Pumps are critical components in industries like oil and gas, power generation, chemical processing, and marine operations.

A single leak can cause costly downtime, environmental risks, and safety hazards. To avoid these issues, mechanical seals must be durable and reliable.

Tungsten carbide seal rings are one of the most trusted solutions for leak-free pump operation. This article explains their properties, advantages, applications, and best practices for decision-makers.

Why Leak-Free Pump Operation Matters

Prevents fluid loss → Protects resources and reduces waste.

Maintains efficiency → Pumps perform better without pressure loss.

Reduces maintenance costs → Fewer failures mean fewer repairs.

Protects the environment → Prevents spills of hazardous materials.

Ensures safety → Avoids dangerous leaks near operators or equipment.

Properties of Tungsten Carbide Seal Rings

Tungsten carbide is a compound of tungsten and carbon, bonded with cobalt or nickel. Its properties include:

Extreme hardness → Resists wear from friction and particles.

High compressive strength → Handles heavy loads without cracking.

Corrosion resistance → Works well with chemicals, seawater, and oils.

Thermal stability → Maintains sealing performance under high heat.

Dimensional stability → Ensures precise sealing over long periods.

These properties help pumps stay leak-free under tough conditions.

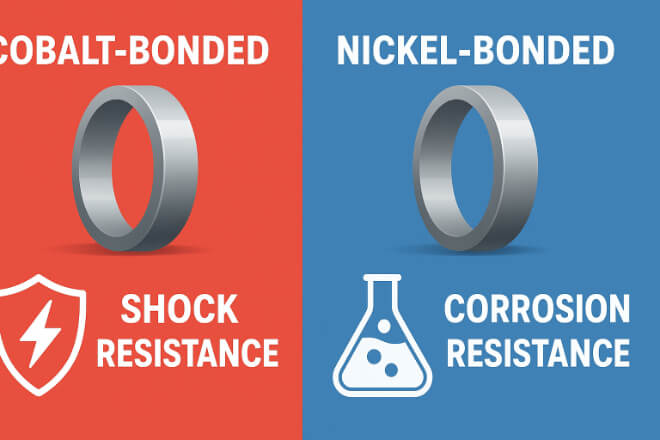

Cobalt-Bonded vs Nickel-Bonded Tungsten Carbide

1). Cobalt-bonded tungsten carbide

Best for vibration-heavy or high-shock pumps.

Common in oilfield and mining operations.

2). Nickel-bonded tungsten carbide

Superior corrosion resistance.

Ideal for chemical plants, marine pumps, and wastewater systems.

Choosing the right binder ensures long service life and reliable sealing.

Advantages Over Other Seal Materials

| Feature | Tungsten Carbide | Ceramic | Steel |

|---|---|---|---|

| Wear Resistance | Excellent for abrasives | Moderate | Poor |

| Corrosion Resistance | High (nickel grades) | Very good | Low |

| Toughness | High, resists shock | Low, brittle | Moderate |

| Thermal Performance | Excellent at high heat | Good | Moderate |

| Service Life | Long-lasting | Moderate | Short |

Applications in Pump Systems

Tungsten carbide seal rings are used in:

Chemical pumps → Handle aggressive fluids safely.

Marine pumps → Resist seawater corrosion.

Oil and gas pumps → Prevent leaks under pressure.

Wastewater pumps → Manage abrasive and corrosive fluids.

Power plant cooling pumps → Maintain leak-free operation for critical systems.

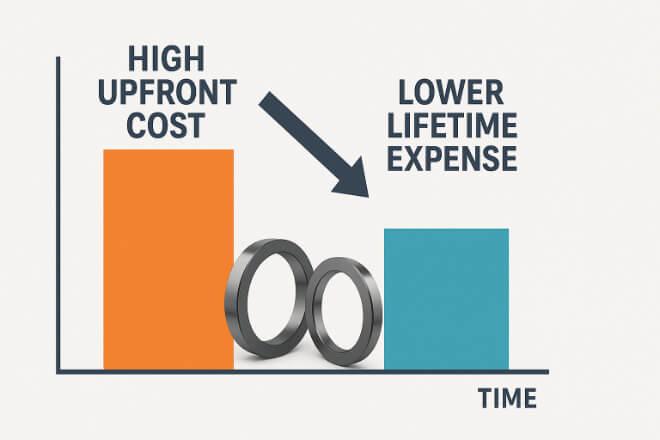

Cost vs Long-Term Value

While tungsten carbide rings cost more upfront:

Fewer replacements → Lower spare part costs.

Reduced downtime → Increases production efficiency.

Extended equipment life → Protects pump components.

Better ROI → Long-term savings outweigh initial price.

Environmental and Safety Benefits

Leak prevention → Avoids contamination and environmental damage.

Recyclable material → Supports sustainable practices.

Energy efficiency → Preventing leaks reduces wasted energy.

Best Practices for Leak-Free Performance

Select the right binder → Match to chemical and mechanical conditions.

Ensure proper installation → Avoid scratches or misalignment.

Use proper lubrication → Reduces friction and heat.

Inspect regularly → Catch wear early before leaks start.

Partner with reliable suppliers → Ensure material quality and correct specifications.

Key Takeaways for Decision-Makers

Tungsten carbide seal rings ensure leak-free pump operation under tough conditions.

Choosing the correct grade (nickel or cobalt) is critical for performance.

Their durability, recyclability, and efficiency lower costs and environmental risks.

Investing in tungsten carbide protects pumps and improves ROI.

Conclusion

For pumps in chemical plants, power stations, marine systems, and oilfields, tungsten carbide seal rings are a proven choice for preventing leaks.

Their hardness, corrosion resistance, and strength deliver long-term performance, reduced downtime, and environmental protection.

For decision-makers, selecting tungsten carbide is a strategic investment in safety, sustainability, and cost efficiency.

If you want to know more details about any company, please feel free to contact us.