Introduction

Sustainability is more than a trend—it’s the future of manufacturing. As factories and industries work to reduce waste, save energy, and lower emissions, they are looking for tools and technologies that can help. One of the most important tools for this goal is the tungsten carbide cutting tool.

In this article, we explain how tungsten carbide cutting tools support sustainable manufacturing. We’ll show how they reduce waste, save energy, and increase efficiency. This helps companies become more eco-friendly while also saving money.

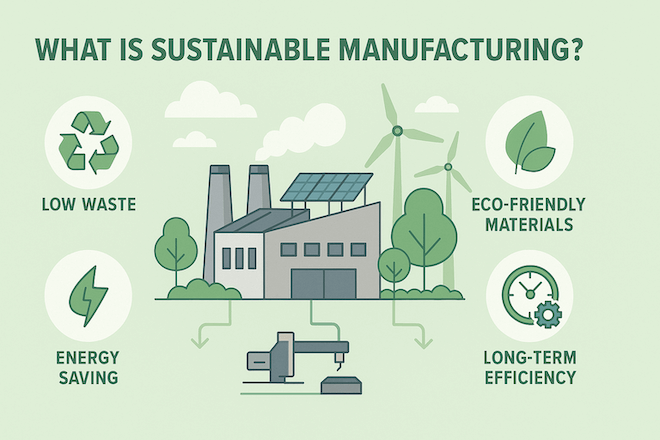

What Is Sustainable Manufacturing?

Sustainable manufacturing means making products in ways that:

Use fewer natural resources

Create less waste

Save energy and water

Cause less pollution

Support long-term business and environmental goals

To do this, factories must use better materials, smarter machines, and more efficient tools—like tungsten carbide tools.

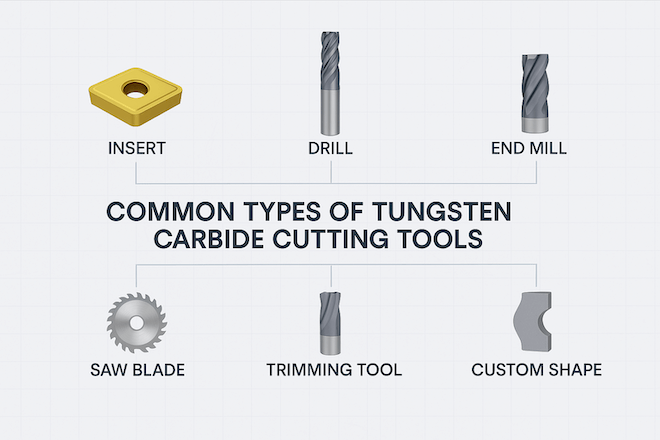

What Are Tungsten Carbide Cutting Tools?

Tungsten carbide is a very hard material made from tungsten (W) and carbon (C). It is stronger and more durable than steel. That’s why many cutting tools—such as drills, end mills, inserts, and saw blades—are made from it.

These tools are used in metalworking, woodworking, mining, oil & gas, aerospace, and many other industries.

Explore products like:

How Do Tungsten Carbide Tools Help the Environment?

Let’s look at the key ways that tungsten carbide cutting tools support green manufacturing:

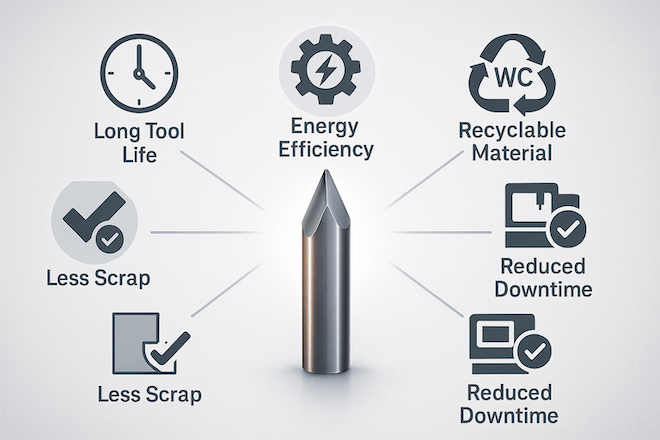

1. Longer Tool Life = Less Waste

Tungsten carbide tools last much longer than regular steel tools. This means:

Fewer tools are thrown away

Less raw material is needed

Less packaging and shipping

This helps reduce solid waste in factories and landfills.

2. Better Efficiency = Less Energy

Because carbide tools stay sharp longer, they cut faster and more precisely. This leads to:

Shorter machine cycles

Less rework or scrap

Lower energy use per part

Over time, this greatly reduces the carbon footprint of production.

3. Less Frequent Tool Changes = Lower Emissions

Changing tools often means stopping machines, using electricity, and creating heat. Since carbide tools don’t need to be changed as often, you save:

Electricity

Compressed air

Operator time

Fewer tool changes = less downtime and lower greenhouse gas emissions.

4. Recyclability of Carbide

Tungsten carbide is 100% recyclable. Old tools can be:

Collected

Reprocessed

Turned into new tools

This supports a circular economy and reduces the need to mine new tungsten ore.

👉 Retop supports carbide recycling as part of our commitment to sustainability.

5. Higher Quality = Less Scrap

Carbide tools deliver cleaner, smoother, and more accurate cuts. This improves part quality and reduces:

Defects

Rejects

Scrap materials

Reducing scrap helps save raw materials and energy, especially in industries like aerospace and automotive where tolerances are tight.

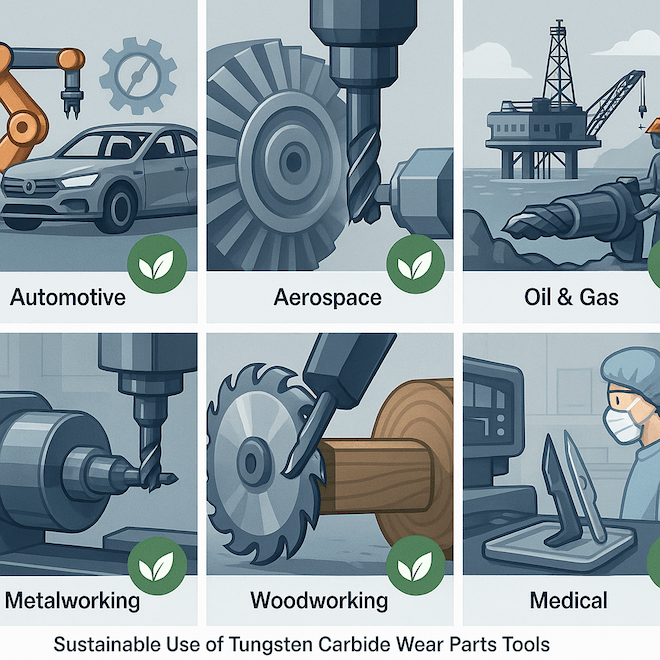

Industry Examples: Sustainable Use of Carbide Tools

Let’s see how different industries use carbide cutting tools for sustainability:

| Industry | Sustainable Benefit |

|---|---|

| Automotive | Fewer tool changes = lower energy per part |

| Aerospace | Precision cuts = less titanium waste |

| Oil & Gas | Durable tools = less downtime and transport |

| Metalworking | Clean cuts = less scrap and smoother finishes |

| Woodworking | Longer life blades = fewer trees wasted |

👉 See more uses on our Carbide Industry Applications page at www.retopz.com.

Why Choose Retop for Sustainable Carbide Solutions?

At Retop, we are proud to support green manufacturing. Our tools are:

Made with high-quality, recyclable materials

Designed for long life and efficiency

Backed by 14+ years of experience

Exported to 50+ countries

Used in industries focused on sustainability

We offer custom carbide tool solutions to help you meet your environmental goals without sacrificing performance.

👉 Explore our custom carbide tools and join the movement toward a cleaner future.

Tips for Using Carbide Tools More Sustainably

To get the most out of your tungsten carbide cutting tools, try the following:

Use the right tool for the material

Choose coated tools for extra wear resistance

Keep tools sharp and clean

Use smart machining strategies

Recycle worn-out tools with a certified vendor

Looking for help choosing the right tool? Contact Retop’s technical team for expert support.

Conclusion

Tungsten carbide cutting tools are not only strong and long-lasting—they are also an important part of sustainable manufacturing. By reducing waste, saving energy, and supporting recycling, these tools help factories run cleaner and more efficiently.

If your company wants to reduce its environmental impact while keeping production high, tungsten carbide tools from Retop are a smart investment.

Start building a greener future with better tools—today.