炭化タングステン切削工具の寿命を延ばすためのメンテナンスのヒント

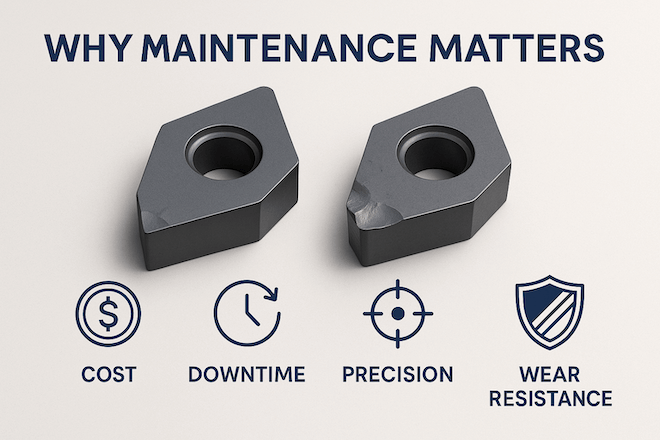

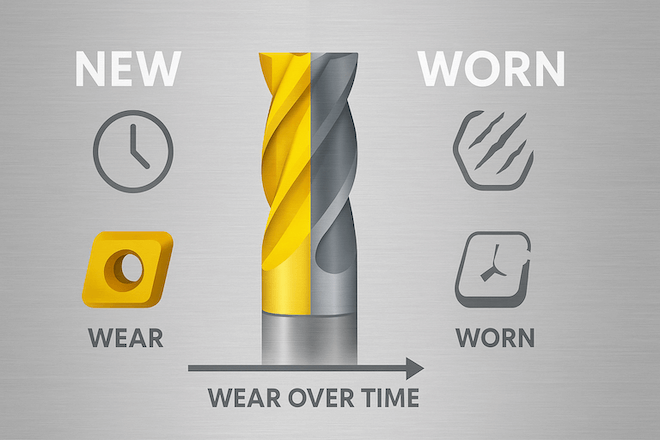

タングステンカーバイド切削工具は、その硬度、強度、耐摩耗性で知られています。しかし、どんなに頑丈な工具であっても、より長く使い続け、より優れた性能を発揮するには適切なメンテナンスが必要です。適切なメンテナンスを行うことで、ダウンタイムの削減、コスト削減、そして生産品質の向上につながります。この記事では、タングステンカーバイド切削工具の寿命を延ばすための、シンプルで効果的なメンテナンスのヒントをご紹介します。金属切削、木工、穴あけなど、どのような用途でも、これらのヒントは工具への投資を最大限に活用するのに役立ちます。メンテナンスが重要な理由 タングステンカーバイド工具は、高速、高熱、高圧の環境でよく使用されます。時間の経過とともに、摩耗、欠け、破損が生じる可能性があります[…]

炭化タングステン切削工具が優れた耐摩耗性を持つ理由

現代の製造業において、適切な切削工具を選ぶことは非常に重要です。工具は強度、精度、そして長寿命が求められます。タングステンカーバイド切削工具が産業界から信頼されているのは、優れた耐摩耗性という大きな理由があります。このブログでは、タングステンカーバイドの優れた強度、他の素材よりも長持ちする理由、そして様々な業界でのメリットについて解説します。高性能工具をお探しなら、この記事がタングステンカーバイドが賢明な選択である理由を理解するのに役立ちます。耐摩耗性とは?耐摩耗性とは、工具が長期間使用しても、どれだけ強度と鋭さを維持できるかを意味します。工具が材料を切断、穴あけ、研磨する際には、[…]

切削工具用途における炭化タングステングレードの理解

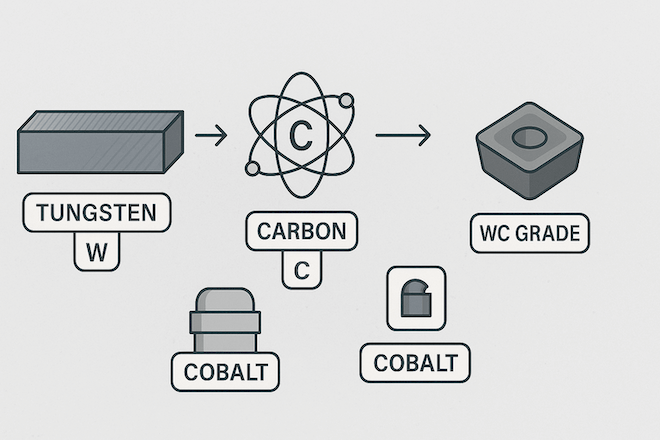

はじめに:タングステンカーバイド工具におけるグレードの重要性 タングステンカーバイド切削工具を使用する際は、グレードを理解することが重要です。グレードは工具の硬度、靭性、そして最適な用途を定義します。このガイドは、タングステンカーバイドグレードとは何か、なぜ重要なのか、そして適切なグレードを選ぶ方法を理解するのに役立ちます。タングステンカーバイドグレードとは?タングステンカーバイドグレードは、WC粒子(タングステンカーバイド)とバインダーメタル(通常はコバルト)の組み合わせです。これらの材料の比率とサイズによって、工具の強度と性能が決まります。例えば、WCが高いほど硬度が高くなります。コバルトが多いほど靭性が高くなります。グレードはYG6、YG8、YG10Xのように分類されます。各グレードはそれぞれ異なる用途向けに作られています。[…]