炭化タングステン工具の化学的安定性を理解する

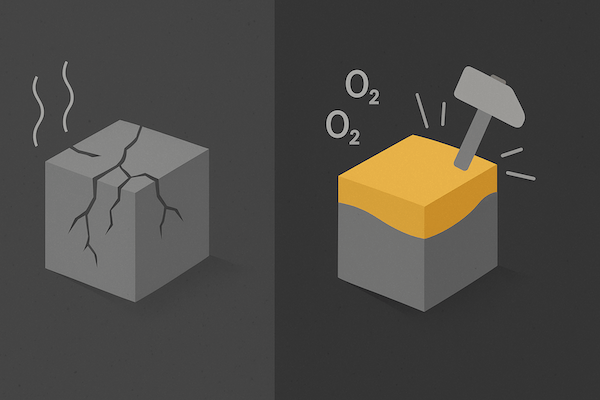

タングステンカーバイド工具は、その卓越した硬度と耐摩耗性で広く知られていますが、長期的な性能を維持するためには、化学的安定性という特性も同様に重要です。腐食性環境での使用、クーラントへの曝露、高温反応への耐性など、カーバイド工具は機能を維持するために化学的劣化に耐えなければなりません。この記事では、化学的安定性とは何か、タングステンカーバイド工具においてなぜ重要なのか、そして現代の工具材料にどのように組み込まれているのかを説明します。化学的安定性とは?化学的安定性とは、材料が周囲の環境との化学反応、特に酸化、腐食、酸、アルカリ、ガスとの反応に耐える能力を指します。切削工具や耐摩耗工具にとって、化学的安定性は構造的完全性を維持するために不可欠です。[…]

炭化タングステン工具における炭化物の組成を理解する

タングステンカーバイド工具は、極めて高い硬度、優れた耐摩耗性、そして長寿命で高く評価されていますが、これらの特性はどのようにして実現されているのでしょうか?その答えは、炭化物の組成にあります。炭化物組成とは、工具を形成するために使用される材料の特定の組み合わせを指し、工具の機械的、化学的、そして熱的性能に直接影響します。この記事では、炭化物組成とは何か、なぜそれが重要なのか、そして様々な元素がセメントカーバイド工具の挙動にどのように影響するのかを説明します。炭化物組成とは?炭化物組成とは、セメントカーバイド製品に含まれる材料の比率と種類を指します。これらの工具は、純粋なタングステンカーバイド(WC)のみから作られているのではなく、WCと以下の材料を混合した複合材料です。[…]

炭化タングステン工具製造における炭化粉末の理解

切削工具、採掘用ビット、工業用摩耗部品といった言葉を聞くと、強固で堅牢な高性能部品を思い浮かべることが多いでしょう。しかし、これらの驚異的な強度を持つ工具の起源は、実ははるかに微細な物質、すなわち超硬合金粉末にあります。この記事では、超硬合金粉末とは何か、どのように製造されるのか、そして、最も要求の厳しい産業用途で使用される超硬合金工具の製造においてなぜそれほど重要なのかを探ります。超硬合金粉末とは?超硬合金粉末とは、一般的に炭化タングステン(WC)粉末のことを指し、タングステン(W)と炭素(C)を高温で混合して作られる、灰色の微粒子セラミックのような物質です。この粉末は工具に直接使用されるのではなく、原材料として使用されます[…]

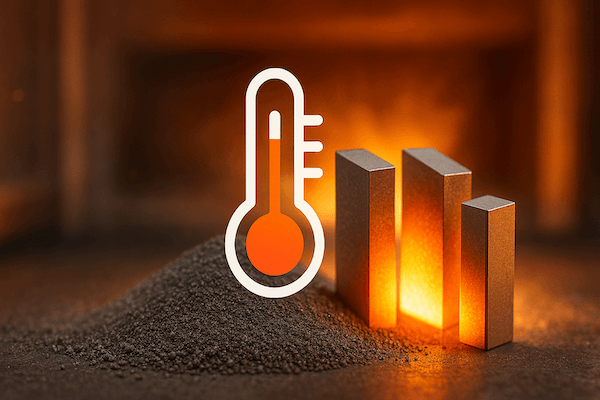

炭化タングステン工具製造における焼結温度の理解

焼結温度は、タングステンカーバイド(WC)工具の製造において重要な要素であり、硬度、強度、微細構造、そして全体的な性能に直接影響を及ぼします。この記事では、焼結温度の意味、硬質合金製造における焼結温度の役割、そして高品質の超硬工具の製造に精密な制御が不可欠な理由について考察します。https://www.retopz.com/wp-content/uploads/2025/06/Understanding-Sintering-Temperature-in-Tungsten-Carbide-Tool-Manufacturing.png 焼結温度とは?焼結温度とは、粉末材料が融点に達することなく圧縮・融合する高温を指します。タングステンカーバイド工具の場合、焼結プロセスでは通常、WC粉末と金属バインダー(通常はコバルト(Co)またはニッケル(Ni))の混合物を、1350℃~1500℃の温度範囲で加熱します。[…]

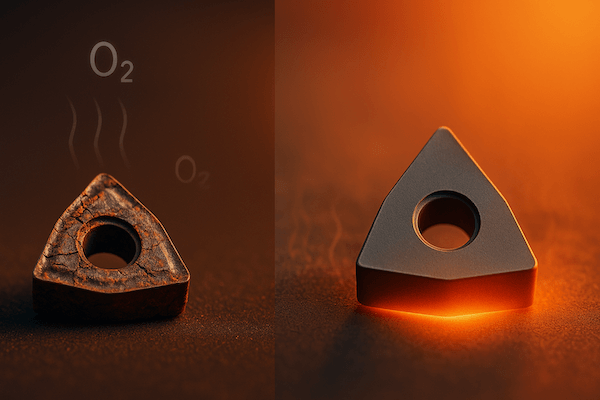

炭化タングステン工具の耐酸化性について

先端材料の世界において、耐酸化性は、高温における酸素との化学反応に対する材料の耐性を定義する重要な特性です。タングステンカーバイド(WC)工具において、耐酸化性は工具寿命、表面安定性、そして高温産業用途への適合性を決定する上で重要な役割を果たします。この記事では、耐酸化性とは何か、なぜ重要なのか、そしてタングステンカーバイド工具の性能にどのような影響を与えるのかを探ります。耐酸化性とは?耐酸化性とは、特に高温において、酸素にさらされた際に材料が化学的劣化に耐える能力を指します。酸化が起こると、材料表面が空気中の酸素と反応し、酸化物を形成します。[…]

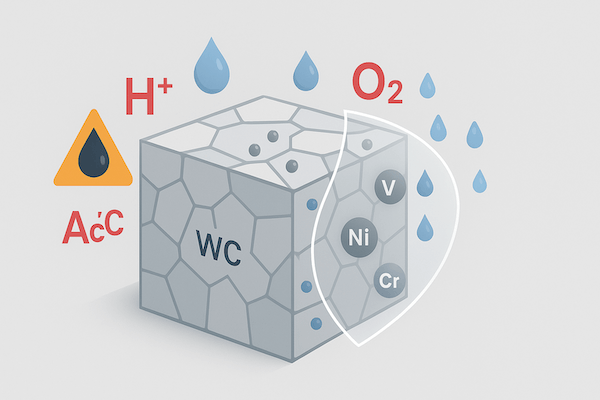

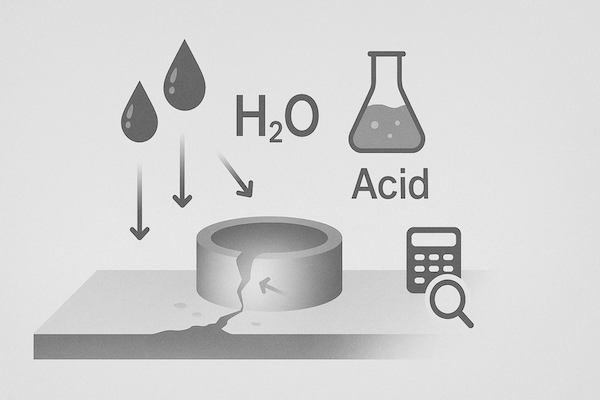

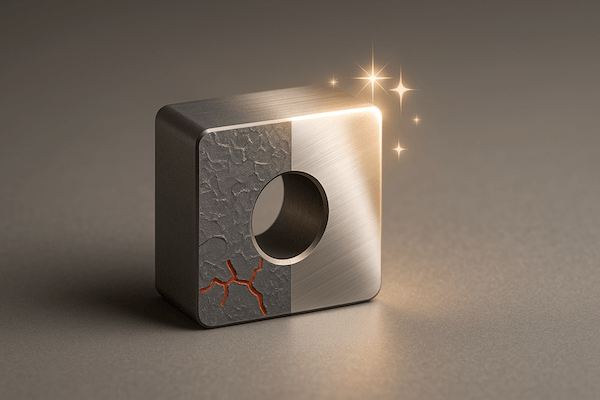

炭化タングステン工具の耐食性について

耐食性とは?耐食性とは、湿気、酸、アルカリ、塩、ガスなど、環境との相互作用によって引き起こされる化学的劣化に対する材料の耐性を指します。腐食は通常、酸化、孔食、表面侵食、そして最終的には材料構造の脆弱化につながります。高い耐食性を持つ材料は、過酷な化学物質にさらされても、機械的完全性、寸法安定性、そして表面仕上げを維持します。なぜ耐食性が重要なのでしょうか?多くの産業用途において、工具や部品は以下のような腐食性環境で使用されます。海水または海洋環境、酸性またはアルカリ性プロセス流体、高湿度の工業プラント、石油、ガス、または化学精製所。腐食は工具の強度を低下させ、精度を低下させ、摩耗を促進し、さらには[…]

炭化タングステン工具のバインダー材料について

先端材料の世界において、バインダー材はタングステンカーバイド(WC)工具の製造において最も重要な要素の一つです。タングステンカーバイド自体は優れた硬度と耐摩耗性で知られていますが、これらの工具に靭性、耐久性、そして構造的完全性を与えるのはバインダー材です。この記事では、バインダー材とは何か、どのように機能するのか、そしてなぜ超硬合金工具に不可欠なのかを探ります。バインダー材とは?バインダー材とは、焼結中にタングステンカーバイド(WC)粒子を結合させるために使用される金属相(通常はコバルト(Co)またはニッケル(Ni))を指します。WCは極めて高い硬度と耐摩耗性を提供する一方、バインダーは[…]

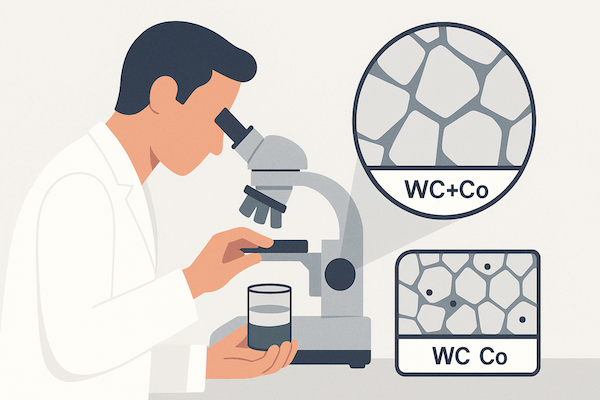

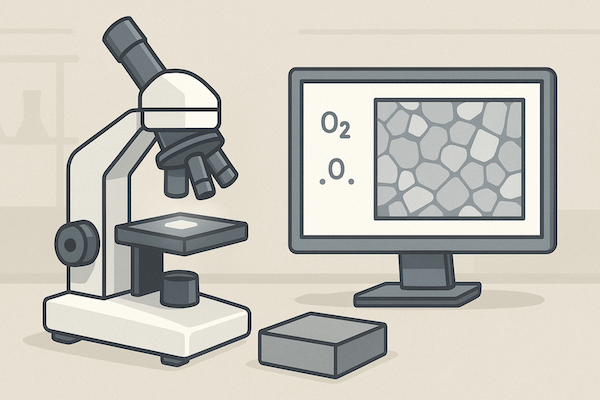

炭化タングステン工具の金属組織学を理解する

金属組織学は、金属および合金の微細構造を研究する科学的手法であり、タングステンカーバイド工具の開発、品質保証、および故障解析において重要な役割を果たします。超硬合金の分野では、金属組織学は、結晶粒度、相分布、気孔率、バインダーの完全性に関する重要な知見を提供します。これらはすべて、超硬工具の性能と信頼性に直接影響します。金属組織学とは?金属組織学は、顕微鏡検査技術を用いて金属および合金の構造と特性を研究する学問です。切断、マウント、研削、研磨、エッチングといった一連の準備工程を経て、光学顕微鏡または電子顕微鏡で観察します。タングステンカーバイド(WC)のような超硬合金の場合、[…]

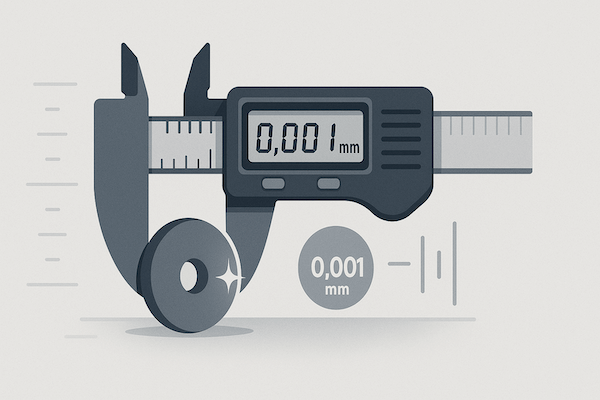

タングステンカーバイド工具における精密測定の理解

精密測定は現代の製造業、特にタングステンカーバイド工具の製造と品質管理において不可欠な要素です。最も硬く耐摩耗性に優れた材料の一つであるタングステンカーバイド(WC)は、厳しい公差、寸法精度、表面品質が絶対条件となる業界で使用されています。この記事では、精密測定とは何か、なぜそれがカーバイド工具業界において重要なのか、そして最適な性能を確保するためにどのような方法が用いられているのかを探ります。精密測定とは?精密測定とは、高精度の機器と方法を用いて、部品の正確な寸法、形状、表面仕上げ、公差を測定することを指します。タングステンカーバイド工具の場合、[…]

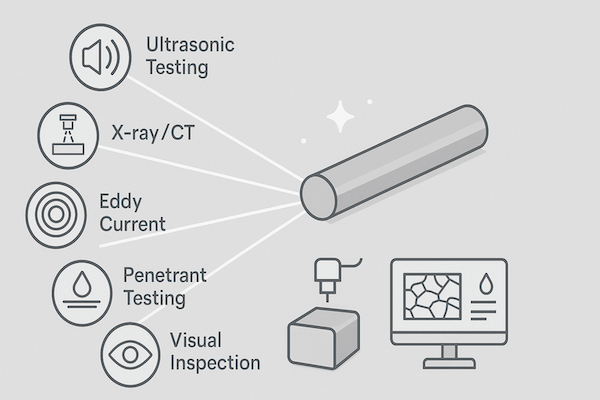

タングステンカーバイド工具の非破壊検査について

非破壊検査(NDT)は、材料や部品の内部および表面の健全性を、損傷を与えることなく評価する重要な品質保証手法です。信頼性、性能、精度が最も重要となるタングステンカーバイド工具の世界では、NDTは各部品が厳格な品質基準と安全基準を満たしていることを確認する上で重要な役割を果たします。非破壊検査とは?非破壊検査とは、エンジニアやメーカーが部品の使い勝手を損なうことなく検査、測定、評価できる一連の分析技術を指します。これは、金属切削、採掘、金型製造など、高精度かつ高応力の環境でよく使用されるタングステンカーバイド(WC)工具にとって特に重要です。一般的なNDT […]

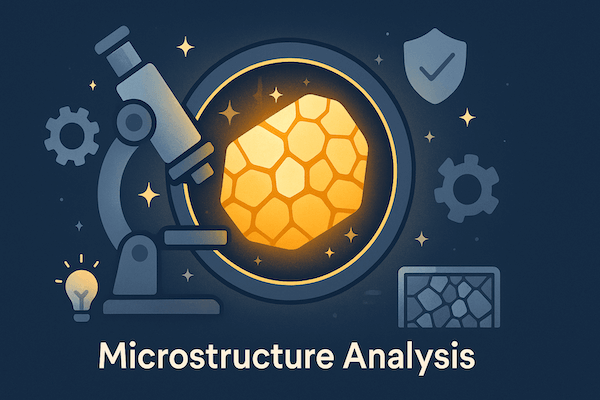

炭化タングステン工具の微細構造分析の理解

微細構造分析は、金属や複合材料の内部構造を詳細に研究することを可能にする材料科学における重要な技術です。切削、採掘、耐摩耗性、精密加工などの用途で広く使用されているタングステンカーバイド工具において、微細構造分析は品質管理、性能最適化、そして故障防止において中心的な役割を果たしています。微細構造分析とは?微細構造分析とは、材料の内部構造を顕微鏡レベルで調べることを指し、通常は光学顕微鏡、走査型電子顕微鏡(SEM)、さらには電子後方散乱回折(EBSD)などの高度な技術を用いて行われます。タングステンカーバイド(WC)ベースの材料では、微細構造分析によって以下のことが明らかになります。WCの粒径と形態、金属バインダー相(通常はコバルトまたはニッケル)の分布、そして[…]

炭化タングステン工具の表面仕上げについて

高性能産業用工具、特にタングステンカーバイド製の工具において、表面仕上げは単なる見た目の美しさではなく、工具の性能、寿命、そして用途への適合性に直接影響を与える重要な技術的要素です。この記事では、表面仕上げの意味、超硬合金工具における表面仕上げの重要性、その測定方法、そして製造における最適化方法について解説します。表面仕上げとは?表面仕上げとは、機械加工、研削、研磨後の工具表面の質感と品質を指します。材料表面に存在する微細な凹凸が含まれ、通常はRa(平均粗さ)、Rz(最大プロファイル高さ)、Rt(プロファイル高さ)、A([…])などのパラメータで定量化されます。

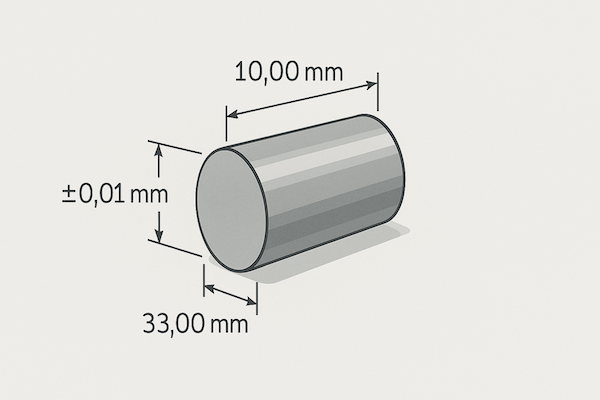

炭化タングステン工具の寸法公差の理解

寸法公差とは?寸法公差とは、製造部品の物理的寸法(長さ、直径、厚さなど)における許容範囲のことです。部品の機能や互換性を損なうことなく、公称寸法からどの程度の偏差が許容されるかを定義します。例えば、公称直径10.00 mm±0.01 mmの超硬合金ロッドの場合、直径は9.99 mmから10.01 mmの範囲であれば許容範囲内とみなされます。なぜ寸法公差が重要なのでしょうか?航空宇宙、自動車、医療、電子機器といった高精度産業では、部品は非常に厳しい制約の中で適合し、機能しなければなりません。わずかな偏差であっても、組み立て上の問題、性能の低下、 […] につながる可能性があります。