In today’s competitive manufacturing environment, we are always looking for ways to cut faster, last longer, and produce better-quality parts.

Tungsten carbide cutting tools have already earned their place as a go-to solution for high-performance machining.

But the innovation hasn’t stopped. In recent years, there have been exciting advances in tungsten carbide tool design and materials that push productivity even further.

In this article, we’ll explore the latest trends in carbide cutting tools—how new materials, coatings, microstructures, and design strategies are reshaping performance.

If you’re a decision-maker in the machining or tool selection process, these updates can help you make smarter investments and stay ahead of your competition.

1. Why Innovation Matters in Tungsten Carbide Tools

The demands of modern machining are changing quickly. Manufacturers now need tools that can handle harder materials, higher speeds, and tighter tolerances—with less downtime and more efficiency.

That’s why innovation in carbide cutting tool materials is crucial. Every small improvement in grain structure, cobalt content, or tool geometry can lead to:

Longer tool life

Better surface finish

Higher cutting speeds

Lower cost per part

This is especially important in industries like aerospace, automotive, and medical manufacturing, where precision and performance are critical.

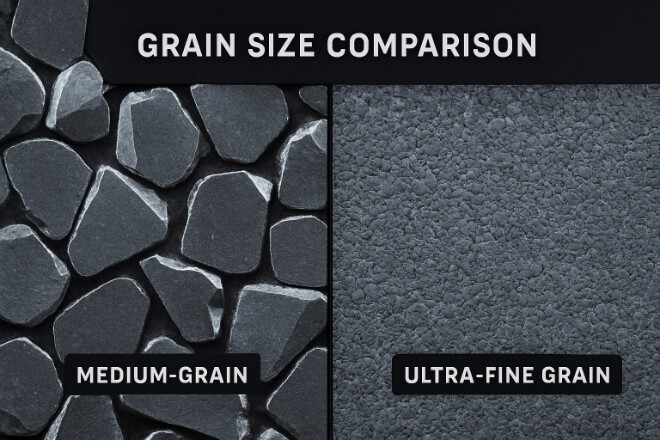

2. Improved Grain Structures: Fine vs. Ultra-Fine

One of the biggest breakthroughs in tungsten carbide materials is the control of grain size. Traditionally, carbide was made with medium or coarse grains.

Today, manufacturers are shifting to fine and ultra-fine grain carbide for certain applications.

Why grain size matters:

By using ultra-fine grains, modern tools can stay sharper for longer and resist edge wear—perfect for high-speed finishing.

On the other hand, hybrid or dual-grain carbide mixes help balance both hardness and toughness in one tool.

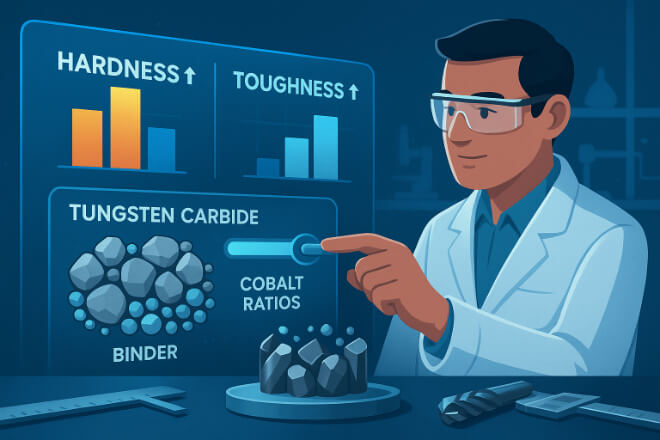

3. Advanced Binder Formulas and Cobalt Ratios

Tungsten carbide tools use cobalt as a binder to hold the grains together. Adjusting the cobalt content can greatly affect tool performance.

Lower cobalt = higher hardness

Higher cobalt = greater toughness and crack resistance

Some manufacturers are now using custom binder formulas or even replacing cobalt with other elements to improve strength and reduce environmental concerns.

These innovations also help tools handle aggressive cutting or interrupted machining with less risk of failure.

4. Next-Generation Coatings for Extreme Performance

Coatings are just as important as the carbide base itself. Modern tool coatings can double or triple tool life by reducing friction, managing heat, and protecting against wear.

Here are some of the latest coating types used in carbide tools:

| Coating Type | Key Benefits | Ideal Use |

|---|---|---|

| TiAlN (Titanium Aluminum Nitride) | High heat resistance, strong wear protection | High-speed steel, alloy machining |

| AlTiN | Superior oxidation resistance, excellent in dry cutting | Aerospace, stainless steel |

| DLC (Diamond-Like Carbon) | Ultra-smooth, anti-stick, good for non-ferrous metals | Aluminum, plastics |

| CVD Diamond | Extreme hardness, great for abrasive materials | Graphite, composites, ceramics |

By choosing the right coating, users can significantly reduce downtime and improve machining quality.

5. Smart Tool Geometries and Chip Control

Tool shape isn’t just about how it looks—it affects chip flow, vibration, and heat dissipation. Innovative carbide tools now feature:

Variable helix angles to reduce chatter

Asymmetric flute designs to improve chip evacuation

Reinforced cutting edges for longer wear

Custom geometries can be designed based on the material you’re cutting and the type of finish you need. Some carbide suppliers even offer simulation-based design to fine-tune tool shapes before production.

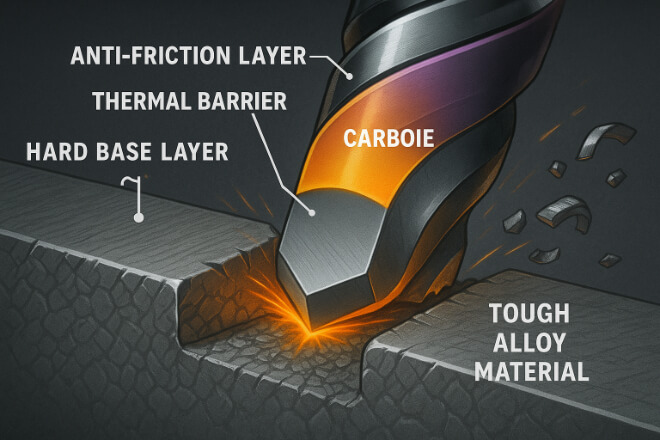

6. Hybrid and Multi-Layer Coatings

Traditional coatings are one layer thick. Today, more advanced carbide tools use multi-layer coatings to combine different properties in one tool.

For example:

A hard base layer gives protection from wear

A top anti-friction layer reduces heat and chip sticking

Some include thermal barrier layers to handle dry machining

These hybrid systems let tools perform well across various materials and cutting conditions.

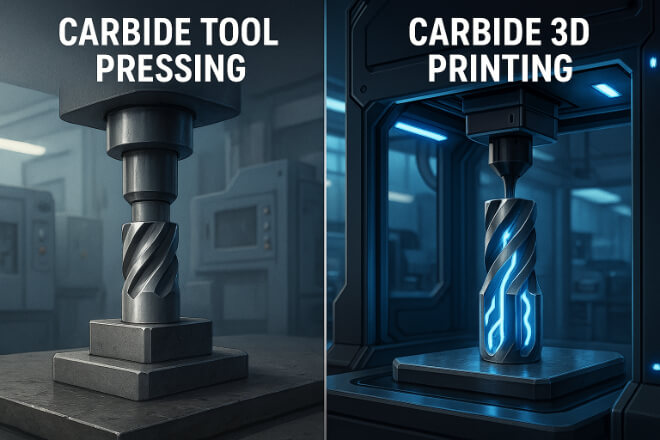

7. Additive Manufacturing and Pressing Techniques

While carbide tools are typically made by powder pressing and sintering, new production methods are emerging.

Additive manufacturing (3D printing) of carbide is still in its early stages but has potential for:

Creating complex shapes with internal coolant channels

Reducing material waste

Faster prototyping of custom tools

Meanwhile, advanced powder compaction methods are improving consistency and density in pressed carbide blanks, leading to stronger, more reliable tools.

8. Embedded Sensors and Smart Tooling (Emerging)

Though not yet mainstream, some cutting-edge projects involve embedded sensors in carbide tools. These sensors can measure:

Tool temperature

Cutting force

Vibration or wear signals

Smart tooling could help manufacturers monitor tool wear in real time and replace tools before failure—reducing scrap and avoiding machine damage.

While this tech is still in R&D or limited to specialized industries, it represents the future of intelligent carbide tooling.

9. Environmentally Friendly Carbide Materials

With increased focus on sustainability, some toolmakers are developing green carbide options, including:

Recycled tungsten carbide powder

Low-cobalt or cobalt-free formulas

Water-based binders and non-toxic additives

These tools reduce environmental impact while still offering top performance.

For companies working toward ESG goals, using sustainable carbide tooling is a small change that supports larger commitments.

10. Customization and Application-Specific Tools

Finally, one of the most valuable innovations isn’t a material—it’s the ability to customize tools to specific needs. Leading carbide suppliers now offer:

Made-to-order tools based on part geometry

Specialized coatings for exotic materials

Quick turnaround on small-batch custom designs

For example, a cutting tool for machining titanium implants might require a different grade and shape than one used in cutting aluminum engine blocks.

With better access to customization, manufacturers can fine-tune tooling for maximum performance.

Final Thoughts

Innovation in tungsten carbide cutting tools isn’t just about technology—it’s about solving real-world problems on the shop floor.

Whether it’s new coatings that reduce tool changeovers or microstructure tweaks that extend tool life, these advances offer better productivity, higher precision, and lower costs.

If you’re in charge of tool purchasing or production planning, staying updated on the latest innovations can help you:

Choose better tools

Improve machining results

Reduce operational risks

Stay ahead of competitors

The future of cutting is smarter, harder, and more efficient. Make sure your tool choices are moving with it.

If you want to know more details about any company, please feel free to contact us.