gas

Cutting corrosion-resistant alloys

Maintaining tool integrity in harsh drilling conditions

Improving uptime in field machining

7). Woodworking

Cutting MDF, plywood, and composites

Longer edge life even with abrasive boards

Cleaner finish with fewer passes

8). Watchmaking and Jewelry

Precision engraving of metals and gemstones

Ultra-fine detail milling and micro-shaping

Delicate work with maximum control

7. What to Consider When Choosing Carbide Tools

To unlock full performance, you need the right carbide tool for your application. Focus on:

Material compatibility – Some coatings work better with steel, others with aluminum

Geometry – Choose correct flute count, rake angle, and corner radius for each task

Machine capability – Match tool design with spindle power, RPM range, and rigidity

Coolant needs – Some tools are optimized for dry machining, others for flood coolant

Coating type – TiAlN, AlCrN, DLC, and others improve heat resistance and chip control

8. Is Tungsten Carbide Worth the Investment?

In one word: yes.

While the initial price of carbide tools is higher than HSS, the long-term benefits are hard to ignore:

Reduced tooling cost per part

Higher machine uptime

Better quality control

Lower scrap and rework rates

Faster ROI on equipment and labor

Carbide tools pay for themselves quickly, especially in competitive industries where efficiency and quality make or break a business.

Final Thoughts

If your shop is aiming to cut faster, reduce waste, and improve part accuracy, tungsten carbide cutting tools are the answer.

Their strength, speed, and precision make them a smart upgrade for almost every machining operation.

Whether you’re milling aluminum, drilling titanium, or cutting plastics, carbide will help you do it better—and smarter.

If you want to know more details about any company, please feel free to contact us.