Tungsten carbide cutting tools are essential in modern manufacturing. They are known for being hard, tough, and reliable in high-speed machining.

But not many decision-makers take time to understand what makes these tools perform so well. One key factor is microstructure—the tiny internal structure of the tungsten carbide material.

In this article, we’ll explain what tungsten carbide microstructure is, how it affects tool performance, and what to look for when choosing the right tool for your machining needs.

What Is Tungsten Carbide Microstructure?

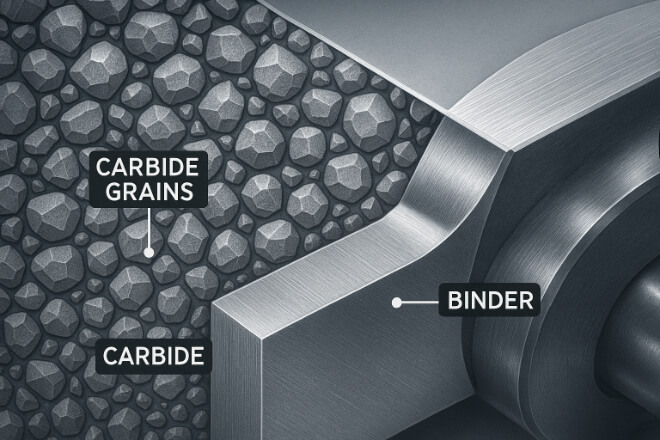

Tungsten carbide is a composite material made of two parts:

Tungsten carbide grains (hard particles that do the cutting)

Cobalt binder (a metal that holds the grains together)

The microstructure refers to how these grains and binder are arranged on a microscopic level. This includes:

Grain size (fine or coarse)

Grain shape (rounded or angular)

Binder content (% of cobalt)

Distribution (how evenly materials are mixed)

Just like how the texture of concrete affects how strong a building is, the microstructure affects how well a cutting tool performs.

Why Does Microstructure Matter?

The microstructure of tungsten carbide has a direct effect on the tool’s:

Heat resistance

Edge strength

Even if two tools look the same, their internal structure can make one last much longer or perform better under stress.

A fine-grained carbide might be better for high-precision tasks, while a coarse-grained one might survive better in heavy-duty applications.

That’s why understanding microstructure helps you choose the right tool for the job.

Grain Size: Fine vs. Coarse

One of the biggest influencers of tool behavior is grain size.

| Grain Type | Characteristics | Ideal Use Case |

|---|---|---|

| Fine-Grain | Very hard, sharp edges, smooth finish | High-speed finishing, small parts |

| Medium-Grain | Balanced hardness and toughness | General-purpose machining |

| Coarse-Grain | Tougher, resists chipping, good shock resistance | Interrupted cuts, heavy roughing |

Fine-grain carbide (0.2 – 0.5 μm) gives excellent wear resistance and edge sharpness, perfect for high-speed steel or aluminum cutting.

Coarse-grain carbide (>1.5 μm) offers better toughness. It’s great for rough milling, casting work, or cutting hard materials where the tool faces strong forces.

Binder Content and Its Role

Cobalt binder holds the tungsten carbide grains together. The more cobalt you have, the tougher the tool. But too much binder reduces hardness.

| Cobalt % | Hardness | Toughness | Best For |

|---|---|---|---|

| Low (5–6%) | Very hard | Brittle | Finishing, high-speed applications |

| Medium (8–10%) | Balanced | Balanced | General-purpose cutting |

| High (12–15%) | Lower hardness | Very tough | Interrupted cuts, heavy milling |

So, if you’re cutting smooth materials at high speed, go for a tool with low cobalt.

If you need the tool to absorb shock (like in cast iron cutting), you’ll need a higher cobalt grade.

The Impact on Wear Resistance

Wear resistance is one of the biggest reasons shops use tungsten carbide. Microstructure directly affects how well the tool handles wear.

Fine grains = more grain boundaries = more wear resistance

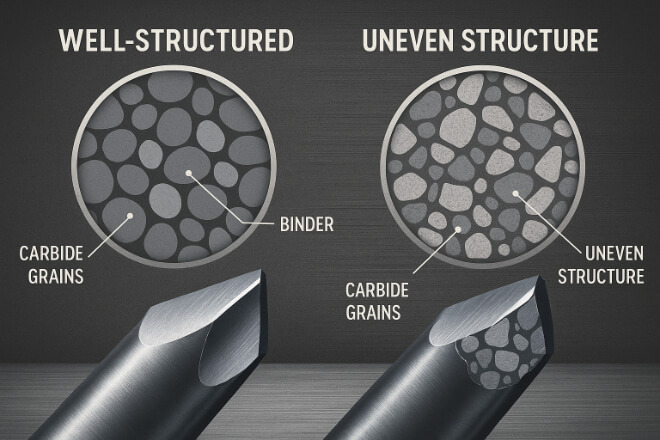

Even distribution of grains and binder = uniform wear

Correct cobalt ratio = balance of toughness and hardness

Tools with poor microstructure (like uneven grain sizes or binder pools) will wear out faster, chip more often, or give uneven finishes.

Microstructure and Heat Resistance

Heat is a major enemy in machining. The wrong tool material can soften or crack when exposed to high temperatures.

A microstructure designed for heat resistance will include:

Thermally stable grains

Coatings (like TiAlN) that work well with the carbide base

Tight grain bonding to prevent cracks

Fine-grained carbide combined with the right coating can handle speeds up to 300–400 m/min in steel cutting—without softening.

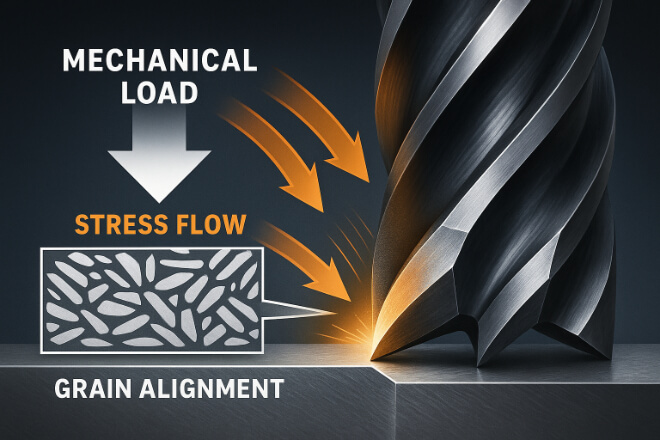

Tool Edge Strength and Microstructure

Edge strength is about how well the tool keeps its cutting edge under load.

For tools with sharp corners or complex shapes, microstructure becomes even more important.

Fine grains help retain edge sharpness

Even microstructure prevents weak points

Low porosity ensures durability

When cutting hard or abrasive materials like stainless steel or Inconel, a tool with strong edge retention makes all the difference.

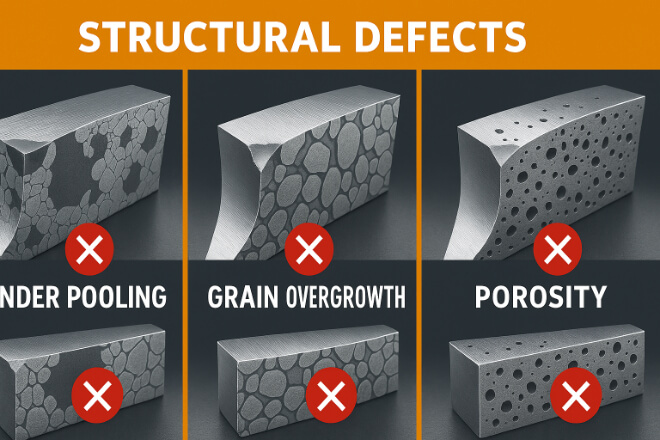

Common Microstructure Defects to Avoid

Bad microstructure equals bad performance. Watch out for:

Binder pooling – where cobalt gathers in spots. This weakens the tool.

Grain growth – oversized grains due to poor sintering. Lowers wear resistance.

Porosity – tiny air pockets that reduce strength and cause premature cracking.

Matching Microstructure to Application

Here’s a simple guide to choosing carbide microstructure based on your application:

| Application Type | Ideal Grain Size | Cobalt % | Notes |

|---|---|---|---|

| Finishing soft steel | Fine | 6–8% | High wear resistance needed |

| Rough milling cast iron | Coarse | 10–15% | Must absorb vibration |

| General CNC machining | Medium | 8–10% | Balanced toughness and hardness |

| Aerospace alloys (Inconel) | Fine | 6–7% | Needs heat and wear resistance |

| Wood & plastic | Fine | 5–6% | Clean finish required |

Choosing the wrong microstructure can result in tool failure, increased downtime, and scrap parts.

Why Supplier Matters for Microstructure

Not every supplier offers the same microstructure quality. Some low-cost manufacturers use recycled powders or skip proper sintering steps.

This causes defects, poor tool life, and inconsistent performance.

A good supplier will provide:

Microstructure control data

Grain size and cobalt % information

ISO certifications

Tool performance documentation

Final Thoughts

The microstructure of tungsten carbide is more than just a technical detail—it’s the heart of the tool.

It affects how long your tool lasts, how clean your cuts are, and how well your shop meets its productivity goals.

By understanding microstructure basics—grain size, binder ratio, and distribution—you can make smarter tool choices. And that means:

Fewer tool changes

Better part quality

Lower overall cost per part

Whether you’re machining aerospace parts or automotive components, carbide tools with the right microstructure will give you the edge you need.

Looking for consistent quality and expert guidance? Visit Retopz to explore high-performance tungsten carbide cutting tools tailored to your needs.