高品質の炭化タングステン切削工具の見分け方

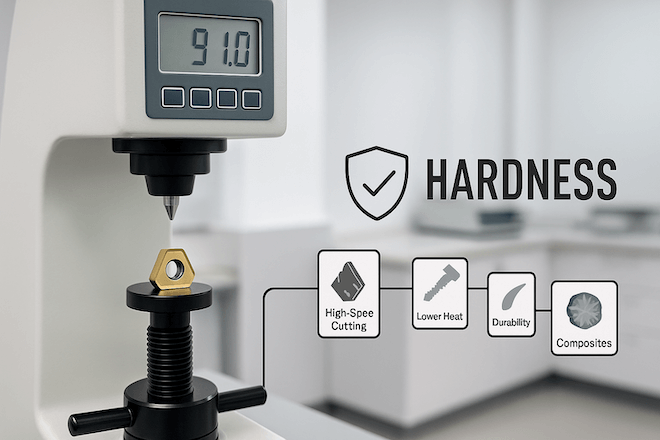

タングステンカーバイド切削工具は、硬く、耐久性があり、長持ちするため、多くの業界で使用されています。しかし、すべての超硬工具が同じというわけではありません。品質の悪い工具は、摩耗が早く、破損したり、仕上がりが悪くなったりすることがあります。このガイドは、購入または使用する前に、タングステンカーバイド切削工具の品質を確認する方法を理解するのに役立ちます。1. 工具の硬度を確認する 優れたタングステンカーバイド切削工具を見分ける最も重要な指標の一つは、その硬度です。硬度の高い工具は切れ味が長持ちし、硬い材料を切削できます。高品質の超硬工具のほとんどは、硬度(HRA)が89~93です。硬度が低い工具は摩耗が早く、[…]

炭化タングステン切削工具の性能向上におけるコーティングの役割

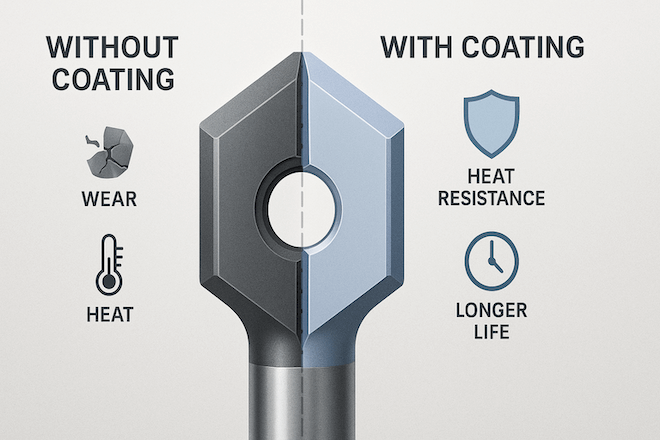

タングステンカーバイド切削工具は、金属加工、木工、航空宇宙、金型製造などの業界で広く使用されています。強度と耐摩耗性に優れ、硬い材料を切削できます。しかし、これらの工具であっても、時間の経過とともに摩耗したり破損したりすることがあります。そこで工具コーティングが役立ちます。優れたコーティングは、工具寿命の延長、性能向上、コスト削減に役立ちます。この記事では、コーティングの仕組み、使用されるコーティングの種類、そしてタングステンカーバイド切削工具から最高の結果を得るためにコーティングが重要な理由について説明します。タングステンカーバイド工具にとってコーティングが重要な理由 タングステンカーバイドは既に硬い材料ですが、それでもタングステンカーバイドで作られた切削工具は[…]

炭化タングステン切削工具の一般的な問題と解決策

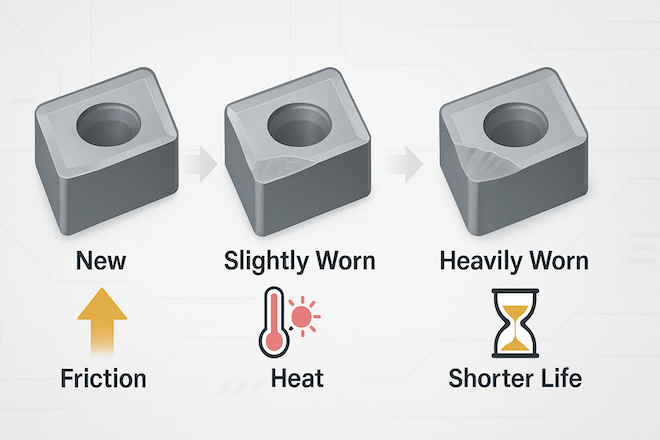

タングステンカーバイド切削工具は、その強度、硬度、長寿命で知られています。しかし、これらの高性能工具であっても、使用中に問題が発生することがあります。よくある問題を理解し、その解決方法を知ることで、工具寿命を延ばし、廃棄物を削減し、円滑な作業運営を維持することができます。このブログでは、タングステンカーバイド切削工具によくある問題を取り上げ、効果的なシンプルな解決策をご紹介します。金属、木材、複合材料など、どのような材料を切断する場合でも、このガイドはミスを防ぎ、工具の性能を最大限に引き出すのに役立ちます。1. 工具の摩耗が早すぎる 🛠 問題:タングステンカーバイドは硬いにもかかわらず、刃先が摩耗することがあります […]