In heavy industries such as power generation, oil and gas, marine, and chemical processing, equipment is constantly exposed to heat, pressure, and mechanical shock.

If seals fail in these systems, the consequences are costly downtime, safety risks, and lower efficiency. To solve these challenges, companies rely on tungsten carbide seal rings.

This article explains how tungsten carbide seal rings are designed to resist thermal stress and mechanical shock, and why they are the trusted choice for high-demand industries.

What Are Tungsten Carbide Seal Rings?

Tungsten carbide seal rings are precision components used in pumps, compressors, and valves.

They are made from tungsten carbide, a material created by combining tungsten and carbon with a metallic binder (commonly cobalt or nickel).

The result is a material that is:

Extremely hard (close to diamond on the hardness scale)

Very strong under pressure

Resistant to heat and corrosion

Their role is simple but critical: provide a tight, reliable seal under extreme operating conditions.

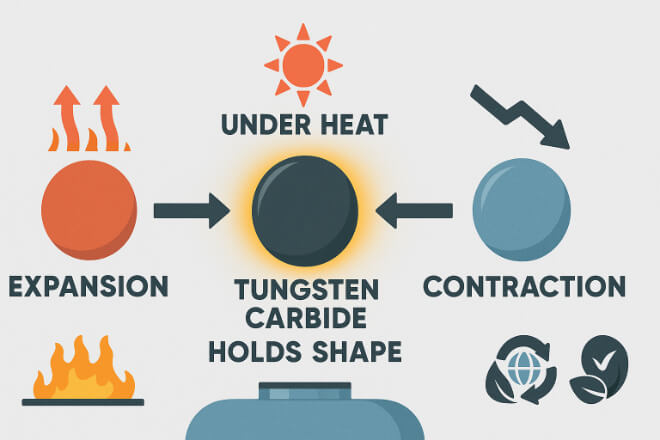

Understanding Thermal Stress in Seal Rings

Thermal stress occurs when materials expand and contract under changing temperatures. In industrial settings:

Pumps and turbines generate heat during continuous operation.

Sudden temperature changes (thermal shocks) can cause cracks.

Poor thermal resistance leads to seal failure and leakage.

Tungsten carbide is chosen because it retains strength and stability at high temperatures, reducing the risk of failure.

How Tungsten Carbide Seal Rings Resist Thermal Stress

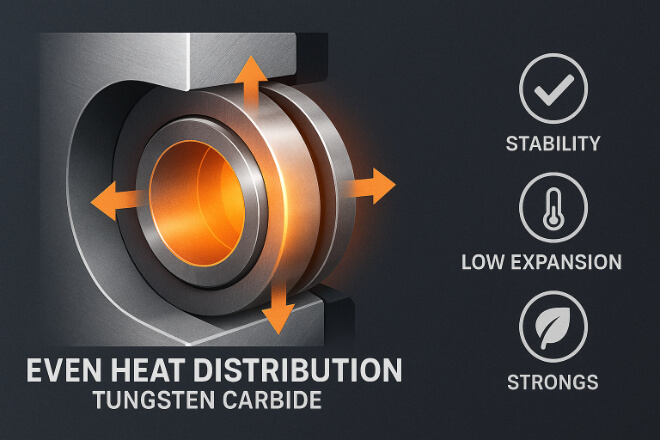

Tungsten carbide has unique material properties that protect it against heat:

Low Thermal Expansion – Prevents excessive size changes when temperatures rise.

High Thermal Conductivity – Helps spread heat evenly, reducing hot spots.

Stable Structure – Maintains hardness and strength even at high operating temperatures.

This means tungsten carbide seal rings do not crack or lose shape when exposed to repeated heating and cooling cycles.

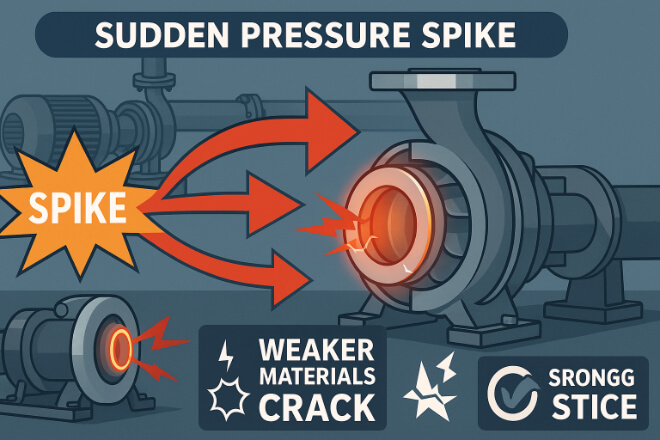

Mechanical Shock and Its Challenges

Mechanical shock happens when sudden pressure changes or impacts hit the system. In marine engines, turbines, or offshore pumps, this can occur from:

Rapid startup or shutdown

Sudden load changes

Water hammer or pressure spikes

When weaker materials are used, these shocks lead to cracks, deformation, or complete seal failure.

How Tungsten Carbide Seal Rings Resist Mechanical Shock

Tungsten carbide’s strength and toughness make it resistant to sudden impact:

High Compressive Strength – Withstands heavy loads without breaking.

Toughness from Binders – Nickel or cobalt bonding improves shock resistance.

Hard Surface – Resists chipping even when exposed to particle impact.

This combination ensures reliable sealing even under sudden system stress.

Industrial Applications That Demand Resistance

The ability to resist both thermal stress and mechanical shock makes tungsten carbide seal rings essential in:

Power Generation – Turbines and pumps exposed to extreme heat cycles.

Marine Industry – Propulsion systems and pumps exposed to seawater and sudden pressure changes.

Oil and Gas – Compressors and drilling equipment where pressure spikes are common.

Chemical Plants – Systems where hot, corrosive fluids cause both heat and shock stress.

In these industries, reliability is not optional—it is a requirement.

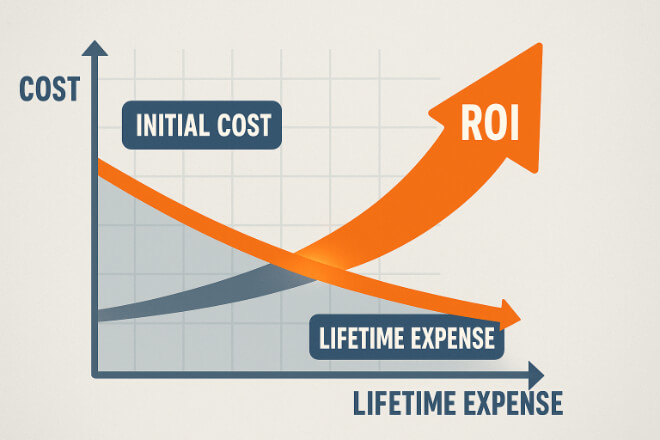

Cost vs Long-Term Value

While tungsten carbide seal rings cost more initially, their durability lowers total cost over time:

Fewer replacements due to longer life

Lower downtime costs from reduced failures

Safer operation, reducing risk of accidents

Higher ROI for companies focused on efficiency

For decision-makers, the choice is about long-term savings and reliability.

Best Practices to Maximize Life

To ensure seal rings provide maximum protection:

Install carefully to prevent misalignment and surface damage.

Inspect regularly for early signs of wear or cracking.

Use proper lubrication to reduce friction and overheating.

Choose the right grade (nickel-bonded for corrosion, cobalt-bonded for toughness).

With the right practices, tungsten carbide seal rings can perform reliably for years.

Sustainability and Recycling

Another benefit is that tungsten carbide seal rings can be recycled.

Worn rings are collected, processed, and reused, lowering material waste and supporting environmental goals.

Conclusion

Tungsten carbide seal rings resist thermal stress and mechanical shock better than most other materials.

With high hardness, toughness, and stability, they provide the durability and reliability needed in power plants, marine engines, oil and gas equipment, and chemical processing.

For decision-makers, investing in tungsten carbide seal rings means safer operation, reduced costs, and long-term value.

If you want to know more details about any company, please feel free to contact us.