タングステンカーバイド産業における熱安定性:概要説明

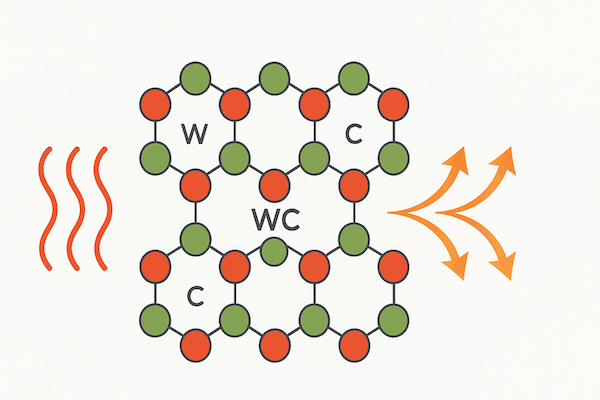

はじめに 先端材料の分野では、タングステン カーバイド (WC) は、その並外れた硬度、耐摩耗性、高融点が際立っています。これらの特性により、炭化タングステン WC は鉱業、航空宇宙、製造業、自動車産業など、さまざまな産業で欠かせない存在となっています。その数多くの有利な特性の中でも、熱安定性は極めて重要な特性であり、過酷な条件下での炭化タングステン コンポーネントの性能と寿命に大きく影響します。炭化タングステンの熱安定性を理解することは、炭化タングステン カーバイドの用途を最適化し、現代の産業プロセスの厳しい要件を満たすために不可欠です。この記事では、炭化タングステン カーバイド業界における熱安定性の概念を掘り下げ、その重要性、基礎となるメカニズム、それに影響を与える要因などを探ります。[…]

タングステンカーバイド産業における多孔性:概要説明

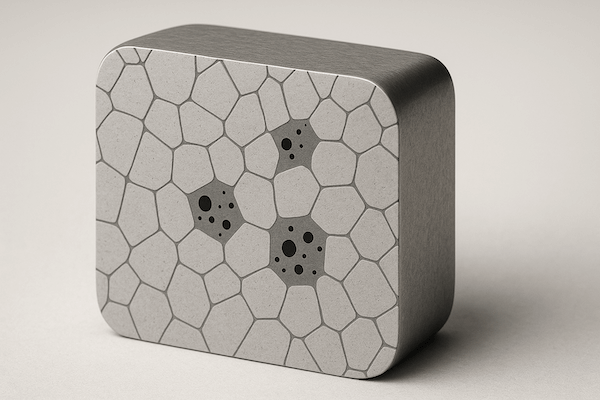

はじめに 気孔率は材料科学において重要な概念であり、特に工業用工具に使用されるタングステンカーバイド(WC)のような高性能材料においては重要です。見落とされがちですが、気孔率は超硬工具の機械的強度、耐摩耗性、そして全体的な信頼性を左右する重要な役割を果たします。この記事では、気孔率とは何か、どのように形成されるのか、なぜ重要なのか、そしてメーカーがどのように管理しているのかを解説します。気孔率とは? 気孔率とは、材料内部に微細な空隙や気孔が存在することを指します。これらの空隙は顕微鏡でしか見えない場合もあれば、肉眼で確認できる場合もあり、製造工程における緻密化が不完全な場合に発生します。超硬合金において、気孔率は未充填の空間を指します[…]

炭化タングステン工具の粒度について

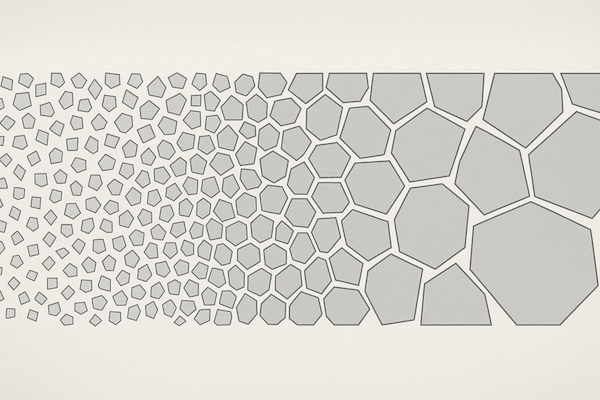

先端材料と工具の世界では、「粒度」という言葉が頻繁に登場します。冶金学者だけが関心を持つ詳細事項のように聞こえるかもしれませんが、鉱業、機械加工、石油・ガス、精密製造業などで使用されるタングステンカーバイド工具の性能、強度、耐久性において、粒度は重要な役割を果たします。では、粒度とは何でしょうか?そして、なぜ気にする必要があるのでしょうか?粒度とは?粒度とは、セメントカーバイド材料に含まれる個々のタングステンカーバイド(WC)粒子の平均サイズを指します。これらの粒子は、金属結合剤(通常はコバルトまたはニッケル)によってしっかりと結合され、優れた硬度と強度を持つ複合材料を形成します。粒度[…]

炭化タングステン工具の合金元素について

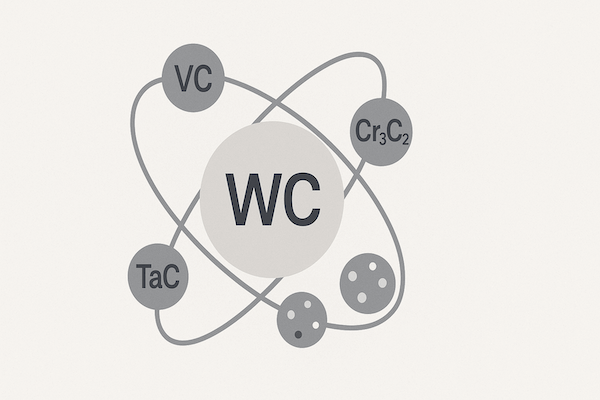

タングステンカーバイド工具は、その卓越した硬度、耐摩耗性、そして過酷な作業条件への耐性で知られています。しかし、この優れた性能の裏には、WCとコバルトだけではありません。厳選された合金元素も含まれています。これらの微量添加物は、たとえ微量であっても、工具の挙動、耐久性、そして微細組織制御に大きな影響を与えます。この記事では、合金元素とは何か、なぜ添加されるのか、そして超硬合金工具の性能にどのような影響を与えるのかを探ります。合金元素とは?材料科学において、合金元素とは、母材金属または複合材料の特性を変化させるために意図的に少量添加される元素のことです。[…]