炭化タングステン工具の密度について

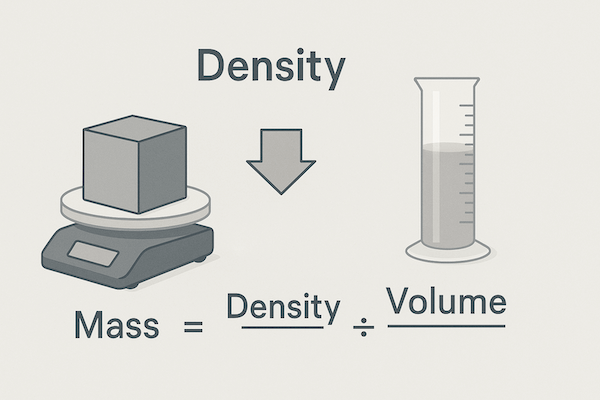

密度とは?密度とは、物質の単位体積あたりの質量を表す基本的な物理的特性です。通常、立方センチメートルあたりのグラム数(g/cm³)または立方メートルあたりのキログラム数(kg/m³)で表されます。式はシンプルです。密度=質量÷体積。この特性は、強度、耐摩耗性、熱伝導性、そして過酷な環境における全体的な性能に影響を与えるため、材料選定において重要な役割を果たします。エンジニアリング材料において密度が重要な理由とは?産業用途において、密度は単なる数値ではなく、圧力、熱、機械的応力下での材料の挙動に影響を与えます。高密度材料は、通常、以下の特性を備えています。強度と硬度の向上、耐摩耗性の向上、慣性モーメントの増加、そして[…]

炭化タングステン工具の破壊靭性について

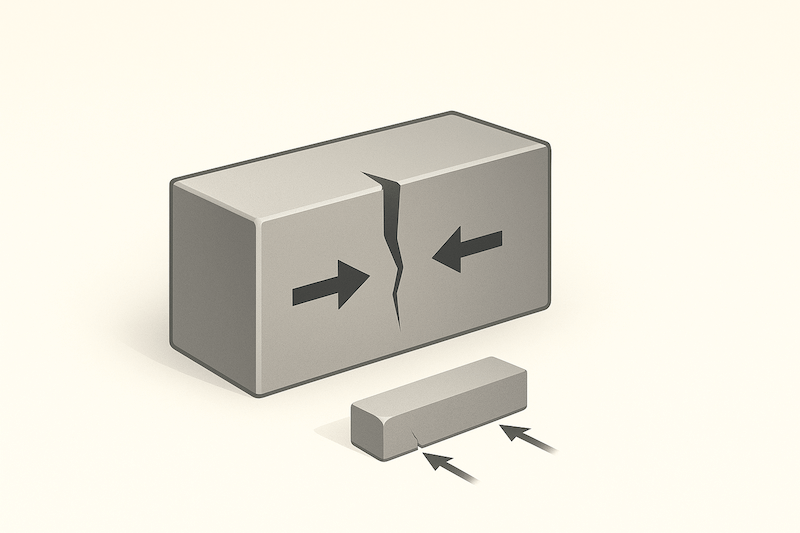

破壊靭性とは?破壊靭性とは、ひび割れの伝播に対する材料の抵抗力です。これは、欠陥や不具合が存在する状況で材料がどれだけ応力に耐えられるかを定量化するもので、特に脆性材料においては重要です。破壊靭性は通常K₁cと表記され、MPa·√mで測定されます。K₁c値が高いほど、微細なひび割れが存在する場合でも、材料が壊滅的な破損によく耐えることを意味します。なぜ破壊靭性は重要なのでしょうか?実際のエンジニアリングでは、欠陥のない材料は存在しません。機械加工、疲労、あるいは材料の制約により、微小なひび割れ、空隙、あるいは介在物がしばしば存在します。材料の破壊靭性が低いと、これらの小さな欠陥が応力下で成長し、急速に[…]

炭化タングステン工具の引張強度について

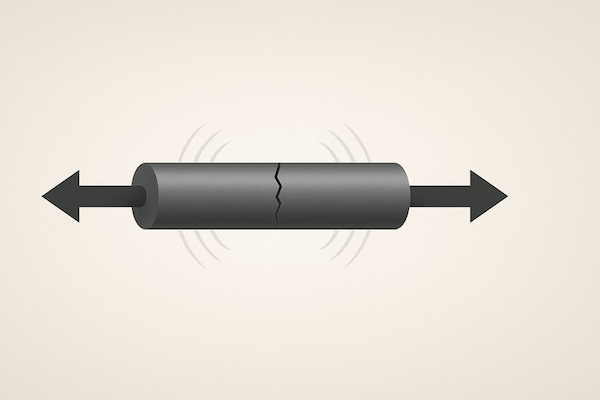

引張強度とは?引張強度とは、材料が引き伸ばされたり引っ張られたりした際に破断するまでに耐えられる最大応力を指します。これは基本的な機械的特性であり、通常はメガパスカル(MPa)または平方インチあたりの重量(psi)で測定され、材料の引き裂かれに対する抵抗力を表します。簡単に言えば、引張強度は、材料が破断するまでにどれだけの引張力に耐えられるかを示します。引張強度とその他の機械的特性の比較引張強度は、以下の特性と併せて議論されることがよくあります。圧縮強度(押し潰しや圧縮に対する抵抗力)、せん断強度(滑りに対する抵抗力)、そして横方向破断強度(TRS)は、一般的に超硬合金などの脆性材料で曲げ強度を近似するために用いられます。[…]

炭化タングステン工具の耐摩耗性を理解する

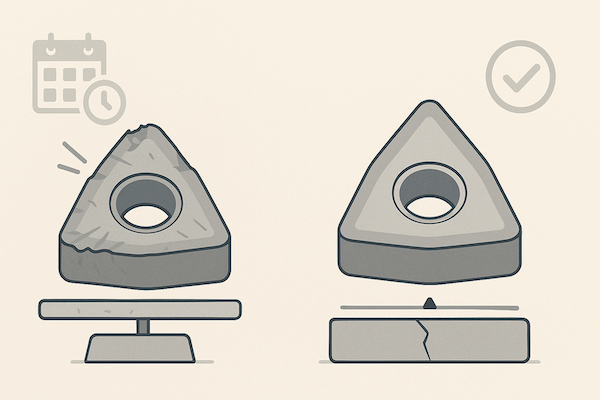

耐摩耗性とは?耐摩耗性とは、摩擦、摩耗、浸食、または他の材料との機械的接触によって引き起こされる表面の漸進的な損傷に対する材料の耐性を指します。高摩擦または高応力環境で使用される材料にとって、耐摩耗性は部品の耐用年数と性能に直接影響するため、非常に重要な特性です。耐摩耗性の高い材料は、長期間の使用や、より硬い表面や粗い表面との繰り返しの接触後でも、形状、表面の完全性、寸法を維持します。なぜ耐摩耗性が重要なのでしょうか?産業現場では、多くの部品や工具が継続的な移動、切削、研削、または衝撃にさらされています。十分な耐摩耗性がないと、表面は急速に劣化し、次のような問題につながります。精度の低下[…]