Tungsten carbide wear parts are vital in industries like mining, oil and gas, metal cutting, and construction.

These parts are chosen for their hardness, wear resistance, and long life under extreme working conditions.

For decision-makers, understanding how tungsten carbide wear parts are manufactured helps in making better choices about suppliers, quality control, and costs.

This article explains the process in simple steps, showing how raw tungsten is turned into high-performance wear parts.

What Are Tungsten Carbide Wear Parts?

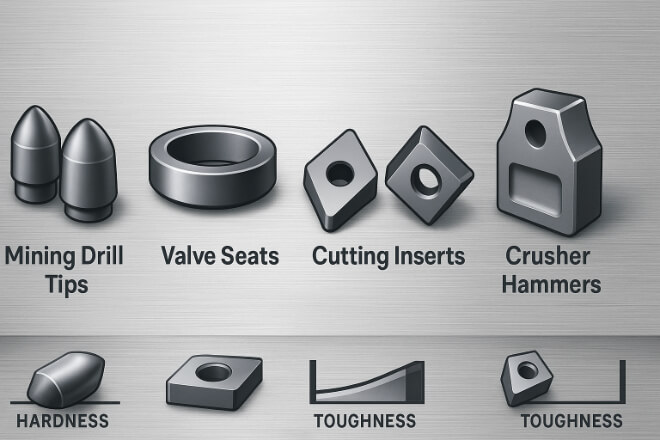

Tungsten carbide wear parts are components made to resist abrasion, impact, and high temperature.

Examples include mining drill tips, crusher hammers, valve seats, and cutting inserts.

They are created using a special method called powder metallurgy. This allows precise control over hardness, toughness, and grain size.

Raw Materials Selection

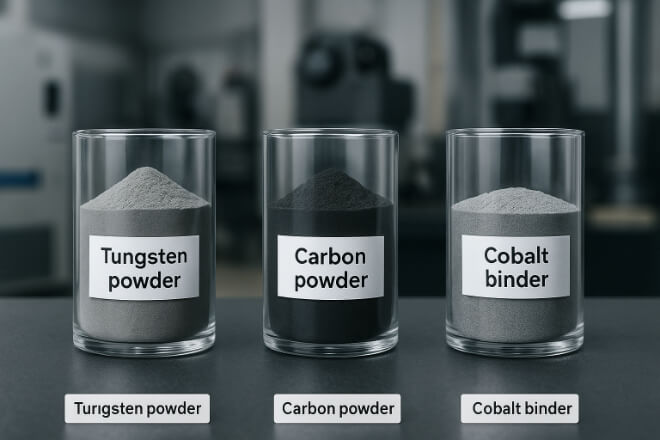

The two main materials are:

Tungsten (W) — a hard, dense metal.

Carbon (C) — combines with tungsten to form tungsten carbide (WC).

A metallic binder, usually cobalt (Co) or nickel (Ni), is added to improve toughness.

Key factors for quality:

Purity of tungsten and carbon powders.

Consistent particle size for even performance.

Correct binder ratio.

Powder Preparation

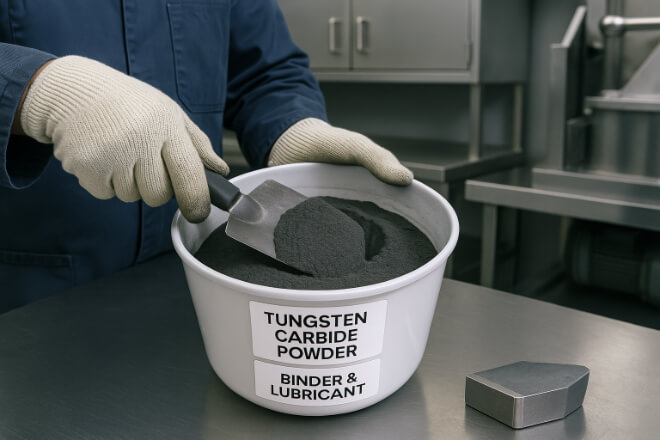

The tungsten and carbon powders are measured accurately.

They are mixed with the binder powder and sometimes small amounts of grain growth inhibitors.

Mixing is done in ball mills or mixers to ensure:

Even distribution of particles.

Consistent chemical composition.

Carburization

Carburization is the process where tungsten powder is heated with carbon to create tungsten carbide (WC).

This is done in a high-temperature furnace under a controlled atmosphere to prevent oxidation.

Powder Blending

After carburization, the WC powder is mixed again with binder powder and lubricants to prepare for shaping.

This step ensures the mechanical properties meet the intended application — for example, high hardness for cutting tools or more toughness for impact tools.

Compaction / Pressing

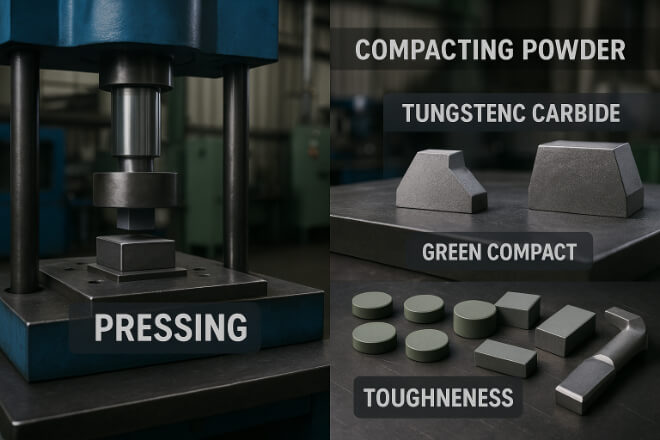

The blended powder is compacted into the desired shape using:

Uniaxial pressing — for simple shapes.

Cold Isostatic Pressing (CIP) — for complex shapes and uniform density.

The compacted part is called a green compact — it is still fragile at this stage.

Pre-Sintering (Optional)

Some parts undergo pre-sintering at a lower temperature to remove lubricants and improve handling strength before final sintering.

Sintering

Sintering is the most critical stage.The green compact is heated in a vacuum or controlled atmosphere furnace at temperatures up to 1,450–1,500°C.

During sintering:

Binder melts and fills gaps between carbide particles.

Part shrinks by about 20% but gains full strength and density.

Post-Sintering Finishing

After sintering, the part is extremely hard but may require finishing. Common finishing methods:

Grinding — for precise dimensions.

Polishing — for smooth surfaces.

Coating (e.g., TiN, TiAlN) — for extra wear resistance.

Quality Control

Each part goes through strict inspection:

Hardness testing (Rockwell or Vickers).

Density check to ensure no porosity.

Dimensional accuracy verification.

| Inspection Type | Purpose | Tools Used |

|---|---|---|

| Hardness Test | Verify wear resistance | Rockwell / Vickers Tester |

| Density Check | Ensure structural integrity | Archimedes Method |

| Dimensional Check | Ensure fit in machinery | CMM (Coordinate Measuring Machine) |

Applications of Tungsten Carbide Wear Parts

Tungsten carbide wear parts are used in:

Mining — drill bits, crusher components.

Oil and Gas — valve seats, flow control tools.

Metal Cutting — end mills, inserts.

Construction — road milling tools.

Agriculture — plough and tillage parts.

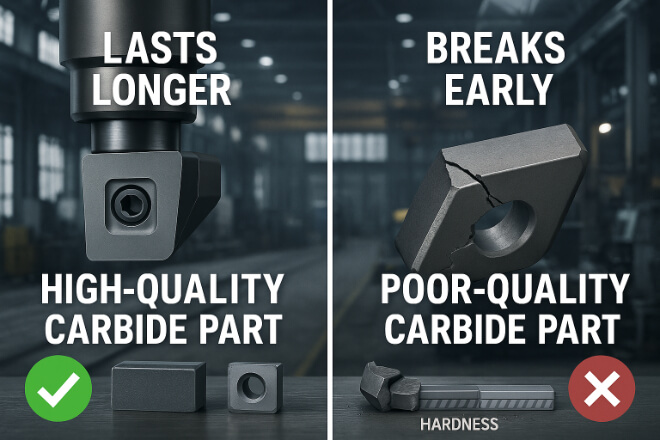

Why Manufacturing Quality Matters

For decision-makers, the cost of downtime caused by poor-quality parts is often higher than the purchase price.

Choosing a manufacturer with tight process control, modern equipment, and strict QC standards ensures better performance and longer service life.

Conclusion

Tungsten carbide wear parts are made through precision powder metallurgy, from raw tungsten and carbon to sintered, finished products.

Every step — from material selection to final inspection — impacts performance in real-world industrial environments.

For companies in mining, oil and gas, construction, and manufacturing, working with a reliable tungsten carbide supplier ensures better productivity, lower maintenance, and higher return on investment.

If you want to know more details about any company, please feel free to contact us.